Automatic small hardware cutting machine and cutting method thereof

A cutting machine and small hardware technology, applied in metal processing, metal processing equipment, feeding devices, etc., can solve the problems of low yield rate of hardware parts, so as to enhance market competitiveness, improve product yield and efficiency, and save personnel cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

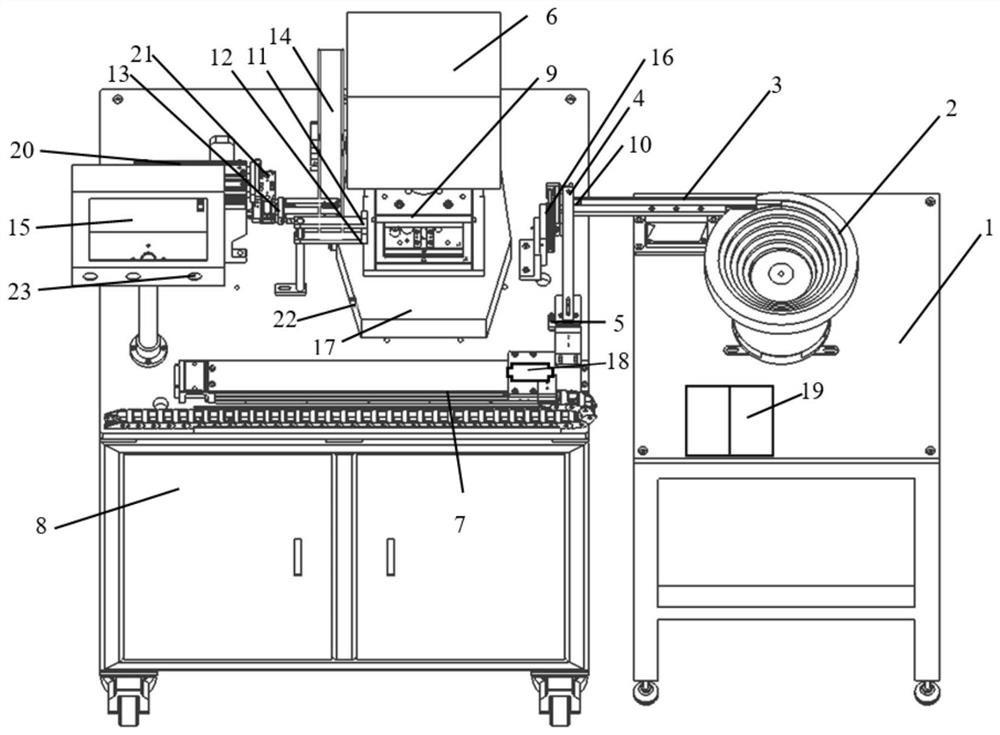

[0027] Example 1 figure 1 It is given, a small hardware automatic cutting machine, including a table 1, and a first controller 19 on one side on the table, and a vibration plate 2 is provided on the other side, the vibrating plate 2 includes a straight feeder, a linear feeder The middle is equipped with a first inductor 3. The end of the line feeder is connected to the automatic pusher 16. The vibrating plate 2 can vibrate feed, and send the product to be cut to the automatic pusher 16 through the line feeder to automatically push The material 16 is adjacent to the first suction nozzle 4 of the first cylinder 5, and the other end of the first cylinder 5 is connected to the servo module 7, and the servo module 7 is provided with a distribution box 8, and the servo module 7 is fixedly installed. On one side of the assembler 8, a fixing frame 17 is attached to one side of the distribution box 8, and a press mold 9 is provided. The upper end of the stamping die 9 is connected by a fix...

Embodiment 2

[0028] In an embodiment, the line feeder is provided with a fourth sensor 10, and the fourth sensor 10 is adjacent to the automatic pusher 16, and the product reaches the end of the line feeder, fourth The inductor 10 senses a product, transmitting information to the automatic pusher 16, and the automatic pusher 16 will push the product to the designated position, and the vibrating plate 2 realizes the automatic feeding of the product.

Embodiment 3

[0029] In the case of the first example, the servo module 7 is provided with a vacuum generator 18, the first cylinder 5, the second cylinder 13, the third cylinder 20, and the fourth cylinder 21, which are occurring by vacuum. Generate generated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com