A pneumatic multi -way control system and method of a multi -noble biological 3D printing system

A 3D printing, multi-channel control technology, applied in the field of biological 3D printing, to ensure the pressure supply and pressure relief, improve accuracy, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

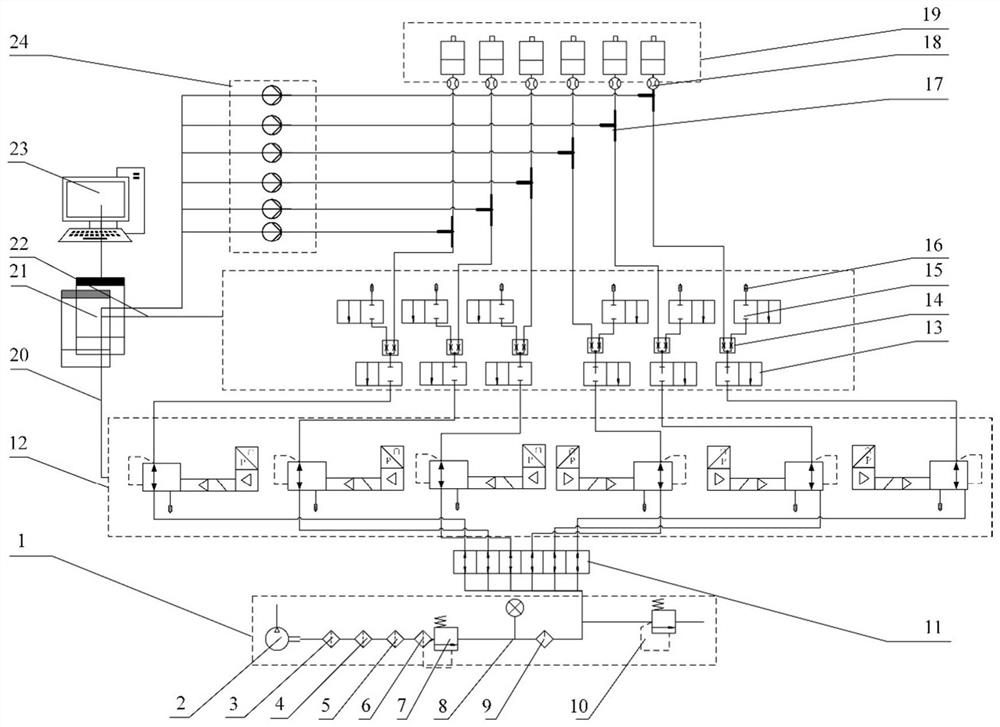

[0028] like figure 1 As shown, the multi-nozzle pneumatic control system of the biological 3D printer of the present invention includes an air source processing module, an air pressure control module, a pressure supply and pressure relief module, an extrusion nozzle and a feedback control module. The number of air paths in this embodiment is 6, and the number of multi-function signal acquisition cards in the feedback control module is two. It should be noted that the number of multi-function signal acquisition cards can be increased to meet the required analog output requirements, which can be 3, 4, etc.

[0029] In the pneumatic multi-channel control system, the compressed gas of the air pump is filtered step by step through 4 filters and dryers with different filter grades to achieve the air source cleanliness and dryness requirements in the biological extrusion printing process. In the embodiment, four filters of different filtration grades are used, namely, a 40-micron fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com