Coke oven ascension pipe waste heat recovery device and control method thereof

A waste heat recovery device and heat control technology, used in the heating of coke ovens, furnace safety devices, coke ovens, etc., can solve problems such as tearing of the weld seam of the cylinder, tar condensation, water leakage, etc., to achieve consistent heat exchange efficiency, Less likely, the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0053] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

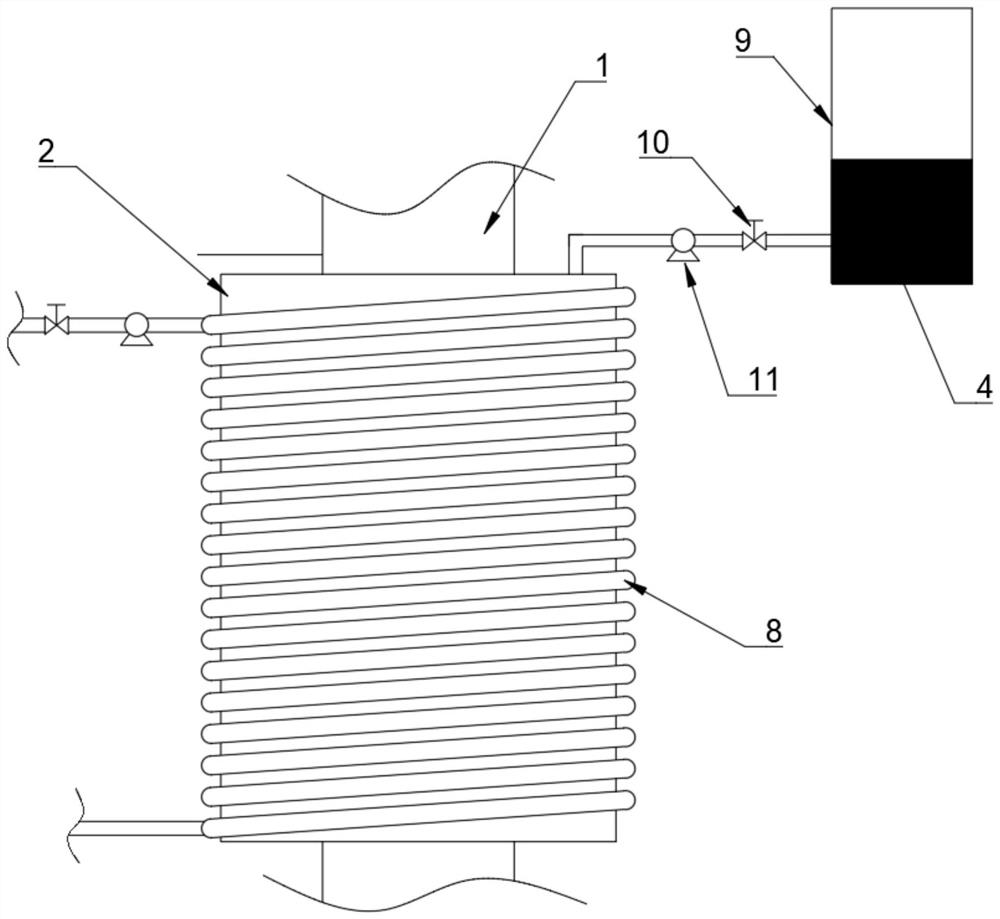

