Flying dust suppression device for construction site

A suppression device and construction site technology, applied in the separation method, use of liquid separation agent, separation of dispersed particles, etc., can solve the problems of tower crane operation impact, dust easy to spread, tower arm load increase, etc., to increase the coverage , expand the dust suppression area, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

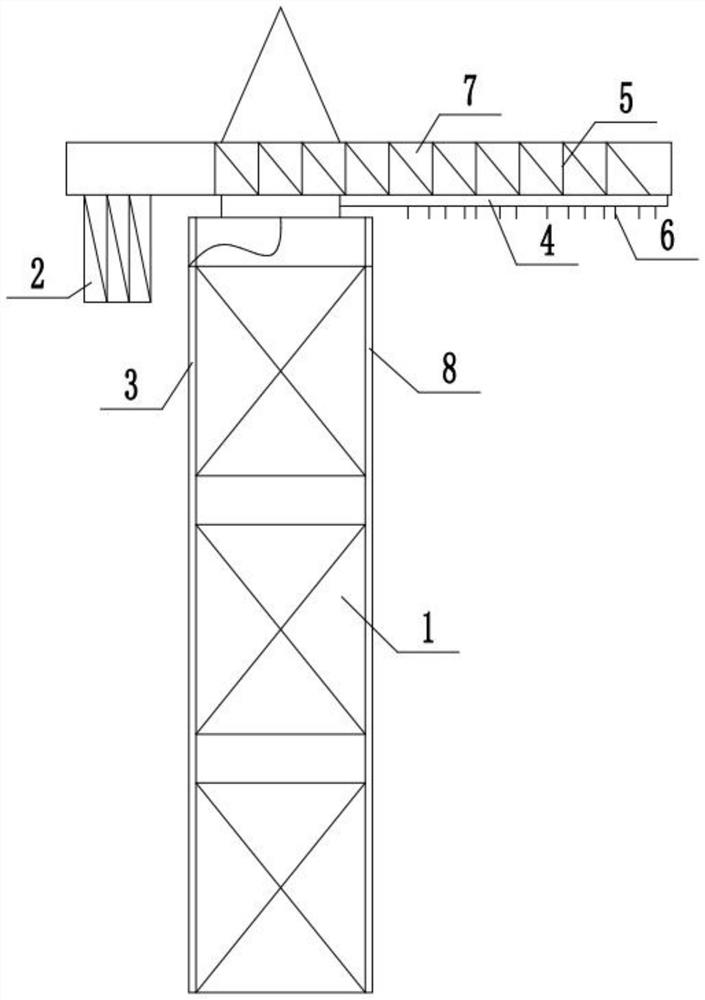

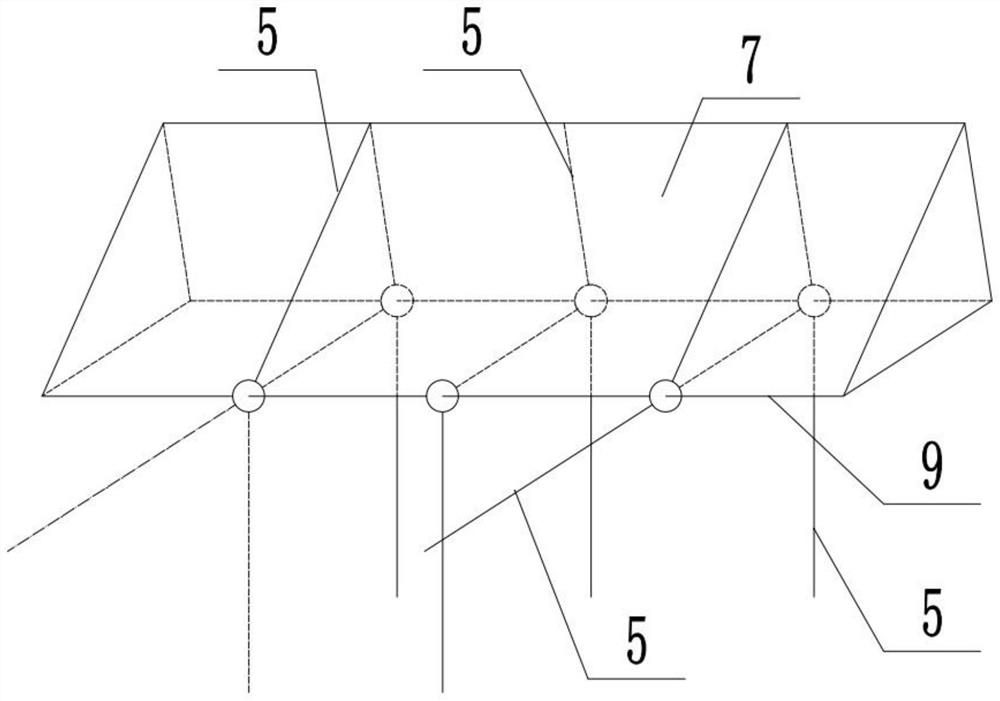

[0029] In a typical embodiment of the present invention, such as Figure 1-Figure 2 As shown, a construction site dust suppression device is given.

[0030] In view of the inconvenient layout of the water supply pipeline 3 of the spray dust suppression device carried by the tower crane and the difficulty in meeting the demand in the scope of work, a dust suppression device on the construction site is provided, which uses the tower arm 7 arm pipe 9 and the tower body 1 standard joint column 8 as the transportation The main pipeline of the water flow, combined with the rotating joint, avoids the problem of entanglement and interference caused by the external water pipe hanging on the tower crane; combined with the rotatable expansion tube 5, it can increase the coverage of the spray and can be accommodated on the arm tube 9. During this period, the tower arm 7 is reinforced to increase the strength of the tower arm 7 to meet the needs of normal lifting.

[0031] The dust suppre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com