Fuel cell humidifying system and fuel cell system

A fuel cell and control system technology, applied in the direction of fuel cells, fuel cell additives, fuel cell control, etc., can solve the problems of high cost, complex structure, stack flooding, etc., and achieve high spray atomization quality and simple processing technology , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

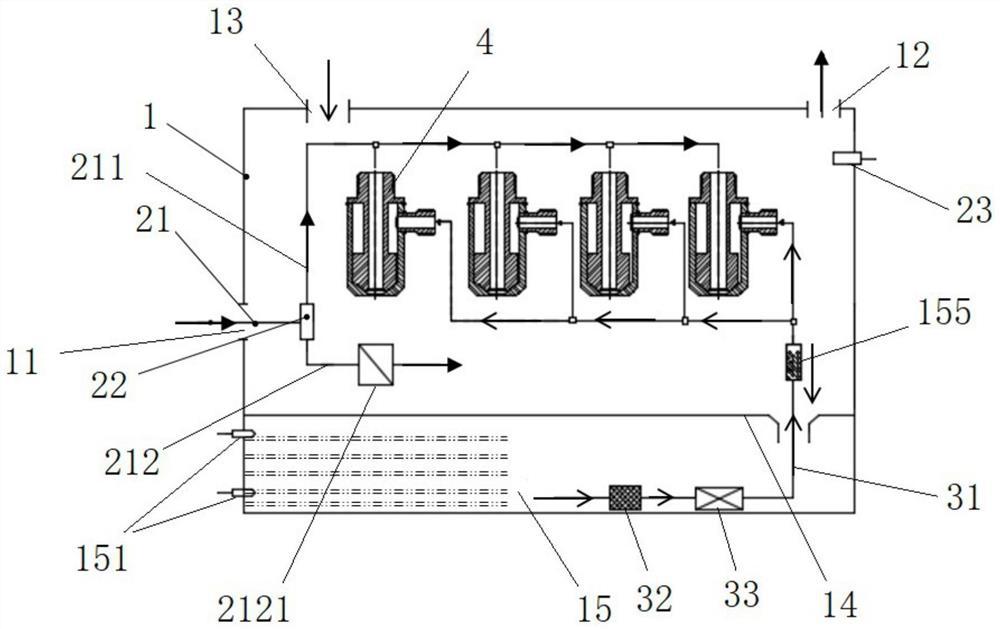

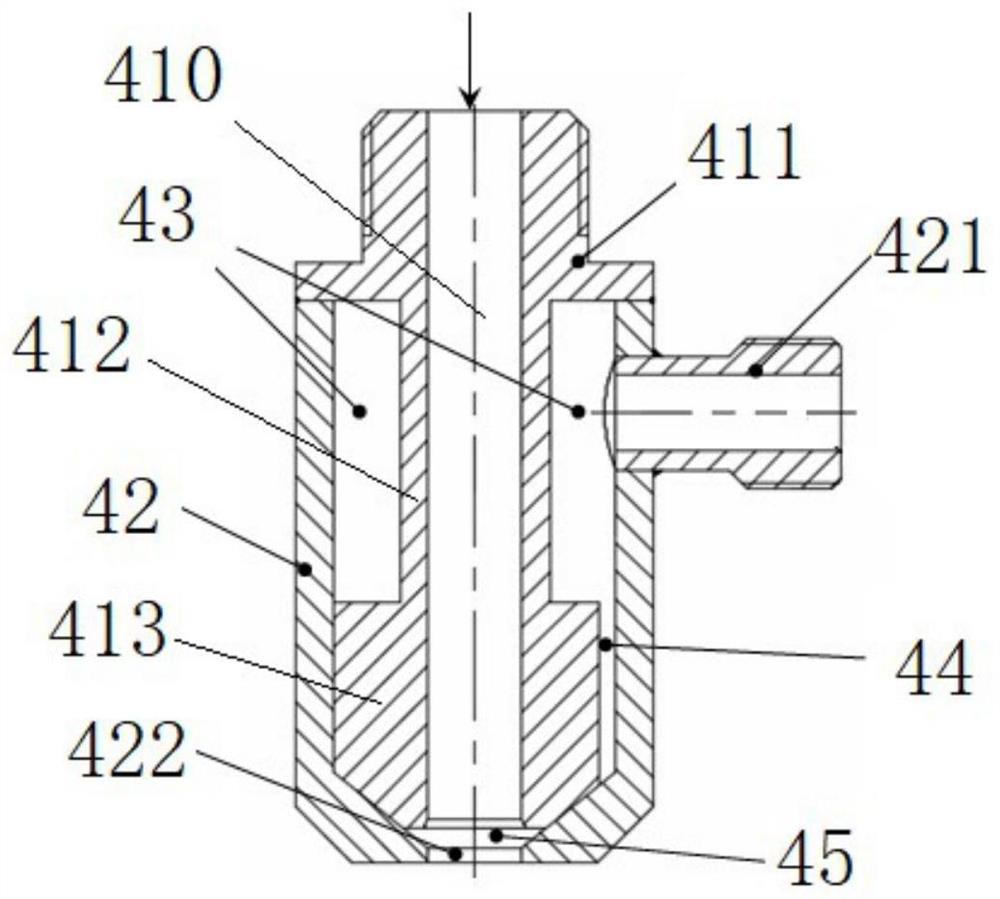

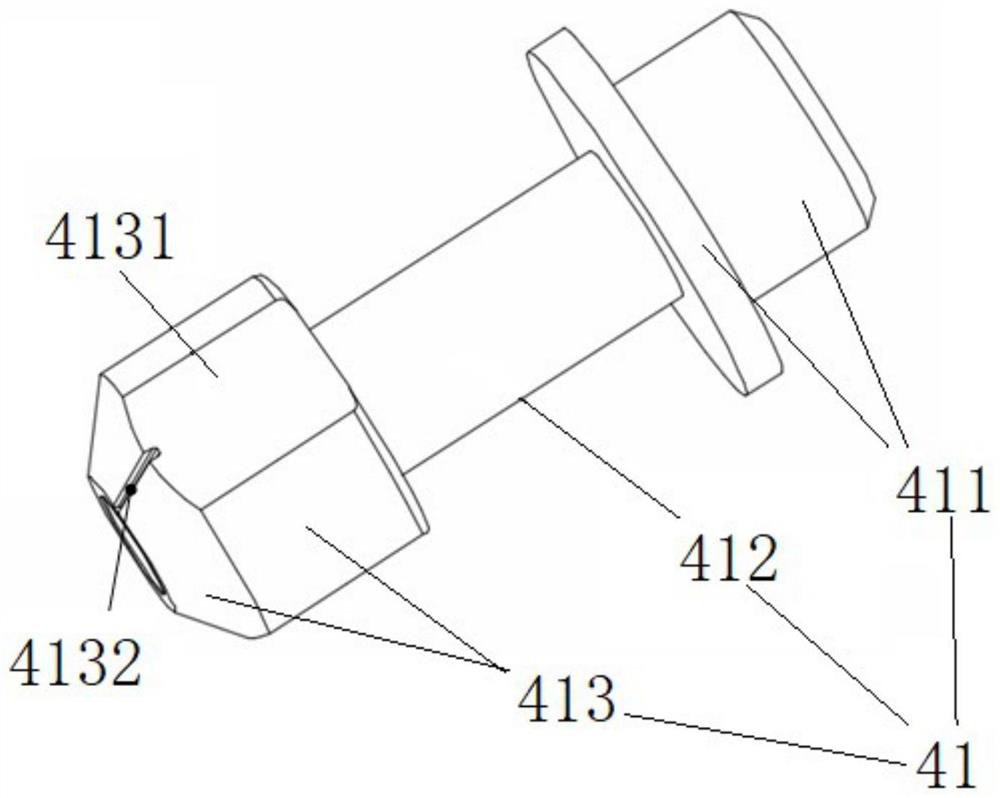

[0043] On the one hand, if figure 1 As shown, this embodiment provides a fuel cell humidification system, wherein the fuel cell humidification system includes: a tank 1 , a dual-fluid injector 4 , and a compressed gas pipeline. Wherein, the dual-fluid injector 4 is installed in the box body 1; and the dual-fluid injector 4 has an air inlet and a water inlet; wherein, the dual-fluid injector 4 is used for mixing the incoming water and the incoming air and injecting it into the casing 1 Inside. The compressed gas pipeline includes an air intake pipe 21, a first branch pipe 212, and a second branch pipe 211; wherein, the air intake pipe 21 is installed at the compressed gas inlet 11 of the casing 1; 212 communicates with the second branch pipe 211 ; wherein, the first branch pipe 212 is used to transport the compressed gas into the tank 1 ; the second branch pipe 211 communicates with the air inlet of the dual-fluid injector 4 . Wherein, the first branch pipe 212 or the second ...

Embodiment 2

[0048] Preferably, this embodiment provides a fuel cell humidification system, compared with the previous embodiment, such as figure 1 As shown, the present embodiment is further designed as follows:

