Preparation method of porcelain tile with special micro-diamond particle distribution effect

A technology of porcelain tiles and particles, which is applied in the field of tile production, can solve the problems of high stone prices and the inability to be popularized by ordinary consumer groups, and achieve the effects of reducing product prices, improving three-dimensionality and simulation, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

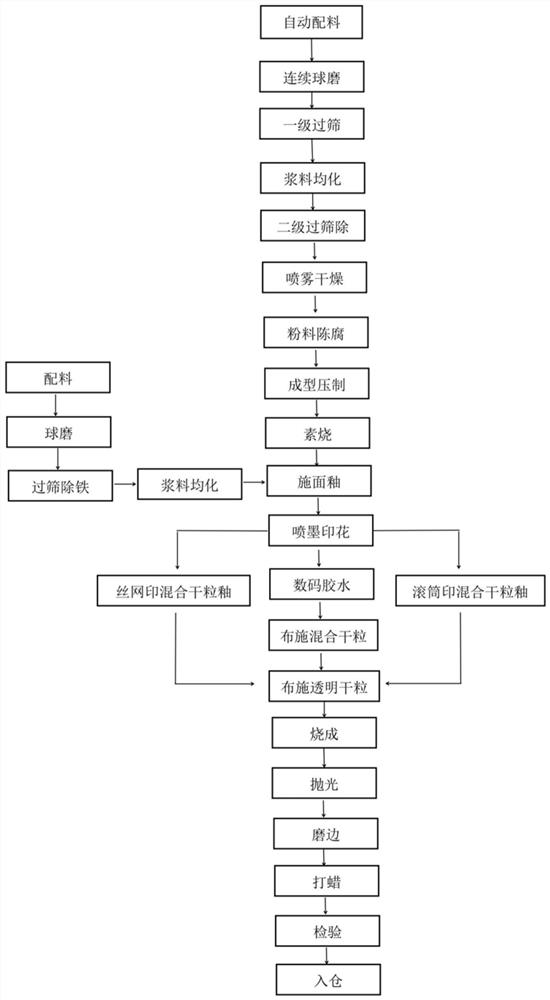

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a ceramic tile with a special effect of distributing micro-drilling particles, comprising the following steps:

[0025] Step (1) select the corresponding proportion of the raw materials for the green body for batching, finely crush it into a slurry with a fineness of 10,000-hole sieve through continuous ball milling, and spray-dry the slurry through iron removal. Pressed into a green ceramic tile, and then dried at 190 ° C to obtain a green embryo;

[0026] Step (2) applying surface glaze on the porcelain tile body in step 1;

[0027] Step (3) inkjet printing a color pattern on the surface glaze in step 2, and printing the engraving ink according to the preset texture effect after the pattern is printed, wherein the engraving ink includes the following components by mass percentage: V2O523.5%, Bi2O3 55.2%, Ba2CO3 7.5%, ZnO 4.2%, SiO2 3.4%, Al2O3 3.7%, (K2O+Na2O) 2.7%;

[0028] Step (4) On the pattern layer in step 3, use inkjet printer digital p...

Embodiment 2

[0034] A method for preparing a ceramic tile with a special effect of distributing micro-drilling particles, comprising the following steps:

[0035] Step (1) select the corresponding proportion of the raw materials for the green body for batching, finely crush it into a slurry with a fineness of 10,000-hole sieve through continuous ball milling, and spray-dry the slurry through iron removal. Pressed into a green ceramic tile, and then dried at 210 ° C to obtain a green embryo;

[0036] Step (2) applying surface glaze on the porcelain tile body in step 1;

[0037] Step (3) inkjet printing a color pattern on the surface glaze in step 2, and printing the engraving ink according to the preset texture effect after the pattern is printed, wherein the engraving ink includes the following components by mass percentage: V2O523.5%, Bi2O3 55.2%, Ba2CO3 7.5%, ZnO 4.2%, SiO2 3.4%, Al2O3 3.7%, (K2O+Na2O) 2.7%;

[0038] Step (4) On the concave-convex pattern layer in step 3, screen printi...

Embodiment 3

[0043] A method for preparing a ceramic tile with a special effect of distributing micro-drilling particles, comprising the following steps:

[0044] Step (1) select the corresponding proportion of the raw materials for the green body for batching, finely crush it into a slurry with a fineness of 10,000-hole sieve through continuous ball milling, and spray-dry the slurry through iron removal. Pressed into a green ceramic tile, and then dried at 230°C to obtain a green embryo;

[0045] Step (2) applying surface glaze on the porcelain tile body in step 1;

[0046] Step (3) inkjet printing a color pattern on the surface glaze in step 2, and printing the engraving ink according to the preset texture effect after the pattern is printed, wherein the engraving ink includes the following components by mass percentage: V2O523.5%, Bi2O3 55.2%, Ba2CO3 7.5%, ZnO 4.2%, SiO2 3.4%, Al2O3 3.7%, (K2O+Na2O) 2.7%;

[0047] Step (4) On the pattern layer in step 3, the mixed particles are applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com