Radioactive nuclear waste metal smelting and feeding method

A radioactive nuclear waste and metal technology, applied in the direction of emptying containers, loading/unloading, bottle filling, etc., can solve the problems of high labor intensity, respiratory system damage, splashing out, etc., achieve high automation, avoid nuclear radiation, and improve The effect of degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

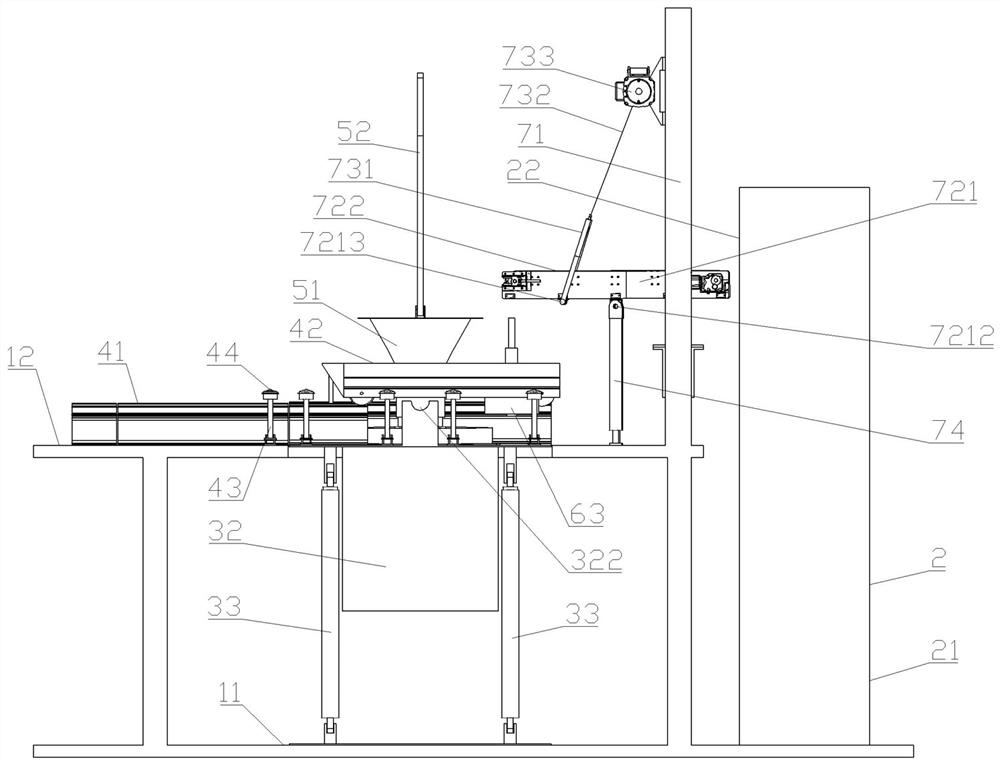

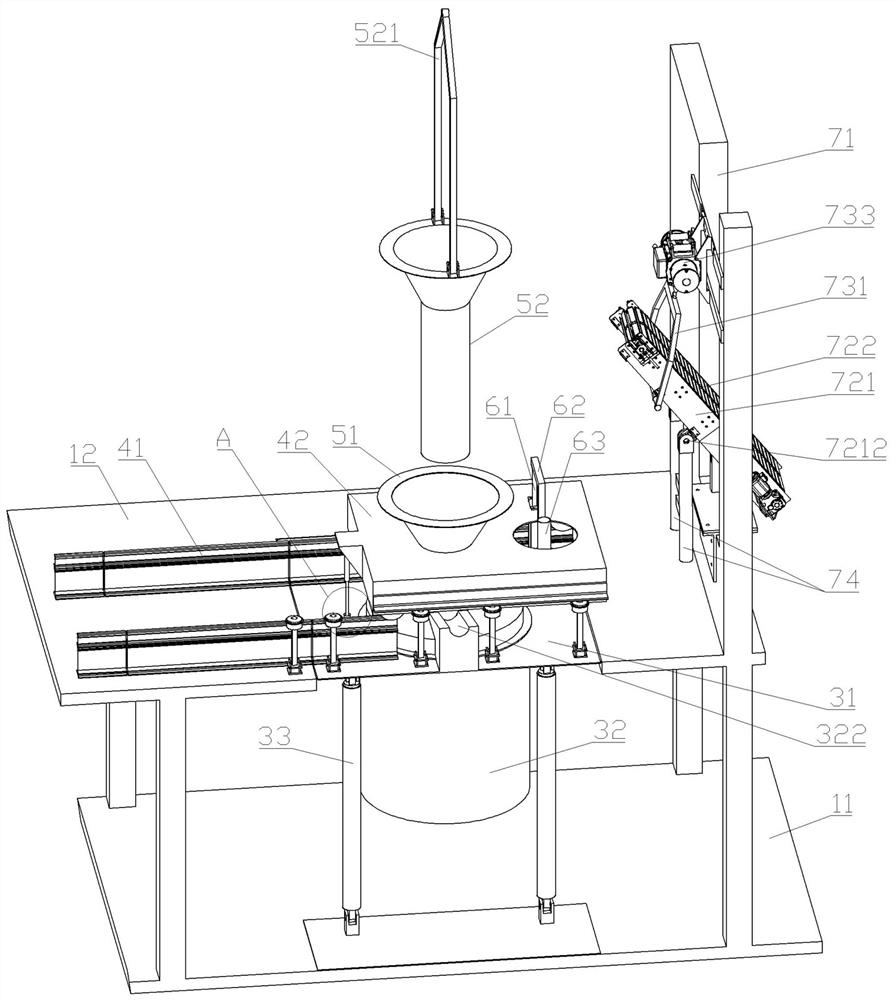

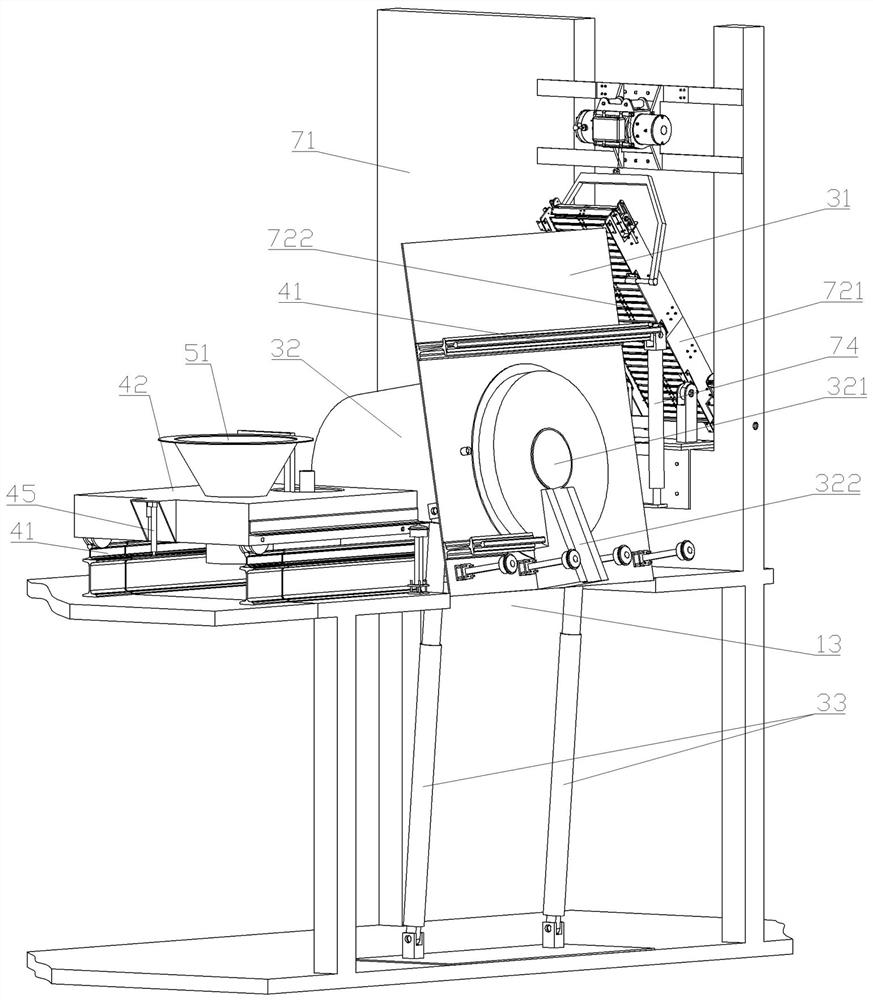

[0059] Such as Figure 1-5 As shown, the radioactive nuclear waste metal smelting and feeding assembly includes a general frame, a vertical hoist 2, a smelting furnace assembly, a trolley assembly, a feeding docking mechanism, a negative pressure dust removal mechanism and a material conveying mechanism.

[0060] The general frame is successively provided with a floor 11 and a second floor 12 from bottom to top. There is a space between the first floor 11 and the second floor 12. The upper end of the second floor 12 is a second floor space. The second floor 12 is provided with A communication port 13 connecting the space on the first floor and the space on the second floor.

[0061] The vertical hoist 2 is fixedly installed on the general frame and is located between the first-floor space and the second-floor space. Its lower end is provided with a material inlet 21 connected to the first-floor space, and its upper end is provided with a material outlet 22 connected to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com