Broaching machine broach structure health monitoring system and method

A health monitoring system and technology for health monitoring, applied in broaching machines, accessories of broaching machines, measuring/indicating equipment, etc., can solve the problems of scrap economy and loss of workpieces and tools, and achieve low equipment cost, simple and reliable structure, Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

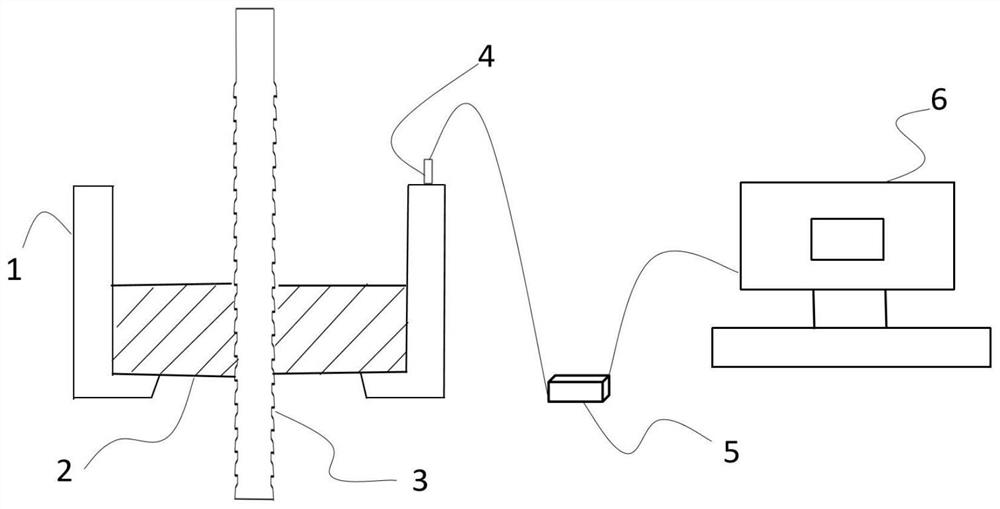

[0031] see figure 1 , a broaching tool structure health monitoring system, comprising a main slide plate 1, a workpiece 2, a broaching tool 3, an acceleration sensor 4, a data acquisition card 5 and a host computer 6, wherein the acceleration sensor 4 is installed on the broaching machine The sliding boards on both sides of the bed are used to measure the acceleration signal in the broaching direction. The acceleration sensor 4 is connected to the data acquisition card 5. The data acquisition card 5 obtains a digital signal and transmits it to the host computer 6. After the host computer 6 intercepts the vibration signal of the sensitive section Quantitative assessment of the structural health of the broach after spectral analysis.

[0032] The structure health monitoring system of the broaching tool of the broaching machine in this embodiment can realize quantitative evaluation and prediction of slight wear or damage of the broaching tool. The invention has the advantages of...

Embodiment 2

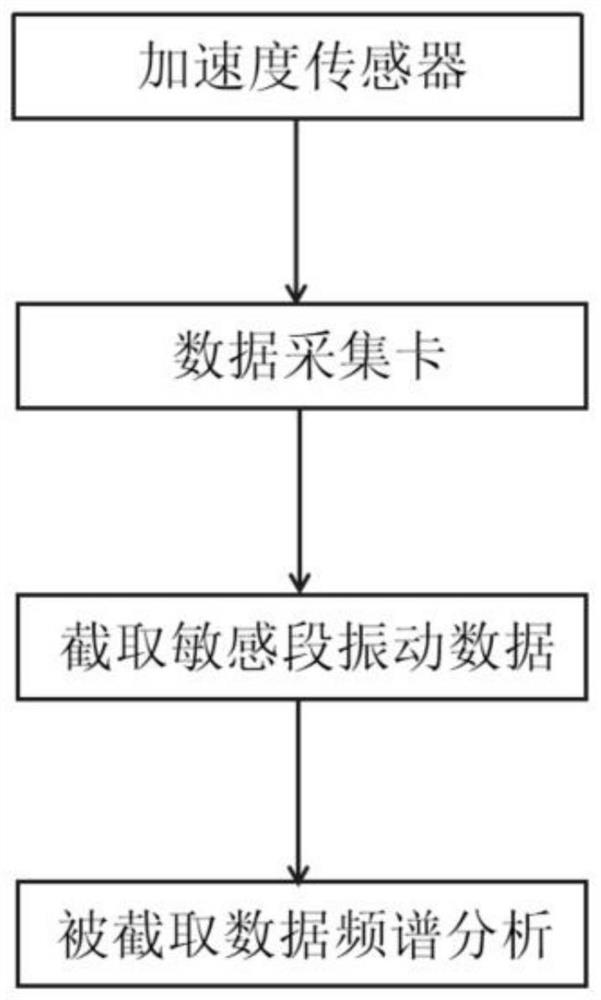

[0034] see figure 2 , a method for monitoring the health of a broaching broach structure, which is operated using a system for monitoring the health of a broaching broach structure in Embodiment 1, wherein the monitoring method includes the following steps:

