Gas oven temperature control system, gas oven and temperature control method thereof

A temperature control system and gas technology, applied in the combustion method, gas fuel burner, roaster/barbecue grid, etc., can solve the problems of low control accuracy and short use time, and achieve high temperature control accuracy, flexible use, Action-reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

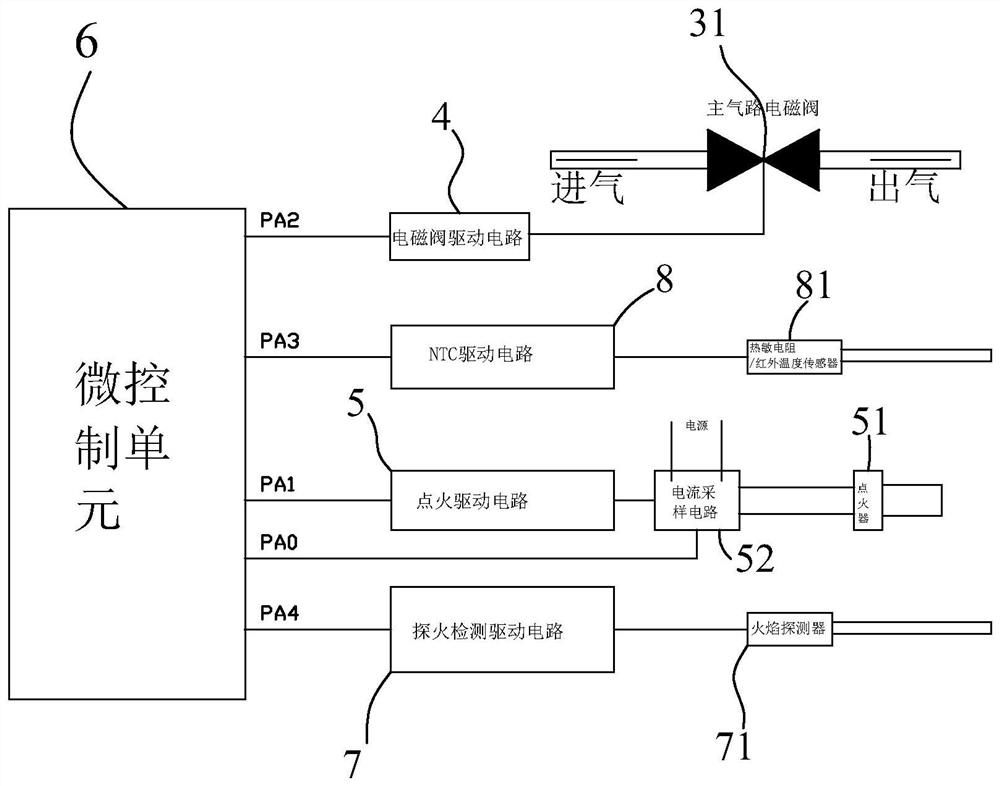

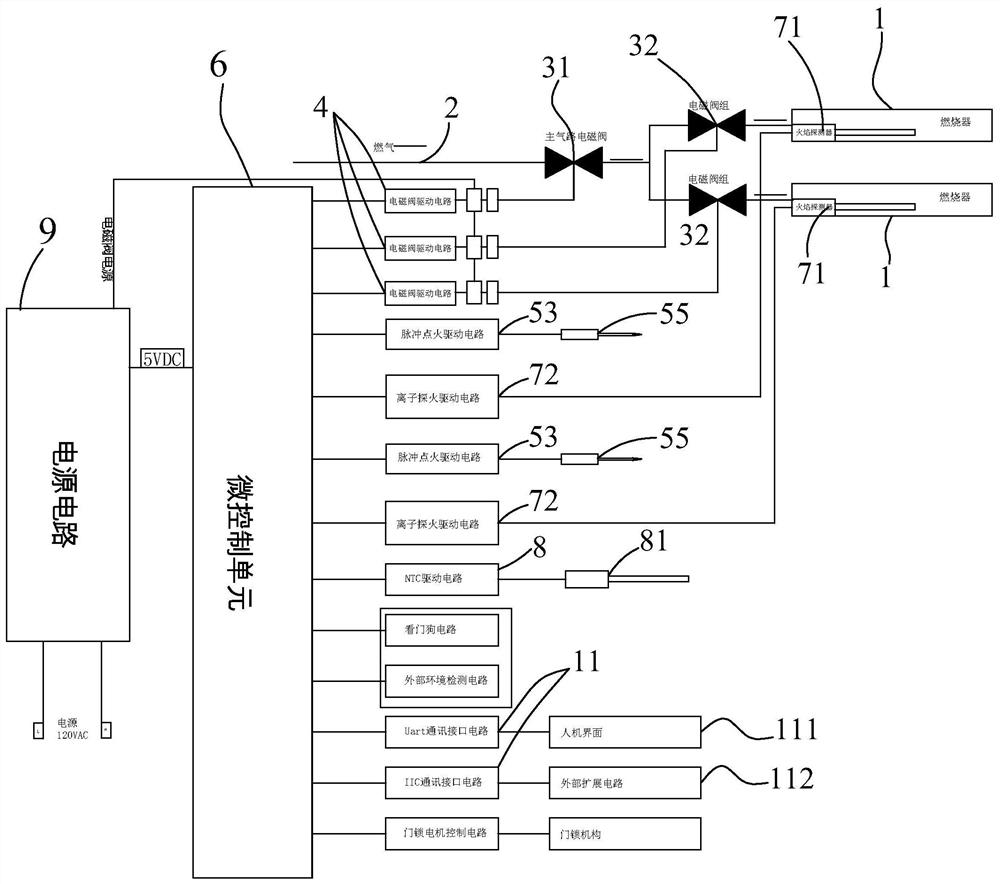

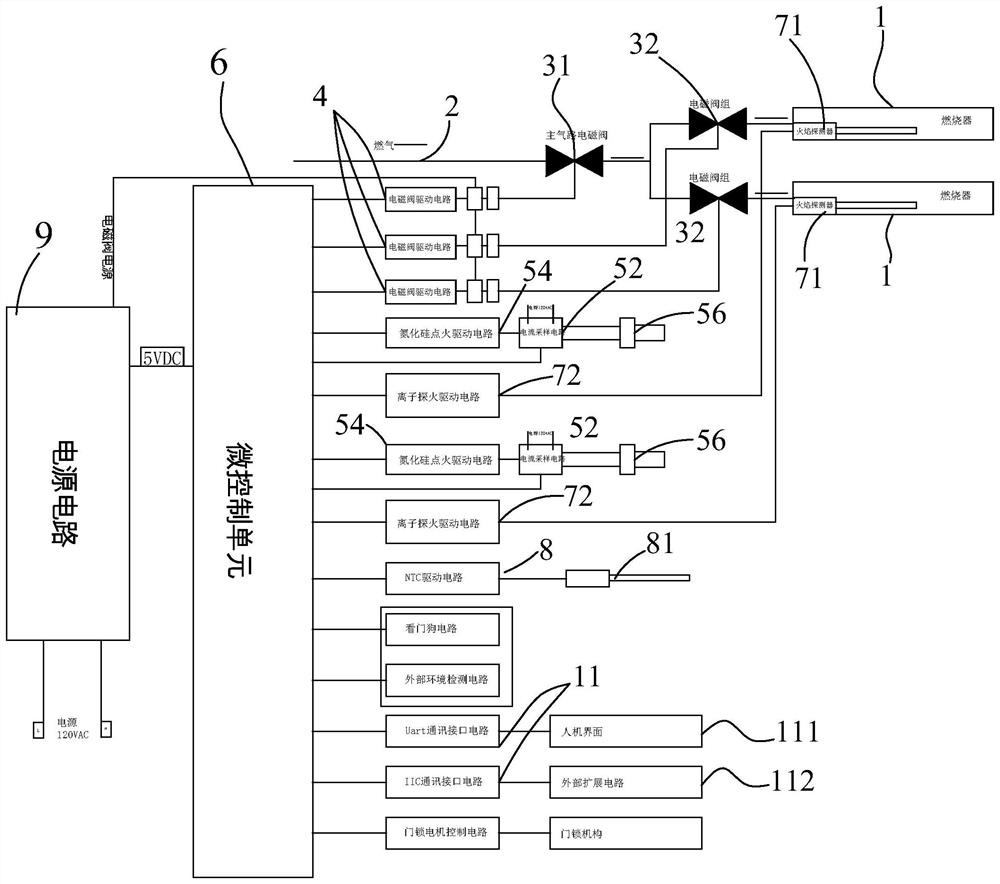

[0028] refer to Figure 1 to Figure 3 Shown, a gas oven temperature control system, including

[0029] The burner 1 is connected with the main gas circuit 2 and the main gas circuit solenoid valve 31 for switching the main gas circuit 2;

[0030] Solenoid valve driving circuit 4 is electrically connected with the main gas path solenoid valve 31 to drive the opening and closing of the main gas path solenoid valve 31;

[0031] The ignition driving circuit 5 is connected with an igniter 51 for igniting the burner 1, and the ignition driving circuit 5 drives the igniter 51 to heat up and ignite;

[0032] The micro-control unit 6 drives the ignition drive circuit 5 to work and obtains the data of the energizing current and the energization time of the igniter 51 through the current sampling circuit 52. The micro-control unit 6 outputs a control si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com