Thermoplastic elastomer composition as well as preparation method and application thereof

A thermoplastic elastomer and composition technology, which is applied in the field of thermoplastic elastomer composition and its preparation, can solve the problems of difficult dispersion of carbon black, easy loosening and falling off of adhesive layer, inability to meet the requirements of PP caster rubber coating, etc. Good effect, strong encapsulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

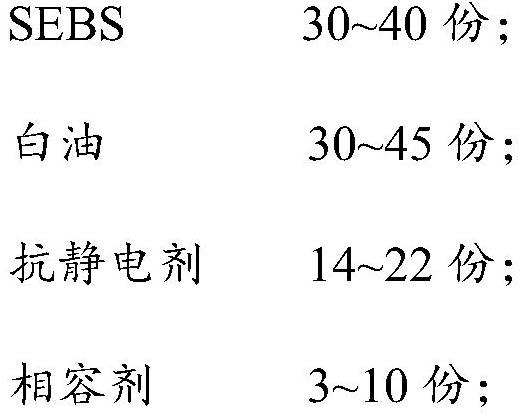

[0054] Embodiments 1-5 provide a series of thermoplastic elastomer compositions, the component contents are shown in Table 1, and the preparation method is as follows:

[0055] S1. First put SEBS and white oil into a high mixer and mix for 3 to 5 minutes to obtain a premix;

[0056] S2. Mix the premix, antistatic agent, compatibilizer and antioxidant in step S1 for 3 to 5 minutes;

[0057] S3. Melt, extrude, cool and granulate the mixture in step S3 in a screw machine. The rotating speed of the screw machine is 300-600 rpm, and the processing temperature is 180-200°C.

[0058] The component content (part) of table 1 embodiment 1~5

[0059] Example 1 Example 2 Example 3 Example 4 Example 5 SEBS 33 33 33 33 33 white oil 43 43 43 43 43 Antistatic agent A 18 — — — — Antistatic agent B — 18 — — — Antistatic agent C — — 18 — — Antistatic agent D — — — 18 — Antistatic agent E — — — — 18 Co...

Embodiment 6~8 and comparative example 1~2

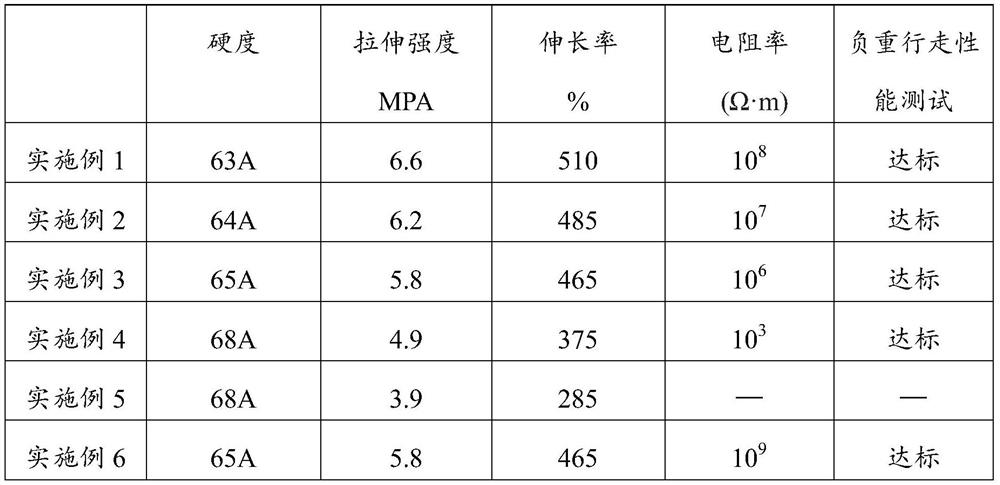

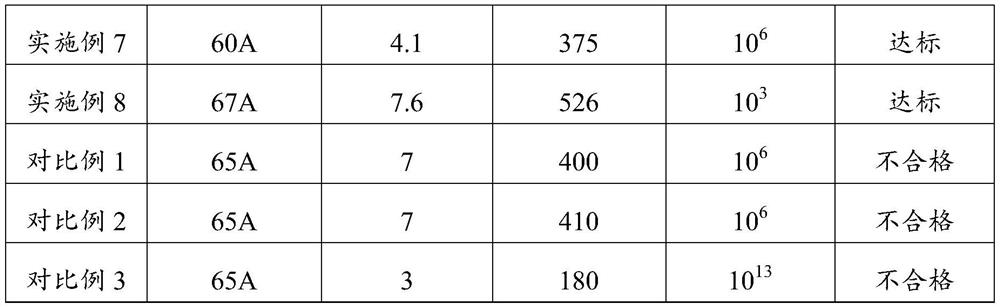

[0061] Examples 6-8 and Comparative Examples 1-2 provide a series of thermoplastic elastomer compositions, the preparation method of which is the same as that of Example 1, and the contents of the components are shown in Table 2.

[0062] Table 2 embodiment 6~8 component content (part)

[0063] Example 6 Example 7 Example 8 Comparative example 1 Comparative example 2 SEBS 33 30 40 33 33 white oil 43 30 45 43 43 Antistatic agent C 18 14 22 — — Antistatic agent F — — — 18 — Antistatic agent G — — — — 18 Compatibilizer A — 10 3 5 5 Compatibilizer B 5 — — — — antioxidant 0.2 0.2 1 0.2 0.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com