Waste emulsion explosive treatment method and device

A technology for waste emulsion explosives and treatment methods, which is applied in the field of treatment methods and devices for waste emulsion explosives. It can solve the problems of incomplete bonding of plastic films, large amount of waste emulsion explosives, and no separate treatment of products. Improve the effect of waste drug state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] Before the treatment of the waste emulsion explosives, it is firstly distinguished, one is latex matrix waste medicines and the waste medicines left in the pipeline; the other is the waste medicines produced by the damaged packaging of emulsion explosives. According to the different types of waste drugs, different processes are carried out.

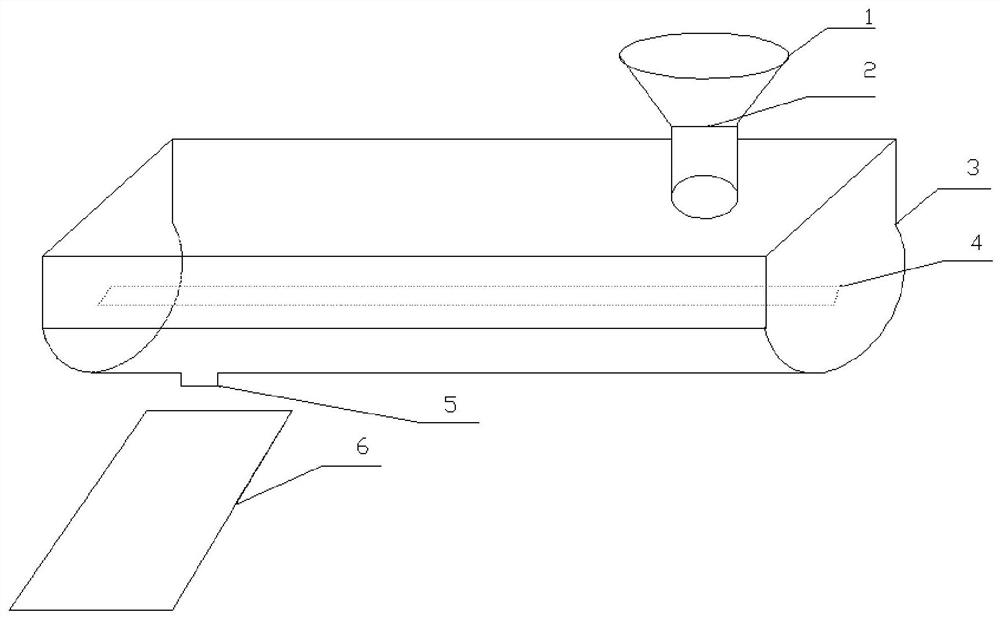

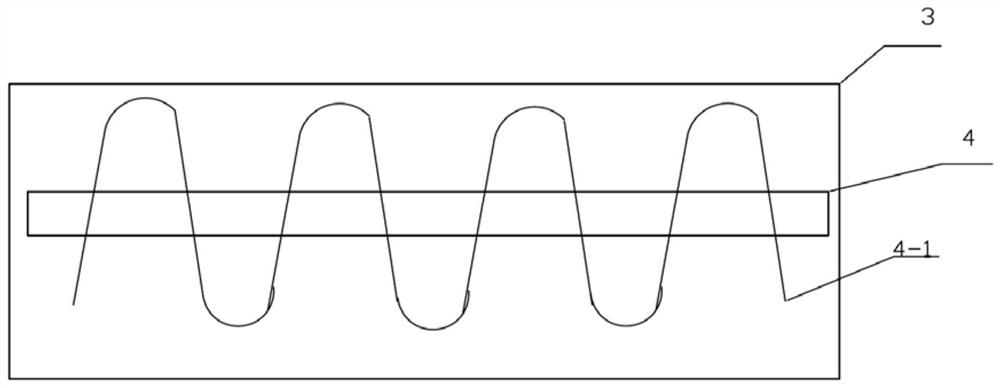

[0029] Latex matrix waste medicine and waste medicine at the beginning and end of the material retained in the pipeline are directly added to the waste medicine treatment device of the present invention. First, the waste medicine is added to the feeding funnel 1. To the material conveying screw device 3, the waste medicine is transported to the discharge port 5 through the material conveying screw 4, and then enters the conveying device 6 from the material discharge port 5, and the conveying device 6 heats the waste medicine at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com