[0035] ① The broach moves at a constant speed, and its teeth will excite the workpiece;

[0036] ②The wear and damage of the tool will cause the excitation of the tool to the workpiece to increase significantly in a certain period of time—a wear-sensitive period;

[0037] ③ Regardless of whether the excitation is periodic or not, a part of the frequency with a relatively large amplitude will be generated on the spectrogram—the characteristic frequency;

[0038] ④Wearing or damage of the broach will lead to a significant increase in the amplitude of all frequencies of the spectrum signal;

[0039] ⑤ Analyze the characteristic frequency amplitude generated by the cutting excitation of the spectrum signal, and quantitativ...

Embodiment 3

[0042] In this embodiment, a broaching tool structure health monitoring method, the acceleration signal collected by the acceleration sensor can only be used after screening; by observing the time domain signal to determine the time domain sensitivity of broach damage to energy changes segment, the sensitive segment is subjected to fast Fourier transform to obtain a spectrogram that can represent the tool wear and damage signal.

[0043] When intercepting the time-domain sensitive segment, it must be ensured that the length and position of the intercepted data are consistent when the sampling frequency of the acceleration sensor is constant; if the length or position is inconsistent, it means that the characteristic frequency amplitudes of the spectrograms are not comparable.

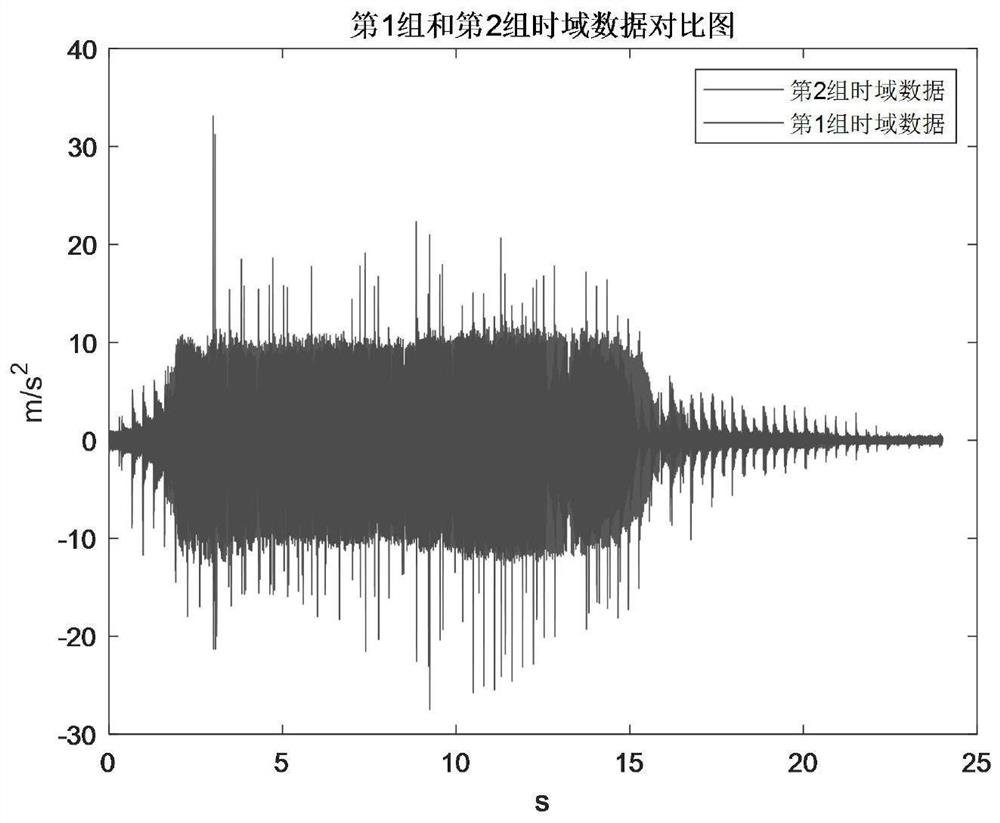

[0044] In this embodiment, the broach broaches the processed workpiece at a constant broaching speed, and the data acquisition card first intercepts the vibration signal of the sensitive section after co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com