Complex contour defect verification method based on point cloud three-dimensional reconstruction

A technology of three-dimensional reconstruction and verification method is applied in the field of point cloud complex contour defect verification to achieve the effects of improving model accuracy, reducing complexity and improving registration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] The technical solution of the complex contour defect verification method based on point cloud three-dimensional reconstruction provided by this application will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand this application and implement it.

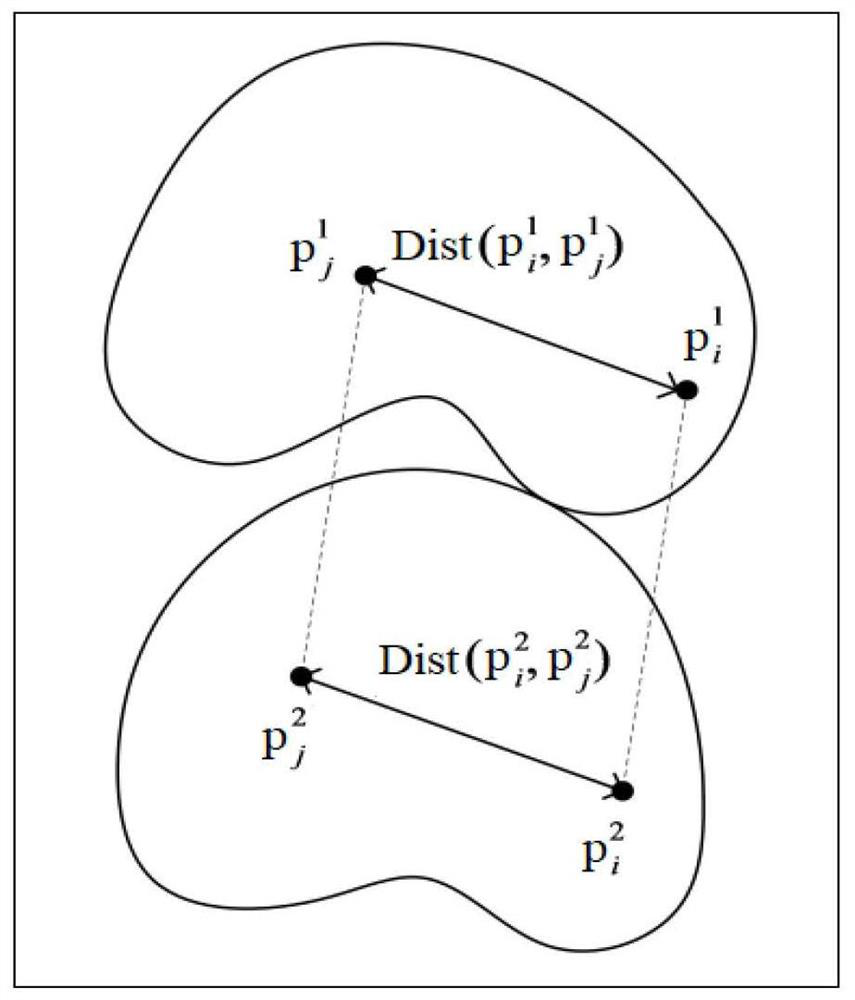

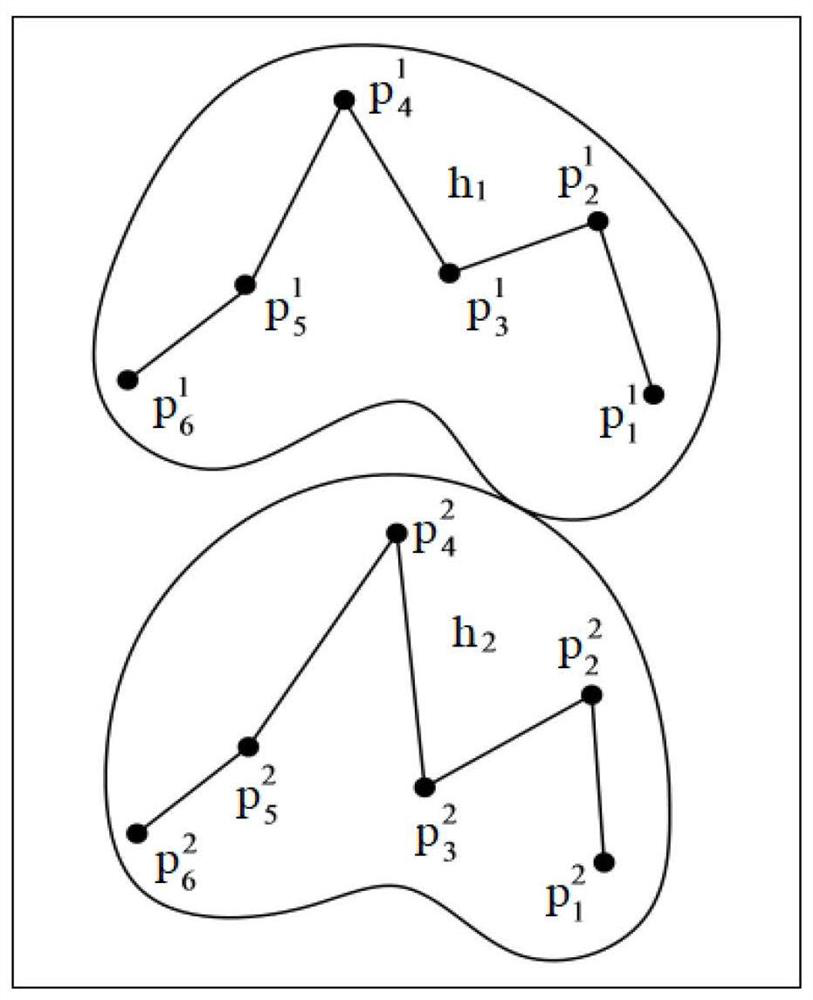

