All-water foaming polyurethane raw material composition for polyurethane security door and preparation method of all-water foaming polyurethane raw material composition

A raw material composition and full water foaming technology, which is applied in the field of polyurethane anti-theft doors, can solve the problems of poor dimensional stability of polyurethane anti-theft doors, low applicability of polyurethane anti-theft doors, high core density, etc., and achieve shortened curing reaction time and low cost , the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of described polyurethane anti-theft door all-water foaming polyurethane raw material composition: comprises the following steps:

[0043] (1) Preparation of component A: Stir the polyether polyol A, polyether polyol B, polyether polyol C, foam stabilizer, and catalyst in the formula of component A for 0.5-1.0 hours at room temperature, and mix thoroughly , then add a chemical blowing agent, mix well, and get A component;

[0044] (2) When in use, keep the temperature of components A and B at 20-25°C, mix components A and B at a weight ratio of 1:(1.3-1.5), and inject them into the mold to obtain full water foamed polyurethane anti-theft door material.

Embodiment 1-3

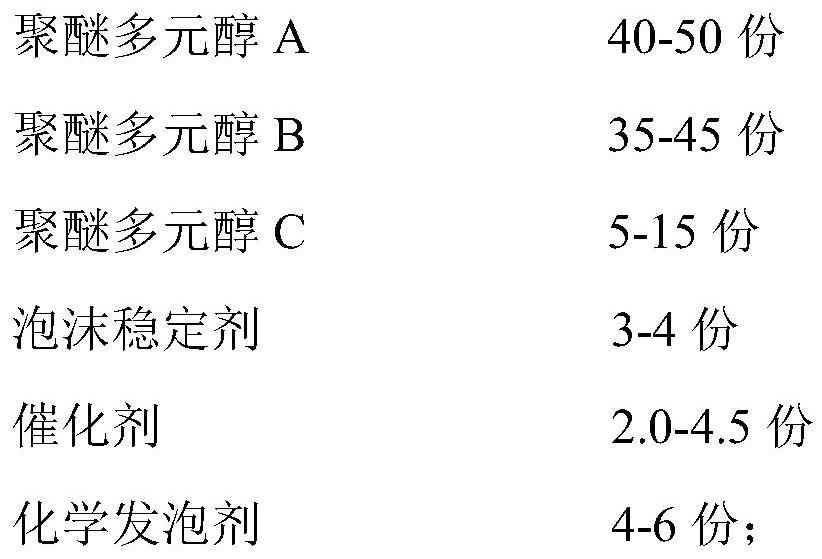

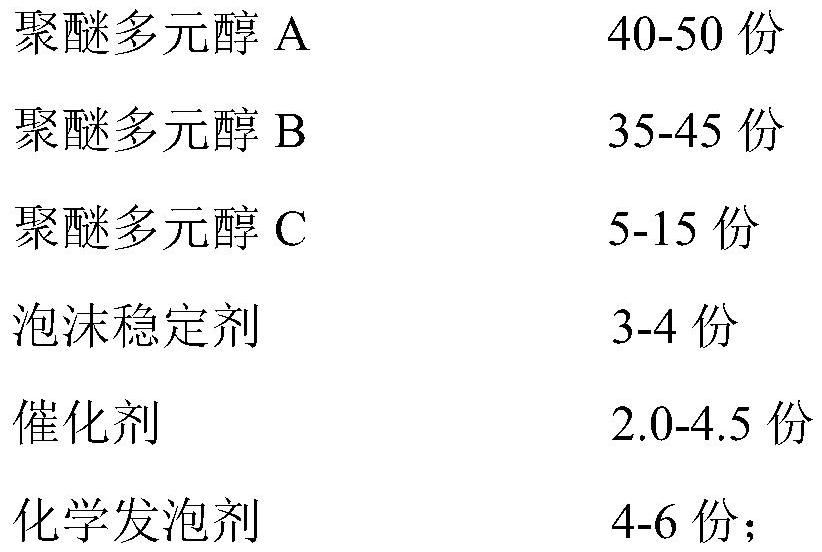

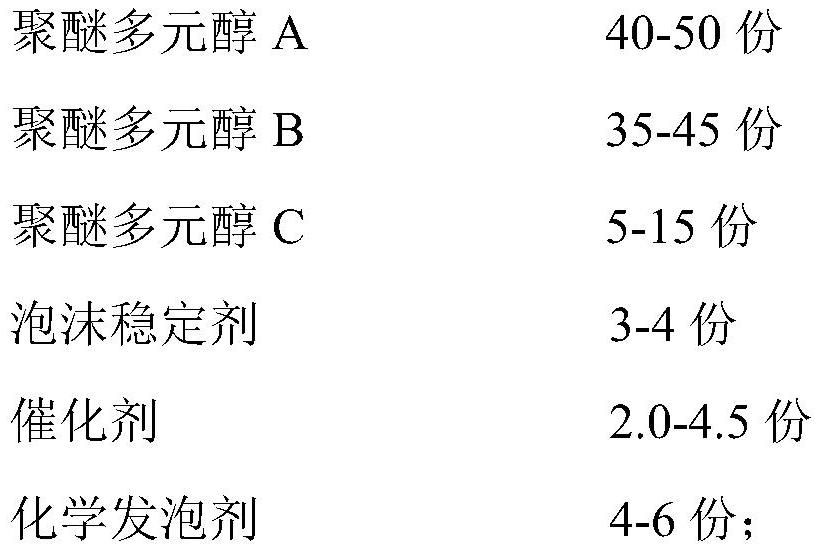

[0053] The full water foaming polyurethane raw material composition and parts by weight of the polyurethane anti-theft door of Examples 1-3 are shown in Table 1 below.

[0054] Raw material components and parts by weight of polyurethane raw material composition in the embodiment 1-3 of table 1

[0055]

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com