Reactor core melt cooling and collecting device

A core melt and collection device technology, which is applied in the field of core trapping, can solve the problems of limited cooling capacity, easy leakage, and large occupied volume, and achieves the effects of improving cooling capacity, high safety and reliability, and less space occupied by the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

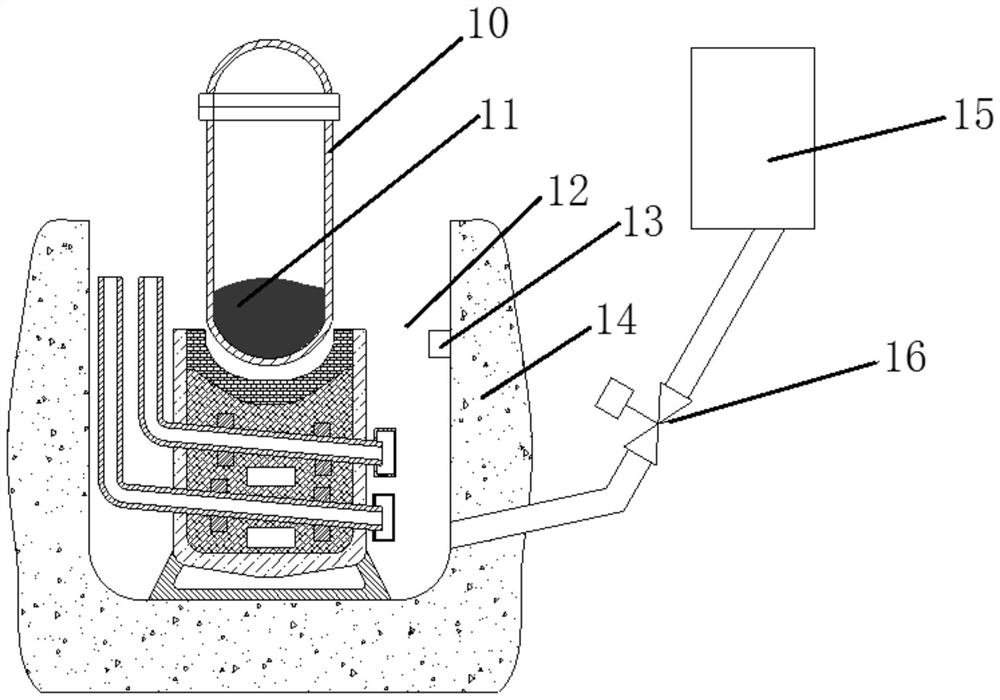

[0046] This embodiment provides a core melt cooling collection device, such as figure 1 As shown, it includes a steel collection container and a stack cavity 14, the steel collection container is arranged in the stack cavity 14 for collecting core melt, and the gap between the steel collection container and the stack cavity 14 forms a cooling cavity 12. The cooling cavity 12 is used to cool the core melt collected in the steel collection vessel.

[0047] The mouth of the reactor cavity is higher than the steel collection vessel, and the area of the mouth of the reactor cavity is larger than that of the steel collection vessel, so as to prevent the core melt from migrating out of the steel collection vessel.

Embodiment 2

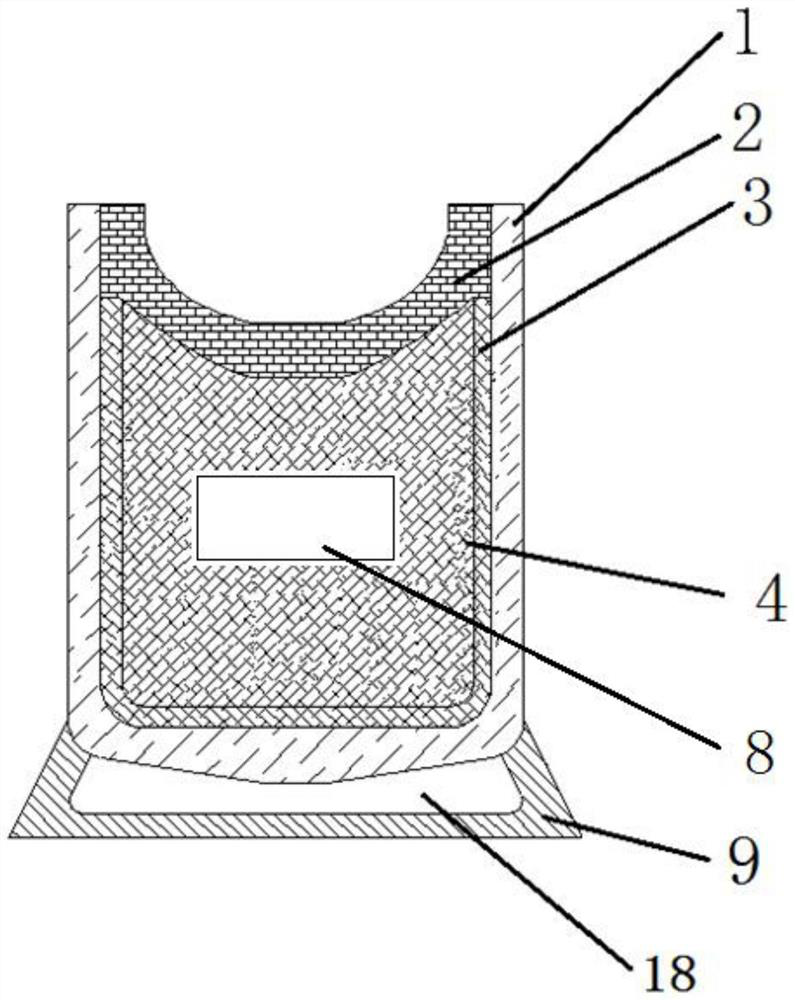

[0049] The difference between this embodiment and the previous embodiment lies in, as Figure 2-Figure 4 As shown, the steel collection container includes: thermal shock protection layer 2, container protection layer 3 and steel container 1;