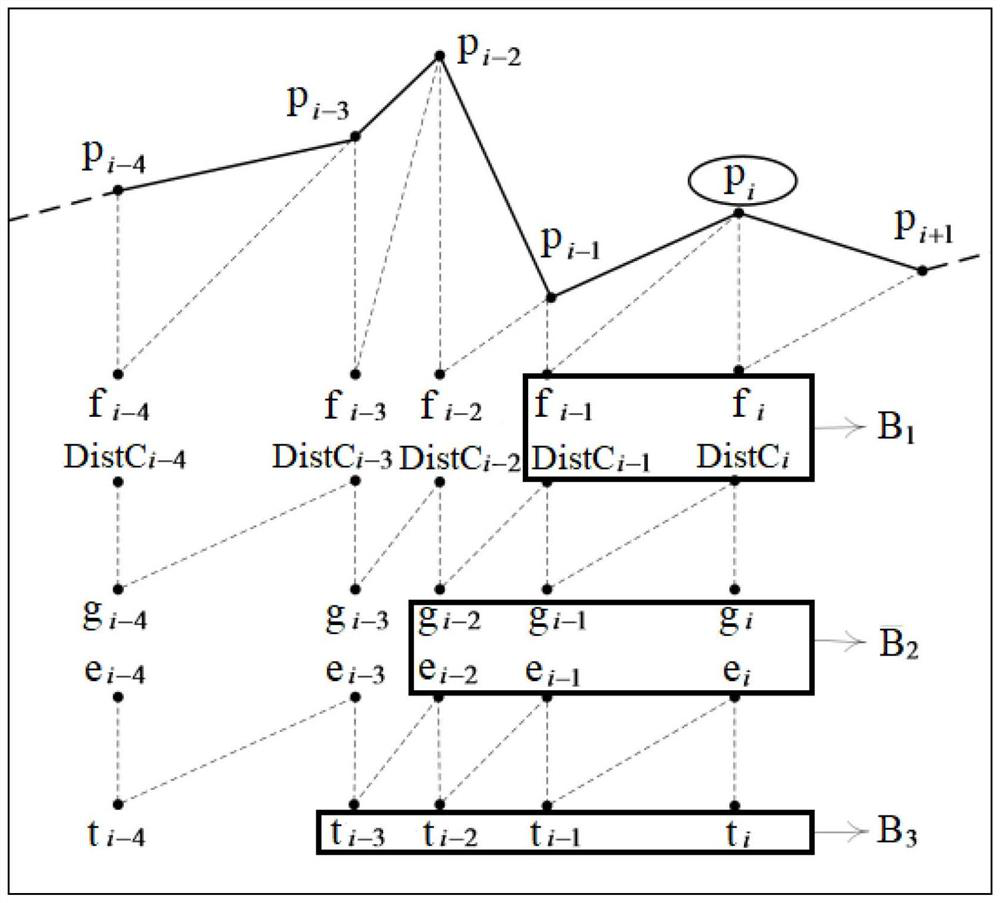

[0122] The geometric diversity of complex contours, the diversity of coating types, and the uncertainty of random defects have brought great difficulties to the defect verification work, making it difficult to obtain defect verification methods based on 3D reconstruction of point clouds in the existing technology. Satisfactory verification effect. In order to solve the problem that the traditional point cloud is not effective in the face of complex contours, this application improves and optimizes the point cloud pre-processing, registration, surface reconstruction and defect verification methods , not only optimizes the fast and fine 3D reconstructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com