Hydrogenation reaction method for isododecane production

A technology for isomerization of dodecane and hydrogenation reaction, which is applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, hydrogenation hydrocarbon production, etc., can solve the problem that materials cannot react quickly and uniformly, and reduce production Efficiency and quality and other issues, to achieve the effect of improving service life, improving quality and efficiency, and facilitating use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] In the specific implementation process, such as figure 1 As shown, a hydrogenation reaction method for the production of isomerized dodecane is used in conjunction with a high-efficiency hydrogenation reactor, and the method comprises the following steps:

[0034] 1), isobutene trimer (TIB, trimeric isobutene) reacts with hydrogen in an efficient hydrogenation reactor to prepare isododecane;

[0035] 2) The crude isododecane at the outlet of the efficient hydrogenation reactor is dehydrated and dried, then enters the first-level deodorization adsorption tower, and then enters the protection deodorization tower to obtain the finished isododecane;

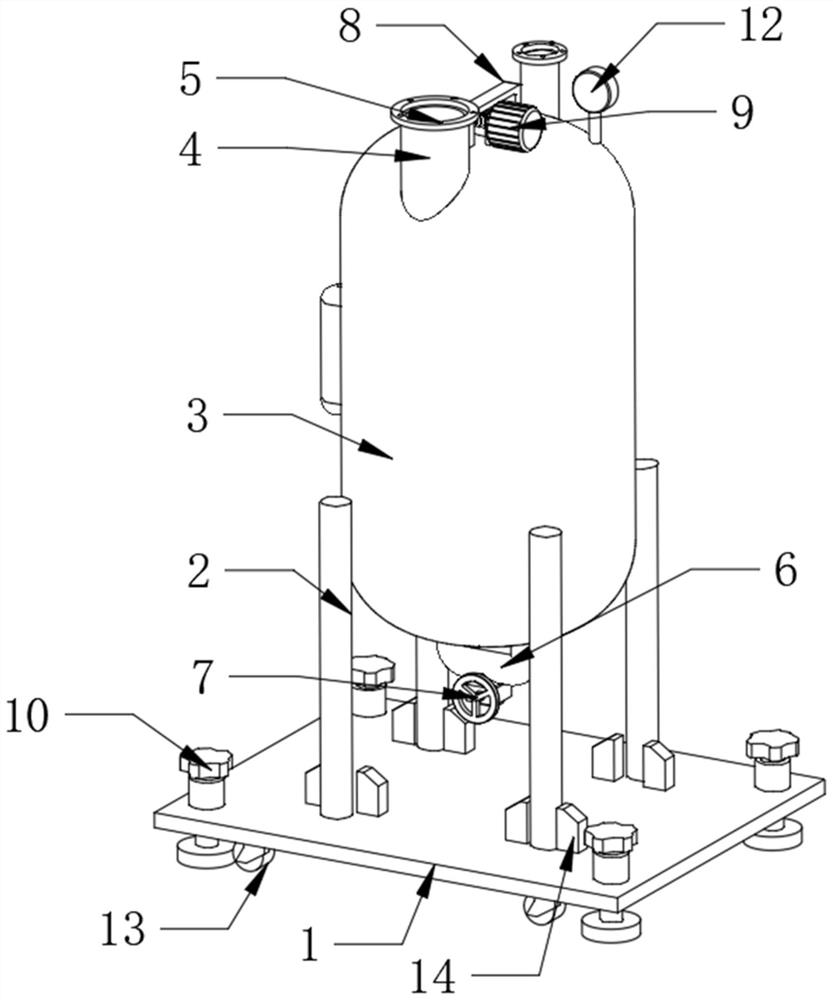

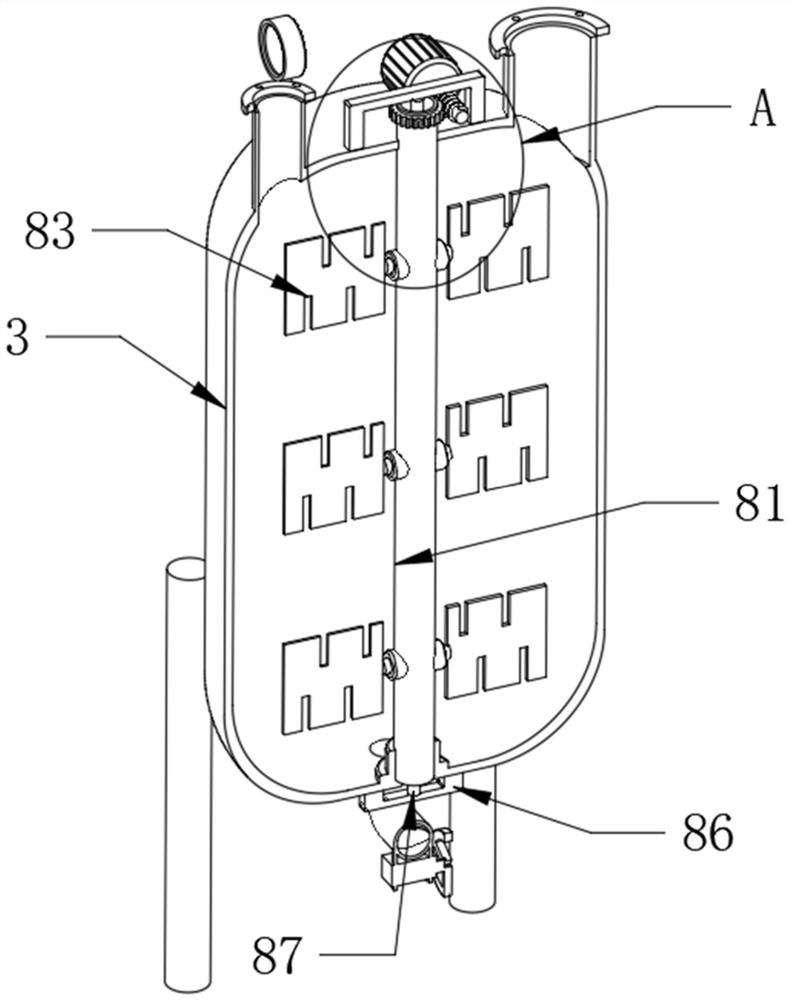

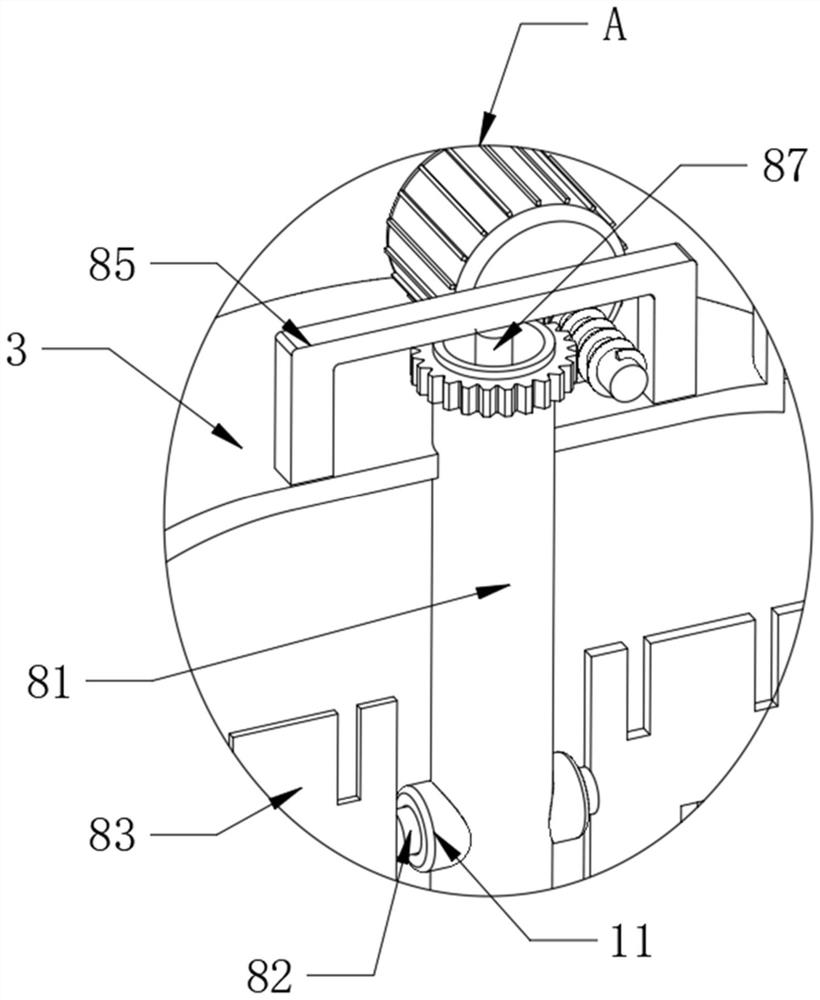

[0036] Wherein the efficient hydrogenation reactor described in step 1) comprises a mobile platform 1, a support column 2 and a reactor body 3, the middle part of the upper surface of the mobile platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com