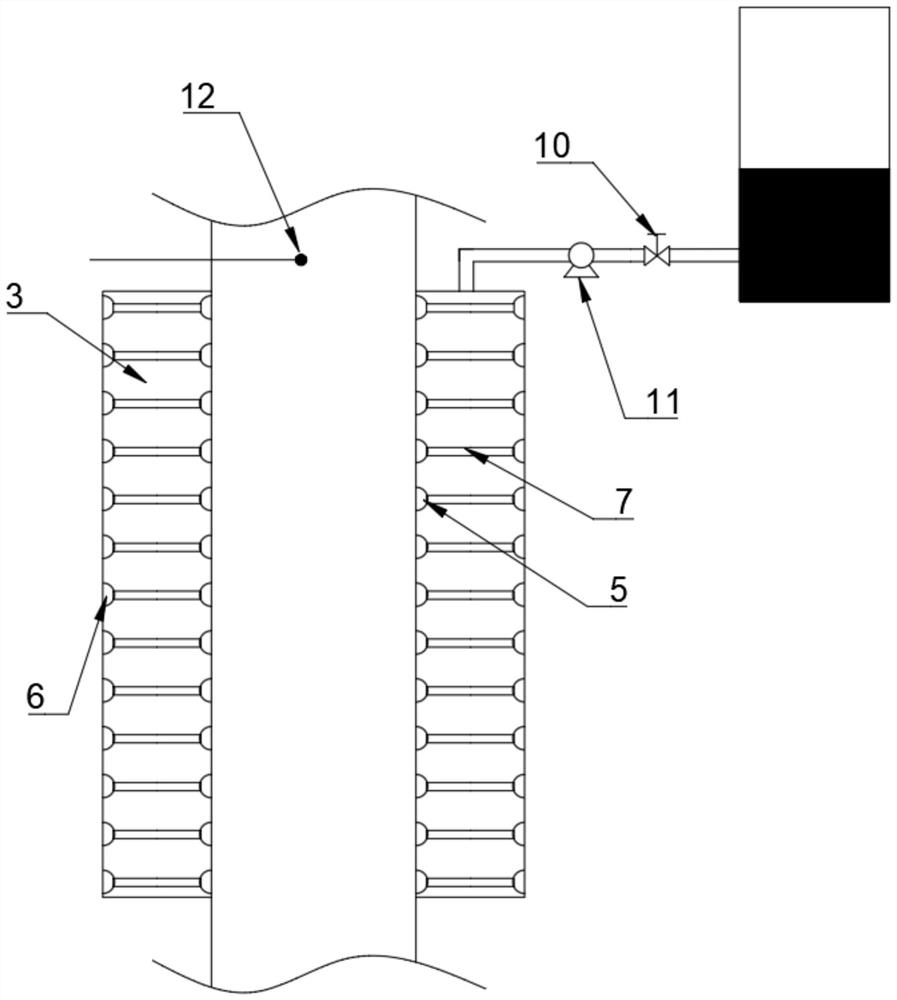

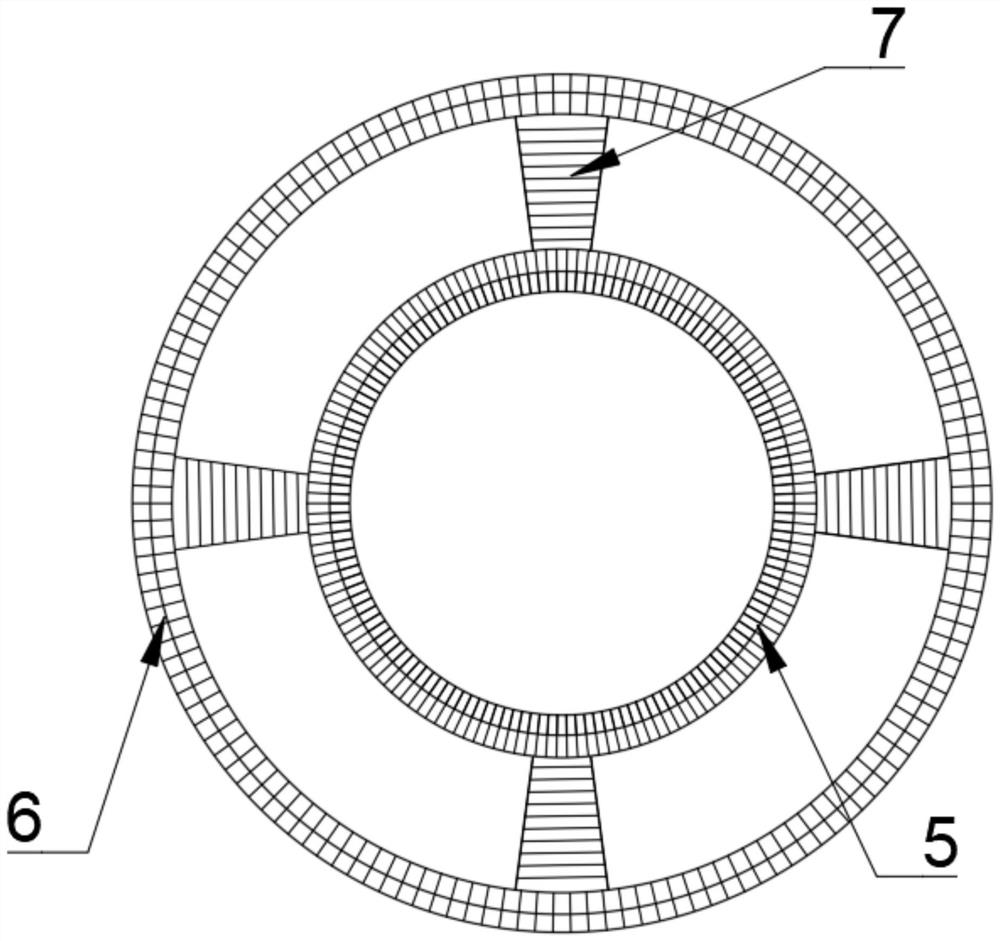

[0054] Such as Figure 1-2 As shown, a coke oven riser 1 waste heat recovery device provided in this embodiment includes a sleeve 2 sleeved outside the riser 1 , and a sealed heat exchange chamber 3 is formed between the sleeve 2 and the riser 1 .

[0055] The heat exchange chamber 3 is filled with a circulating working fluid 4 , and the sleeve 2 is provided with an external heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com