A kind of micro swing motor and its preparation method

A swing motor, miniature technology, applied in the direction of electric components, electric vehicles, manufacturing motor generators, etc., can solve the problems of difficult assembly, poor reliability of circuit connection, difficult disassembly and maintenance, etc., to achieve easy assembly and simplified structure The effect of designing and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

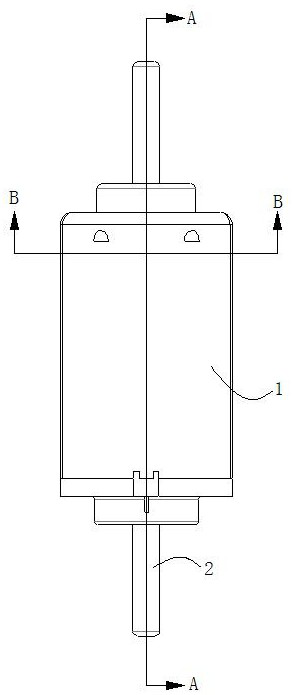

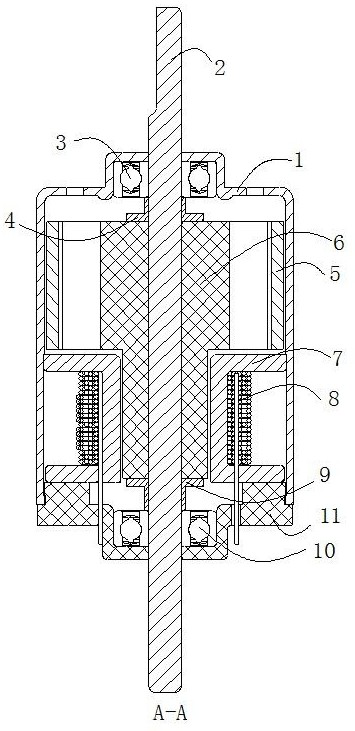

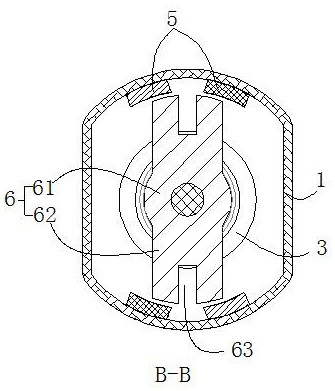

[0042] See Figure 1-Figure 6 , the micro-swing motor provided by the embodiment of the present invention includes a stator part and a rotor part, and the stator part is composed of a casing 1, two pairs of permanent magnets 5 and a rear end cover 11 respectively arranged on the casing 1, wherein The two pairs of permanent magnets 5 are arranged on the inner side of the casing 1 at intervals in the axial direction; 8. It is composed of a coil bobbin 7, wherein the magnetic conductive magnetic core 6 is a magnetic conductive magnetic core with a "T" shape in axial section, and the head of the magnetic conductive magnetic core 6 is a rectangle whose length direction is perpendicular to the rotating shaft 2 The magnetic core head 61, the tail part of the magnetic core 6 is the magnetic core column part 61 whose length direction is parallel to the rotating shaft 2, and the magnetic core head 61 and the magnetic core column part 61 are integrated, and its axial position is provided...

Embodiment 2

[0076] see Figure 7-Figure 12 , the micro-swing motor and the preparation method thereof provided in this embodiment are basically the same as those in Embodiment 1, except that:

[0077] Specifically, protruding portions 64 for increasing the magnetic flux rate of the magnetic core head 62 are further provided on both sides of the magnetic core head portion 62 in the circumferential direction along the width direction of the magnetic core head portion 62 .

[0078] In this embodiment, the protruding part 64 and the magnetic core head 62 are integrally formed, and the cross section of the protruding part 64 is rectangular; under the condition that the lateral length of the magnetic core head 62 remains unchanged, the The protrusions arranged along the width direction on both sides of the circumferential direction can effectively increase the overall magnetic flux area of the magnetic core head, improve the magnetic flux rate of the magnetically conductive magnetic core, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com