[0050] Both the container protection layer 3 and the thermal shock protection layer 2 are arranged in the steel container 1, the container protection layer 3 is close to the circumferential inner wall and the bottom inner wall of the steel container 1, and the thermal shock protection layer 2 is arranged in the container protection Above the layer 3, the thermal shock protection layer 2 and the container protection layer 3 form a closed chamber A17, and the top of the thermal shock protection layer 2 is flush with the steel container 1.

[0051] The bottom of the thermal shock protection layer 2 is depressed towards the bottom of the steel container 1 , and the side wall of the shock protection layer 2 is close to the circumferential inn...

Embodiment 3

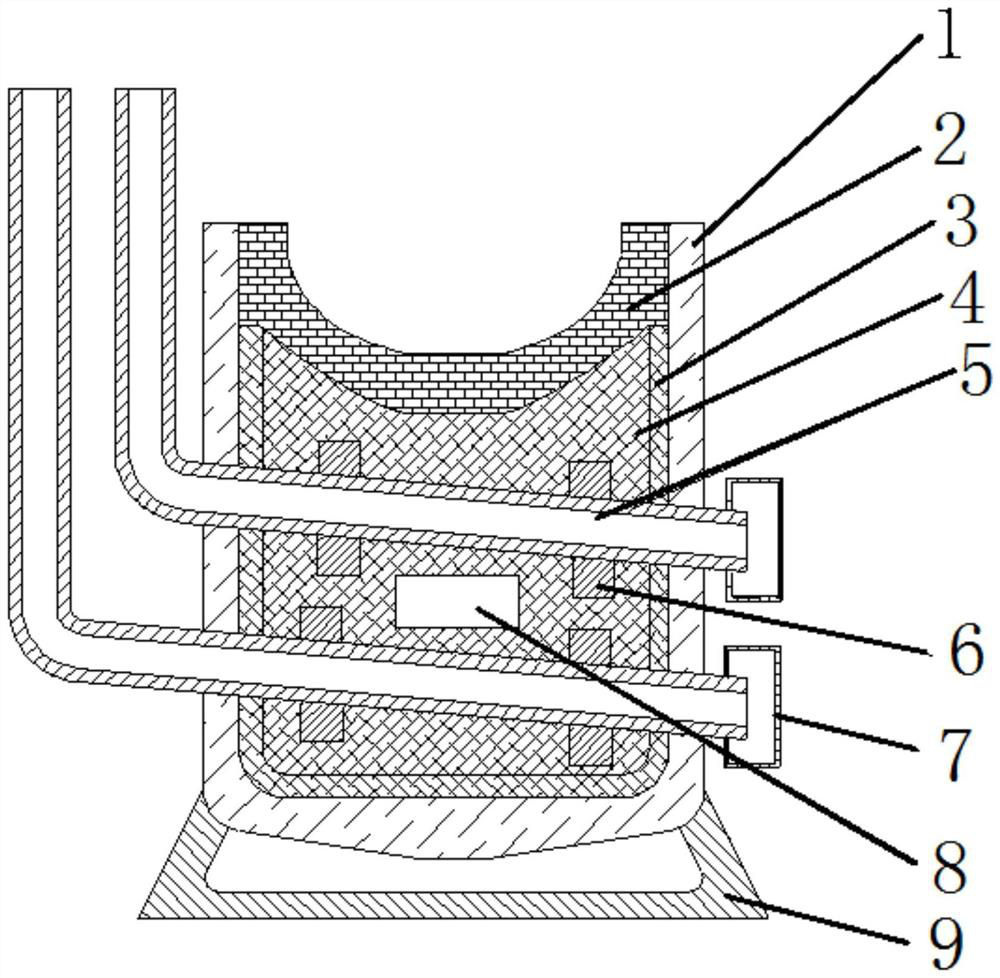

[0054] The difference between this embodiment and the previous embodiment is that it also includes a heat transfer tube 5, a plurality of heat transfer tubes run through the side wall of the steel container 1 and the closed chamber A17, and the heat transfer tubes 5 run through the side wall of the steel container 1 After that, it extends upward along the axis of the steel container, and the extended part of the heat transfer tube is higher than the steel container 1. A filter 7 is installed at the entrance of the heat transfer tube 5, and the height of the heat transfer tube 5 penetrating into the steel container 1 is low. The height at which the heat transfer tube 5 passes out of the steel container 1.

[0055] It also includes a protective wall 4 for the heat transfer tube, and multiple protective walls are installed in parallel in the airtight chamber A, and the protective wall 4 is in contact with the thermal shock protection layer 3;

[0056] A plurality of heat transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com