Crushing device with dust removal function for rice processing

A technology of a rice processing and pulverizing device, which is applied in the directions of cleaning methods and utensils, cleaning methods using liquids, and arrangement of drying gases, etc., can solve the problems of inability to screen rice, inability to wash and air dry rice, and incompletely pulverized rice, and achieve convenient collection. , reducing pressure, crushing completely and fully

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

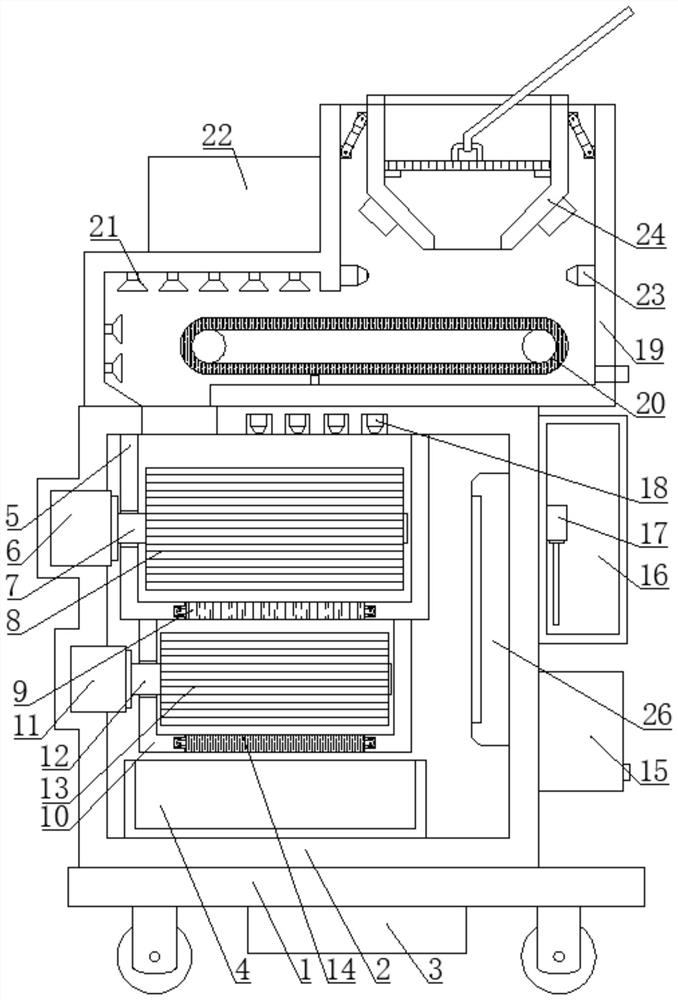

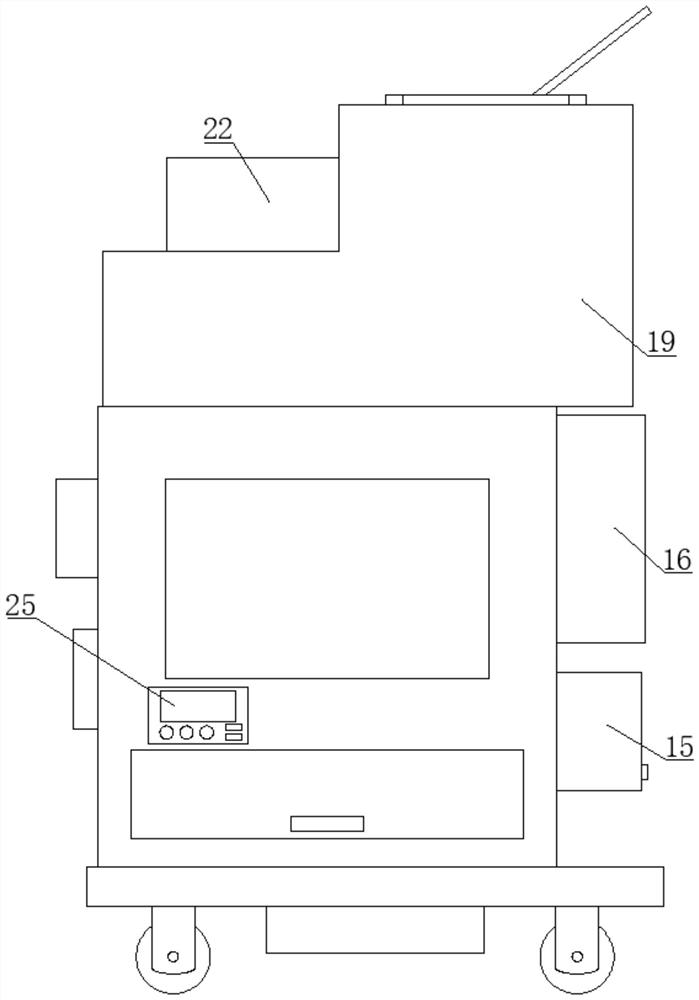

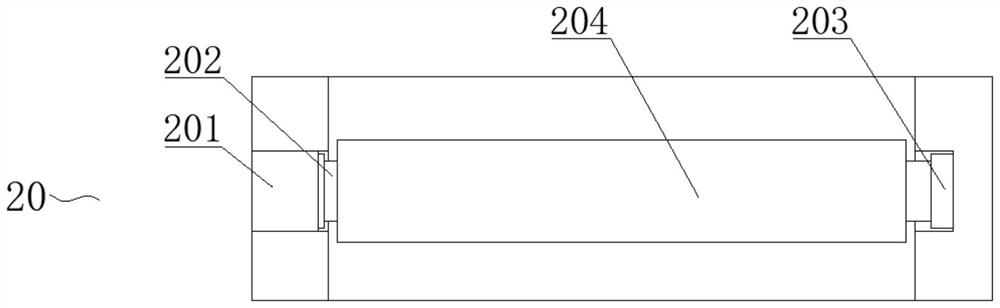

[0024] see Figure 1-4 , the present invention provides the following technical solutions: a crushing device with dust removal function for rice processing, comprising a base 1, the top of the base 1 is fixedly connected with a first box 2, and the top of the inner wall of the first box 2 is fixedly connected with a first The crushing box 5, the bottom of the first crushing box 5 is fixedly connected with the second crushing box 10, the inner wall side of the first casing 2 is fixedly connected with two first motors 6 and two second motors 11, two first The output ends of the motor 6 are all fixedly connected with the first rotating shaft 7, and the other ends of the two first rotating shafts 7 respectively pass through the first crushing box 5 and are positioned in the first crushing box 5, by setting the first crushing box 5, the first Motor 6, the first gear roller 8 and the first filter plate 9 are convenient to pulverize the rice, the outer surfaces of the two first rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com