Probe for phase change detection

A technology for detecting containers and media, which is applied in the field of probes for detecting phase changes in containers, and can solve problems such as sensor intrusion, complicated cost, and sensor failure to piggage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

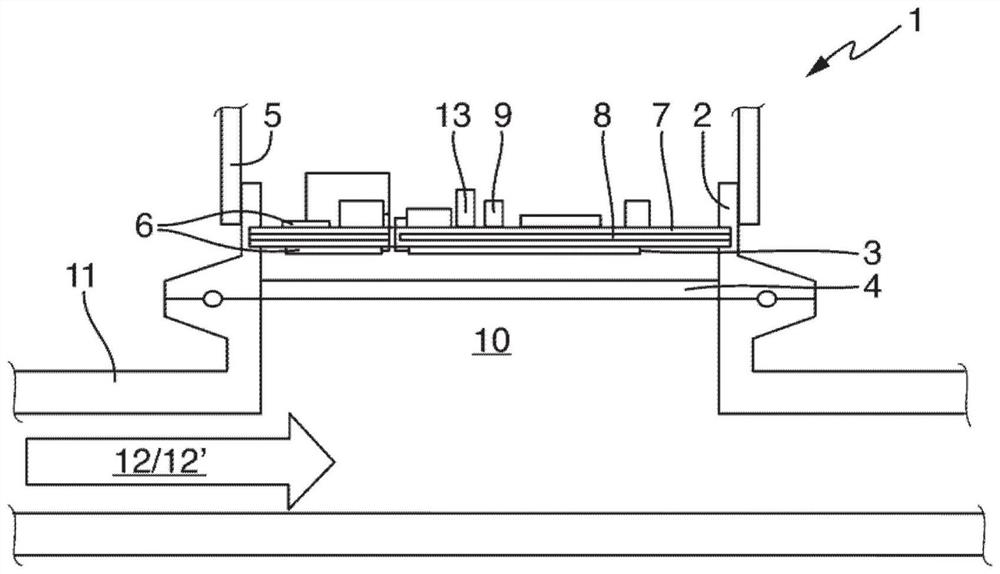

[0027] The claimed probe is denoted in its entirety by reference number 1, and in figure 1 shown in .

[0028] A hermetically sealed probe 1 of hygienic design is presented which detects phase boundaries of different liquid media in industrial processes by means of microwave technology. “Gas-tight” is understood in this context to mean that fluids such as the medium to be measured, air or dust cannot penetrate from the outside. Also does not include any electrical feedthroughs.

[0029] The probe 1 operates in the frequency range of 100 to 10000 MHz, but preferably in the range of 500 to 3000 MHz. The probe operates at at least one frequency.