[0049] A humidity sensor 23 is installed in the box body 1 for real-time detection of the humidity of the compressed gas in the box body 1; wherein the humidity sensor 23 is used for connecting the control system to feed back the real-time humidity detection value of the compressed gas in the box body 1 to Control system; the control system issues instructions according to the real-time humidity detection value, controls the gas flow regulating device 2121, and adjusts the compressed gas flow flowing from the intake pipe 21 to the first branch pipe 212 and the second branch pipe 211.

[0050] Preferably, the control system is a fuel cell ECU.

[0051] Specifically, when the real-time humidity detection value of the compressed gas in the box 1 is lower than the set requirement, ...

Embodiment 3

[0057] Preferably, this embodiment provides a fuel cell humidification system, compared with the above embodiments, such as figure 1 As shown, the present embodiment is further designed as follows:

[0058] A water storage space 15 is provided in the box body 1 of this embodiment; wherein, the water inlet of the dual-fluid injector 4 communicates with the water storage space 15 through a water inlet pipeline 31; a water injection port 13 is also provided on the box body 1 to pass through The water injection port 13 injects water into the water storage space 15 .

[0059] Preferably, a partition 14 is arranged inside the tank 1 ; wherein, the partition 14 divides the tank 1 into an upper space and a lower space; wherein, the lower space is a water storage space 15 . Wherein, the dual-fluid injector 4 and the compressed gas pipeline are located in the upper space of the box body 1; wherein, a water inlet hole is opened on the partition plate 14; preferably, the water injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com