Circuit board with buffer layer and heat conduction admixtures

A buffer layer, circuit board technology, applied in circuit thermal devices, printed circuit components, printed circuit stress/deformation reduction, etc., can solve problems such as poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

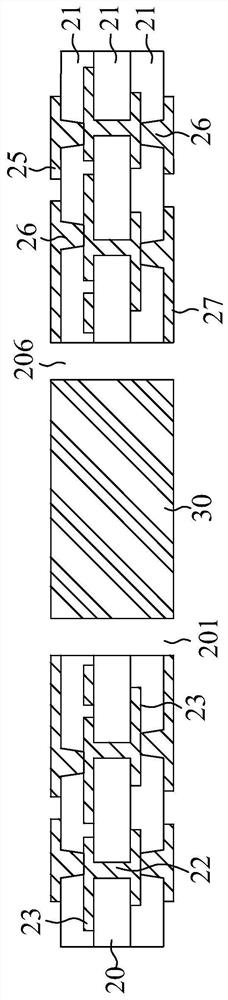

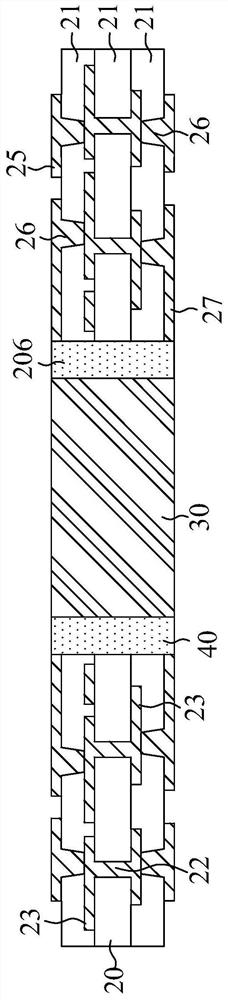

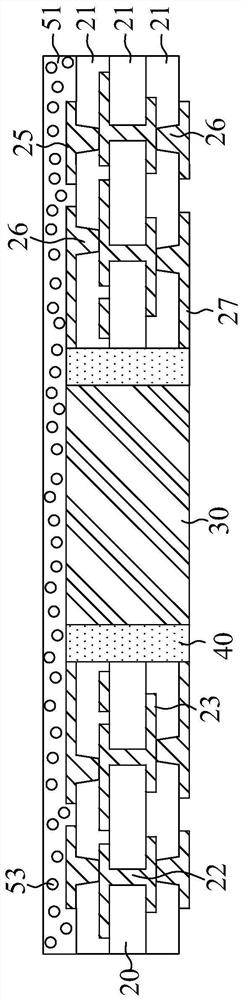

[0020] Figure 1-5 In the first embodiment of the present invention, a diagram of a manufacturing method of a circuit board includes an interconnect base, a thermoelectric conductor, a bonding layer, a top buffer layer, a thermally conductive additive, and a top routing layer.

[0021] figure 1 It is a sectional view of inserting the thermoelectric conductor 30 into the opening 201 of the interconnection base 20 . The opening 201 of the interconnect base 20 extends from the top surface to the bottom surface, which can be formed by various techniques, such as punching, drilling or laser cutting. The inner sidewall of the opening 201 of the interconnect base 20 laterally surrounds the peripheral sidewall of the thermoelectric conductor 30 and is spaced apart from the peripheral sidewall of the thermoelectric conductor 30 . Therefore, the gap 206 is located in the opening 201 between the inner sidewall of the interconnection base 20 and the peripheral sidewall of the thermoelec...

no. 2 example

[0029] Figure 6 It is a sectional view of the circuit board of the second embodiment of the present invention.

[0030] For the purpose of brief description, any descriptions in the above first embodiment that can be used in the same way are incorporated here, and the same descriptions do not need to be repeated.

[0031] The circuit board 200 is similar to Figure 5 The structure shown is different in that the top buffer layer 51 further contains a reinforcing admixture 55 , which is mixed with the thermally conductive admixture 53 in the top buffer layer 51 to improve the reliability of the top buffer layer 51 . More specifically, the reinforcing admixture 55 is preferably a fibrous inorganic material with a higher elastic modulus than the top buffer layer 51, for example, the elastic modulus of the reinforcing admixture 55 may be higher than the elastic modulus of the top buffer layer 51 At least about 10 GPa. Accordingly, the combination of the top cushioning layer 51 ...

no. 3 example

[0033] Figure 7 It is a sectional view of the circuit board of the third embodiment of the present invention.

[0034] For the purpose of brief description, any descriptions in the above-mentioned first embodiment and second embodiment that can be used in the same way are incorporated here, and it is not necessary to repeat the same descriptions.

[0035] The circuit board 300 is similar to Figure 5 The structure shown is different in that it further includes a bottom buffer layer 52 and a bottom routing layer 62 . The bottom buffer layer 52 laterally extends from the bottom surface of the thermoelectric conductor 30 to the bottom surface of the interconnection base 20 to cover the interconnection base 20 , the thermoelectric conductor 30 and the bonding layer 40 from below. Similar to the top buffer layer 51, the elastic modulus of the bottom buffer layer 52 is lower than the elastic modulus of the thermoelectric conductor 30, for example, the elastic modulus of the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com