Adjustable turnover formwork at concrete floor slab construction joint

A technology for construction joints and concrete, which is applied in the direction of formwork/formwork components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., which can solve the problems of poor concrete forming effect, difficult process, and cumbersome process and other problems to achieve the effect of improving the performance of anti-leakage slurry, shortening the construction period and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

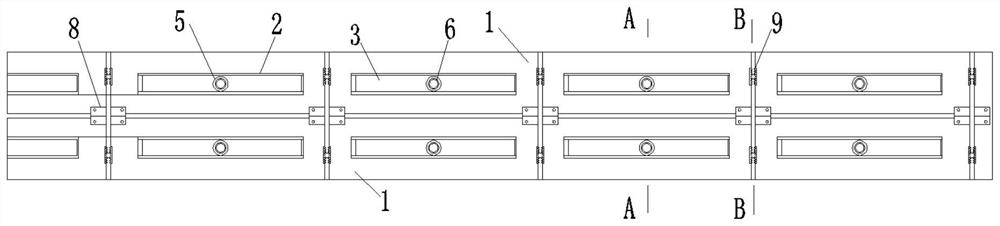

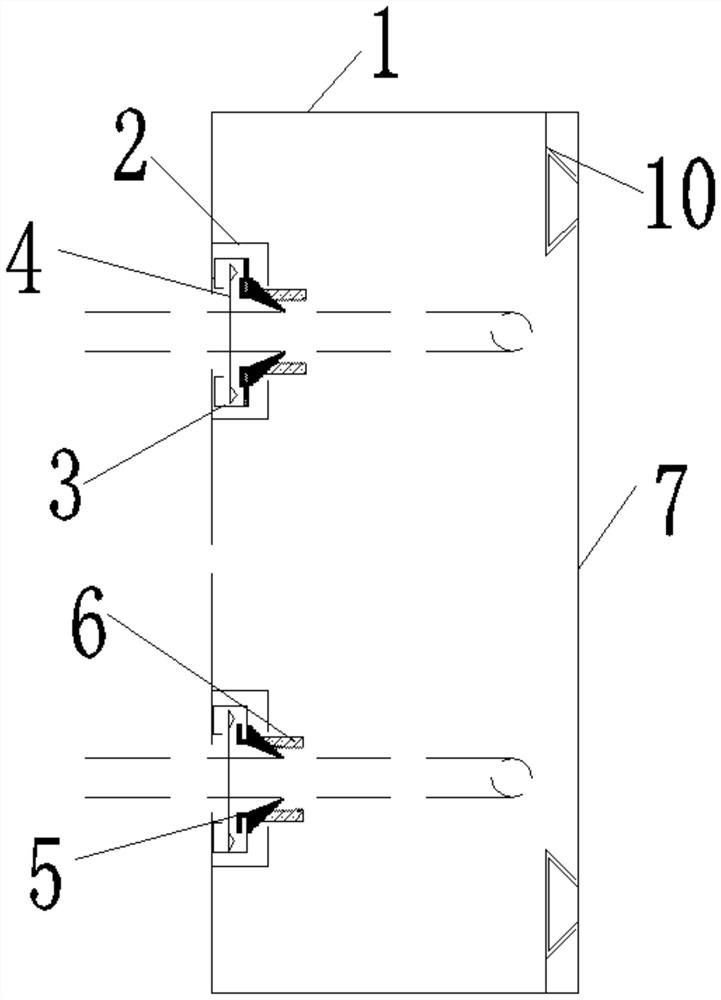

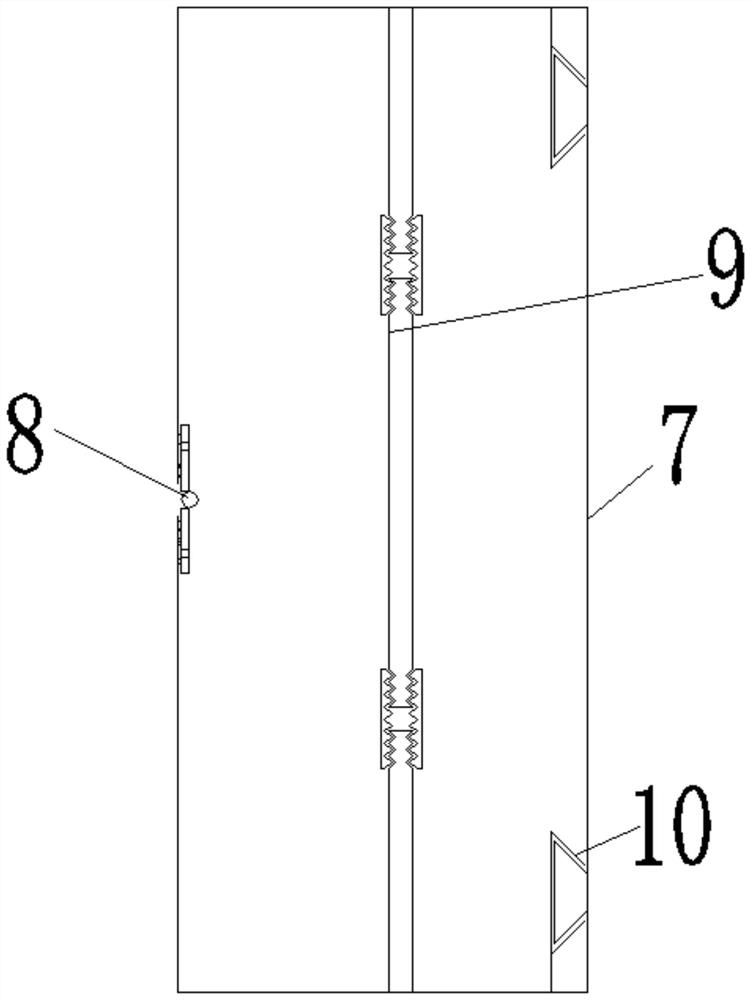

[0026] Embodiment 1: An adjustable turnover formwork at the construction joint of a concrete floor, including two groups of anti-leakage slurry steel formwork 1 arranged mirror-symmetrically along the horizontal direction. The vertical panels of the slurry steel formwork 1 are hinged by hinges 8, and the adjacent sides of the upper and lower leak-proof slurry steel formworks 1 are provided with leak-proof slurry strips to block the gap between the two leak-proof slurry steel formworks 1. Leakage, the horizontal panels of the two sets of leak-proof slurry steel formwork 1 are connected as a whole through the connecting sealing plate 7, the connecting sealing plate 7 is arranged on the back side of the hinge 8, and there are several equal distances on the vertical panel of the leak-proof slurry steel formwork 1. The strip-shaped opening, the leak-proof slurry steel template 1 is fixed with a profiled steel plate groove 2 at the position corresponding to the strip-shaped opening, ...

Embodiment 2

[0036] Embodiment 2: In Embodiment 1, there is also the problem that the gap between the rubber telescopic buckle 5 and the ribs may leak. Therefore, on the basis of Embodiment 1, this embodiment also includes: the rubber telescopic buckle 5 extends into the leak-proof One side of the slurry steel formwork 1 is provided with threads, and the rubber telescoping buckle 5 is connected with the anti-leakage slurry nut 6 by threads. After the steel bar is inserted into the formwork through the rubber telescopic buckle 5, turn the anti-leakage slurry nut 6 to move the anti-leakage slurry nut 6 to the direction of the anti-leakage slurry steel formwork 1, thereby driving the rubber telescopic buckle 5 to squeeze in the direction of inserting the bar and sealing the rubber The gap between the telescopic buckle 5 and the inserted rib ensures the anti-leakage slurry effect of the device. The adjustable range of the rubber telescopic buckle 5 is 6-30mm.

[0037] When installing this dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com