Production method of cold-resistant and anti-freezing rubber floor mat

A production method and floor mat technology, which is applied in the field of floor mats, can solve the problems of poor cold resistance and frost resistance of the floor mats, and the brittleness of the floor mats, and achieve the effects of prolonging the service life, not becoming brittle, and enhancing the wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

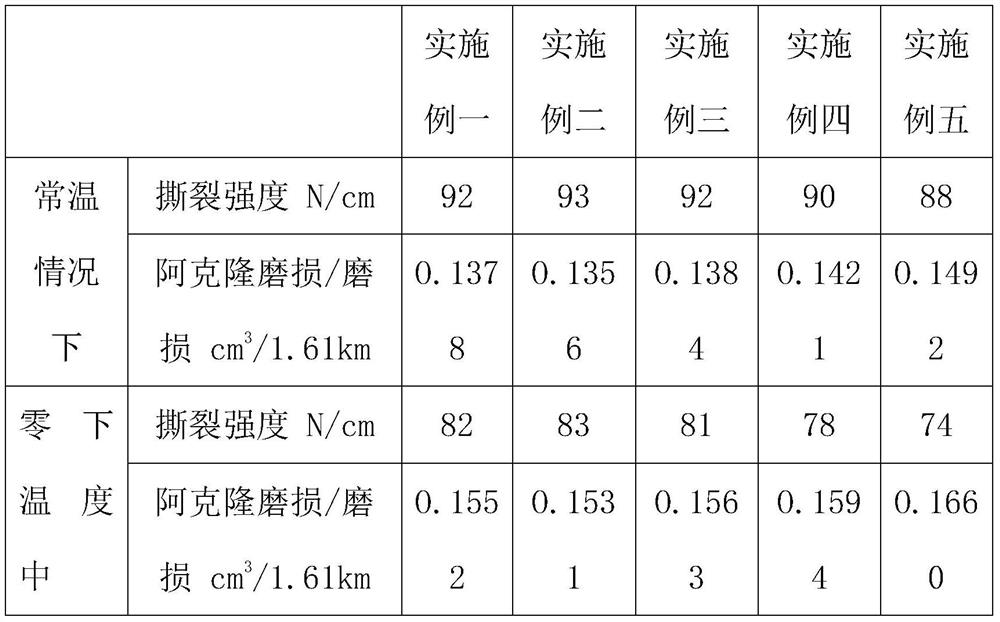

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with specific embodiments.

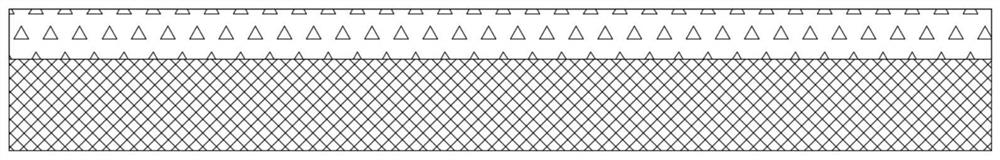

[0025] refer to Figure 1-2 , embodiment one

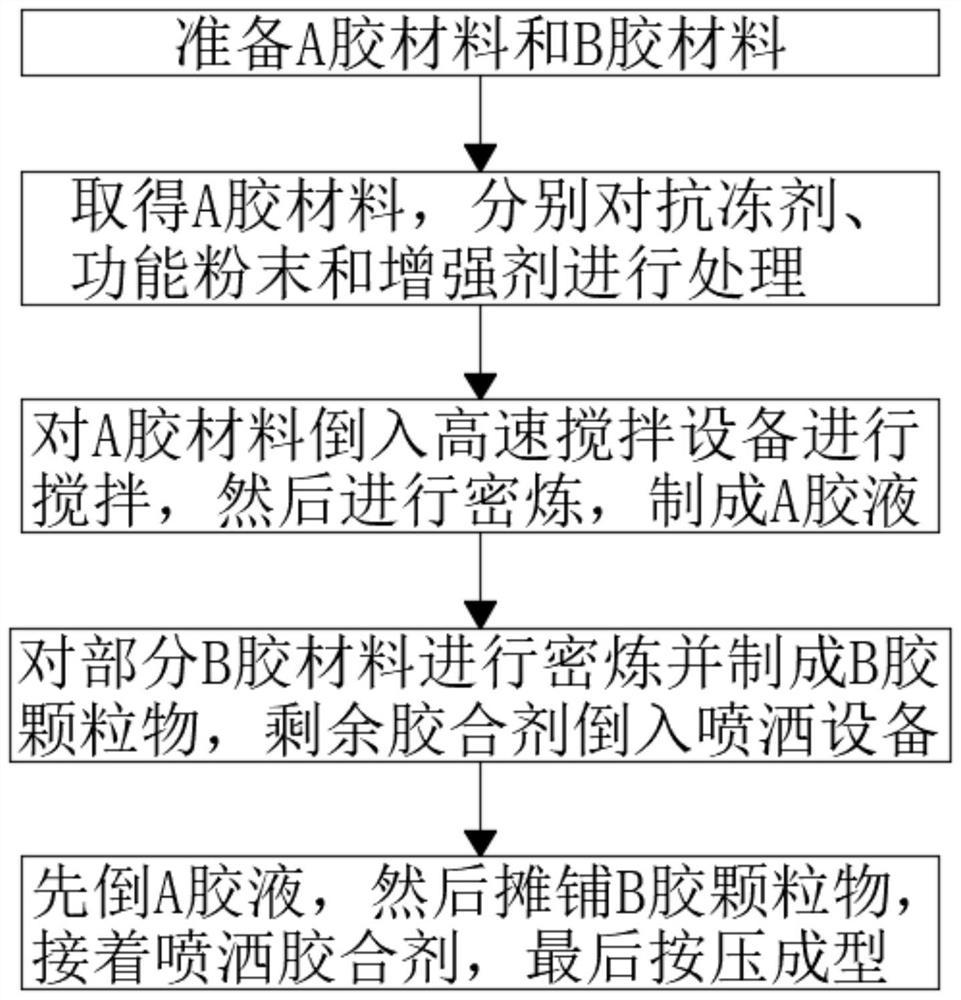

[0026] Propose a kind of production method of cold-resistant frost-resistant rubber floor mat in the present embodiment, comprise the following steps:

[0027] S1: Prepare A and B rubber materials. A rubber material includes 100 parts of main rubber, 155 parts of filler, 16 parts of rubber oil, 9 parts of antifreeze, 19 parts of functional powder, and 44 parts of reinforcement agent and 40 parts of adhesive, B rubber material includes 100 parts of rubber powder, 155 parts of filler, 16 parts of rubber oil, 9 parts of antifreeze, 19 parts of functional powder, 44 parts of reinforcing agent and 58 parts The antifreeze agent contains hydroxy silicone oil, paraffin, polyoxypropylene glyceryl ether, dimethyl sulfoxide and ether, the functional powder contains zinc oxide, sulfur and metal salts, and the reinforcing agent contains s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com