Modularized cutter bar with replaceable head module

A modular, head technology, applied in the components of boring machine/drilling machine, drilling/drilling equipment, drilling tool accessories, etc., can solve the problems of deep hole processing, drill pipe damage, high cost, and achieve high processing stability , long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

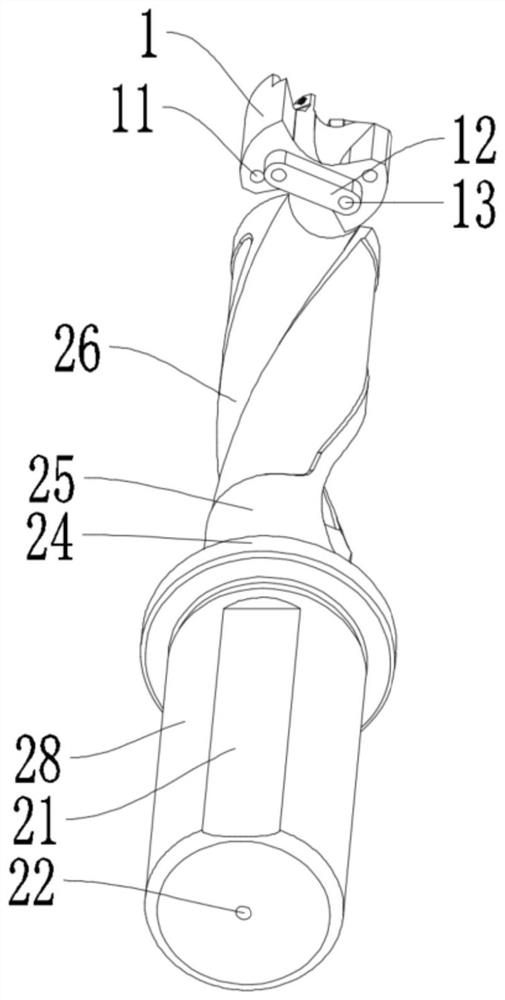

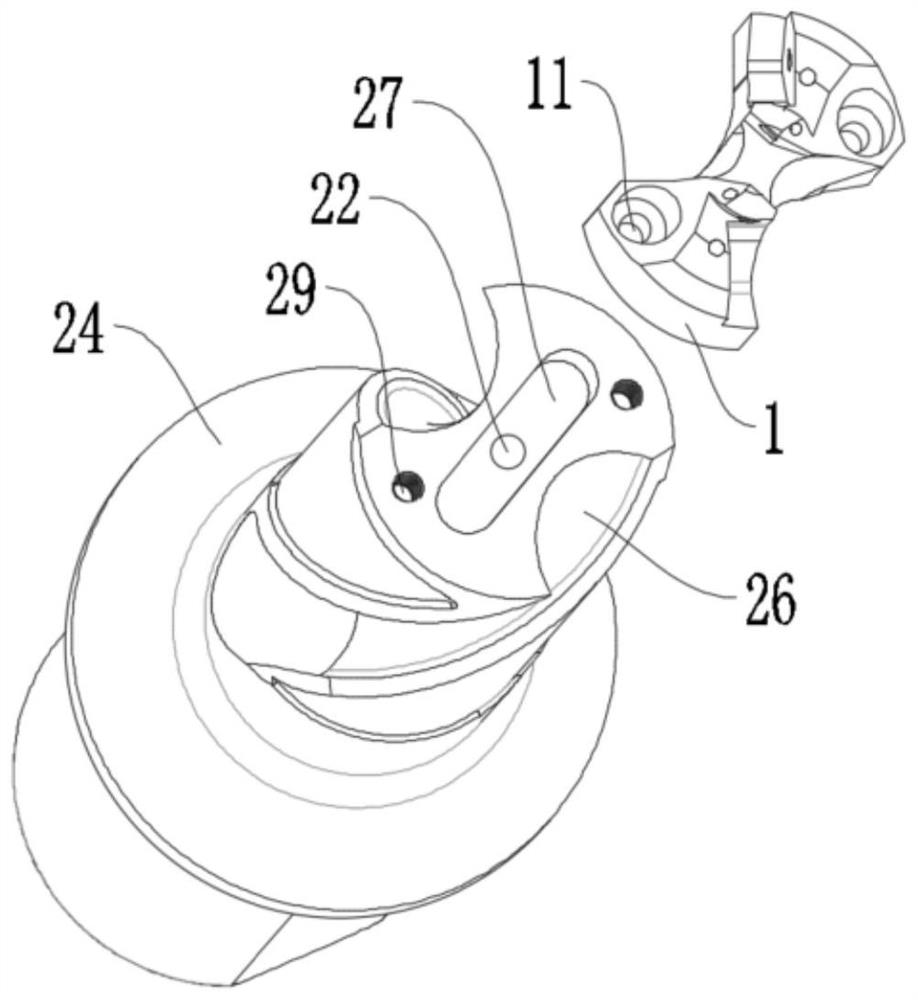

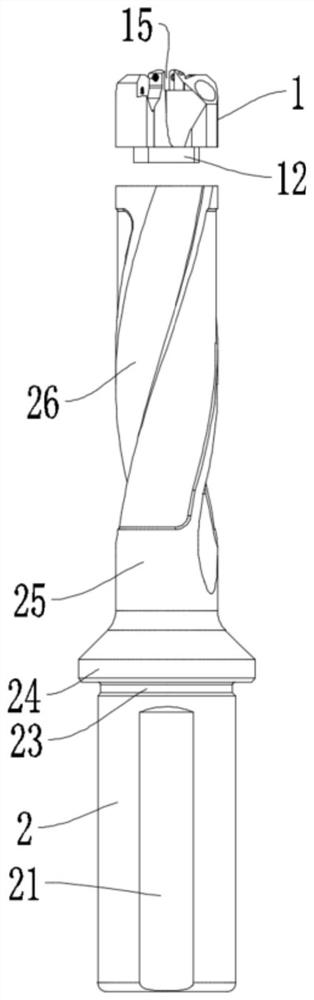

[0037] A modular toolholder with interchangeable head modules such as Figure 1-6 As shown, it includes a cutter body 2 and a head module 1 installed on the cutter body 2, a cutter head and a blade are installed on the head module 1; the cutter body 2 includes a clamping part 28 and a connecting part 25, so The surface of the connecting portion 25 is provided with at least one second spiral groove 26, and the top end of the connecting portion 25 is provided with a waist-shaped groove 27 and a fourth positioning hole 29, and a through-hole 22 is opened in the waist-shaped groove 27, and the through-hole The hole 22 runs through to the bottom end of the clamping part 28. The diameter of the through hole 22 is 0.1 to 0.4 times the diameter of the head of the cutter body 2. The head of the cutter body 2 is the part of the connecting part 25 close to the head module 1. one end.

[0038] The head module 1 includes a first helical groove 16 and a mounting portion 17, the mounting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com