Air inlet channel heat insulation structure on air cylinder cover

A technology of upper intake port and cylinder head, applied in the direction of cylinder head, cylinder, engine components, etc., can solve the problems of large cooling liquid channel design limitations, limited thermal engine state effect, and difficult coating technology, and achieve thermal insulation. Good effect, simple production, roughness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

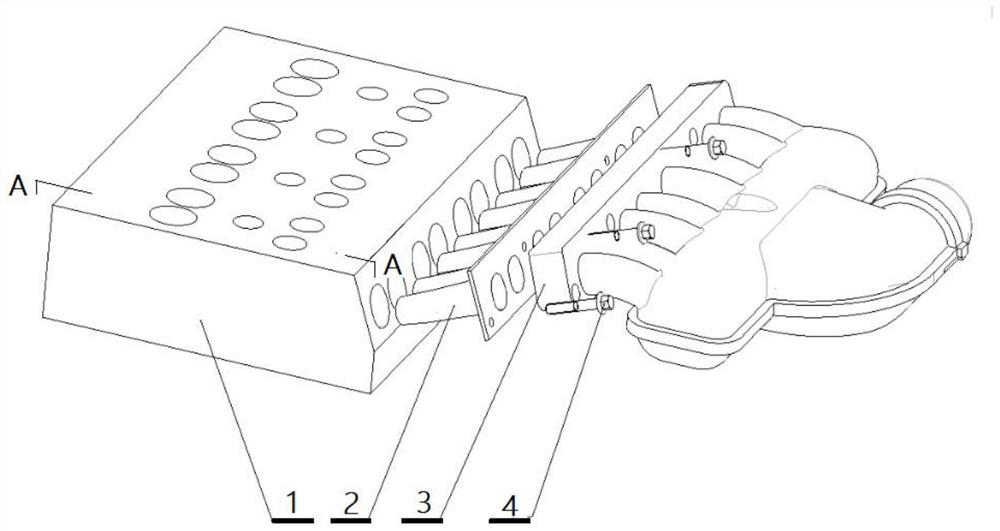

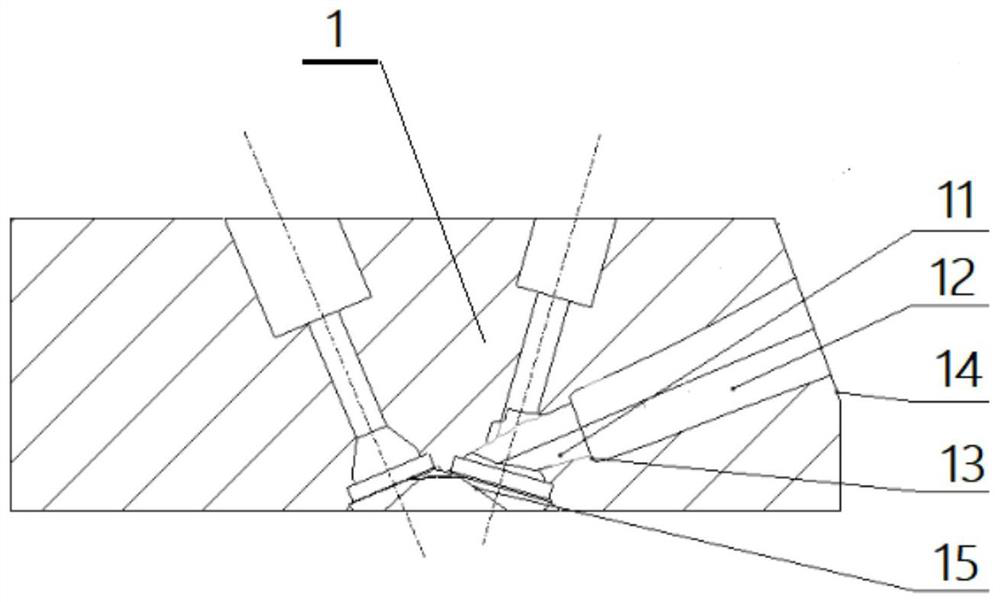

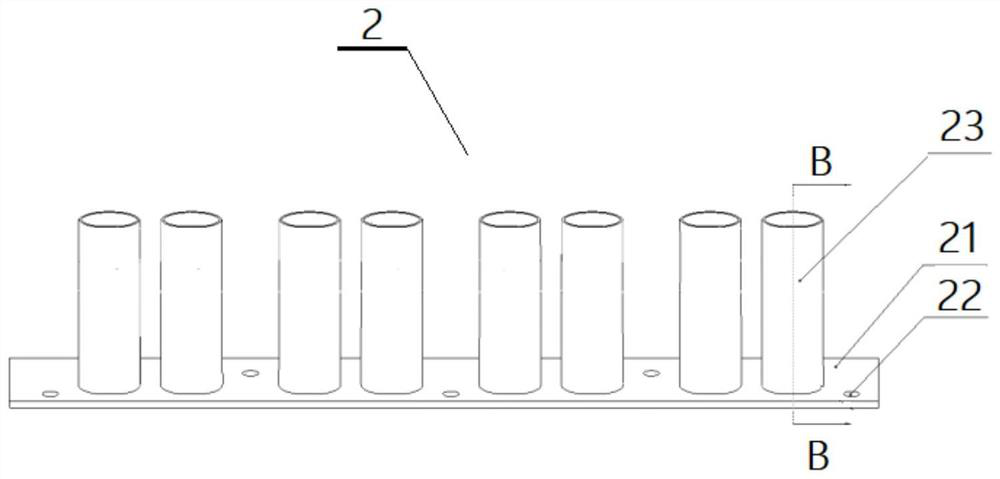

[0027] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] see Figure 1 to Figure 6 The heat insulation structure of the inlet passage on the cylinder head shown includes a cylinder head 1 and an intake manifold 3, and is characterized in that: a heat insulating member 2 is arranged between the intake manifold 3 and the cylinder head 1, and the insulation The thermal component 2 is connected and fixed to the cylinder head 1 and the intake manifold 3 through a plurality of mounting bolts 4; A plurality of bolt holes 22 are also provided; the cylinder head 1 is provided with a plurality of upper air intake passages 11, and the air intake end of each upper air intake passage 11 is provided with a heat-insulating component matching portion 12, where the heat-insulating member cooperates A step 13 is provided at the part where one end of the part 12 is connected with the upper air intake passage 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com