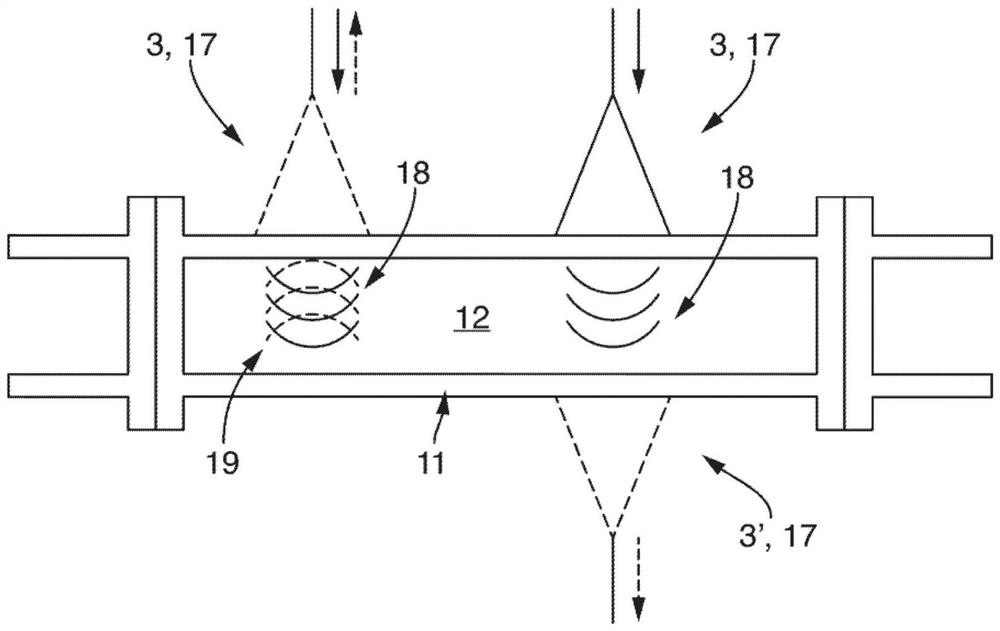

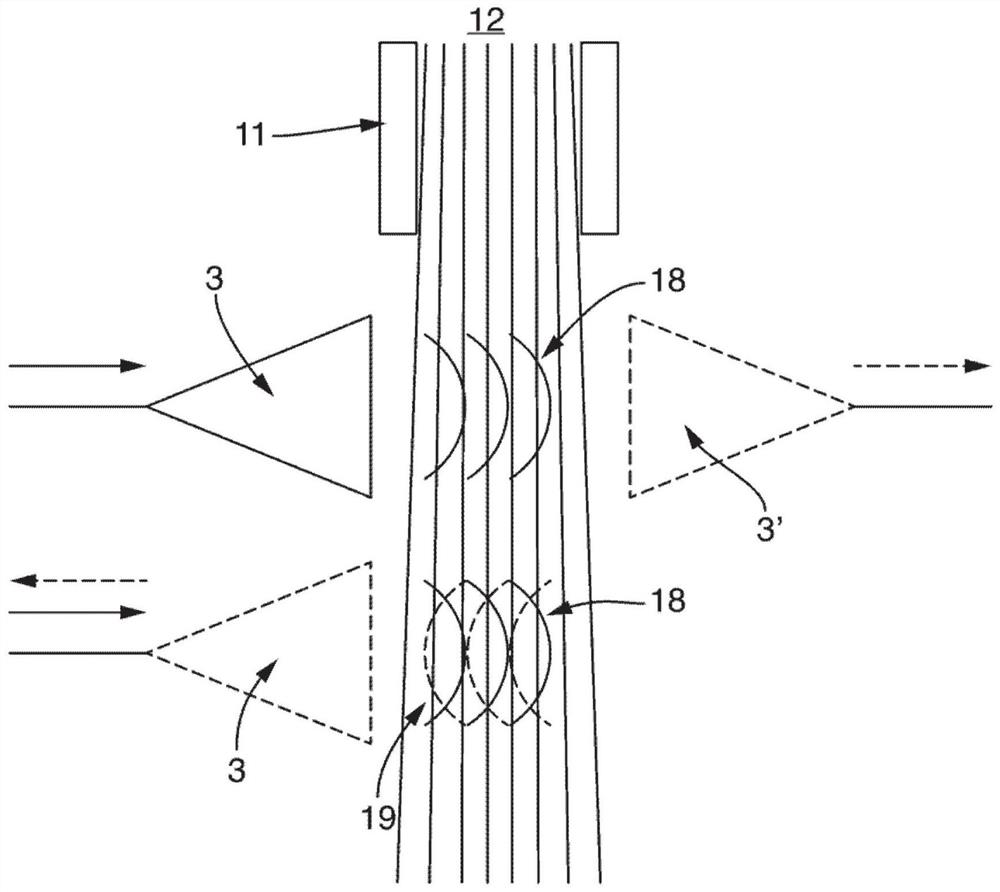

[0030] In one embodiment, instead of using only one measurement frequency, switching between several fixed frequencies occurs, or the measurement frequency is continuously changed within a defined range. Due to the different penetration depths or the available analyzable volume ranges, then, in addition to detecting the phase bounda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com