A method of running a multi-robot flexible production line for integral additive manufacturing

A flexible production line, multi-robot technology, applied in the field of mechanical processing, to achieve the effects of high processing accuracy, saving printing time, and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

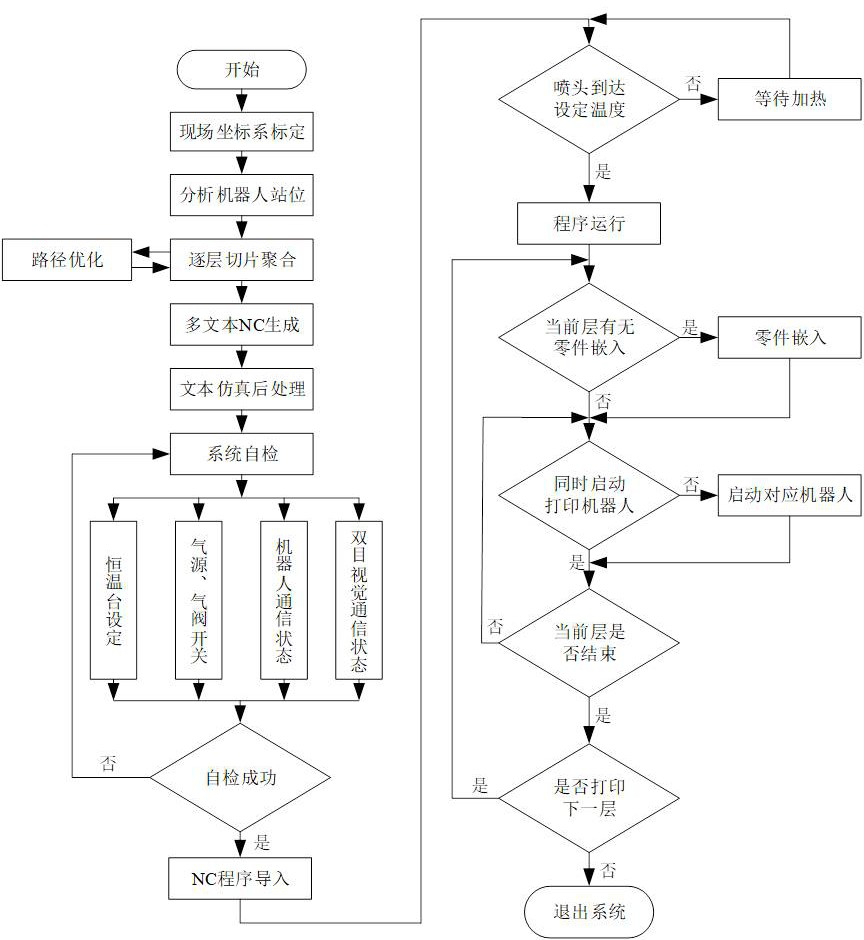

[0024] In order to clarify the technical solution and technical purpose of the present invention, the present invention will be further introduced below with reference to the accompanying drawings and specific embodiments.

[0025] The multi-robot flexible production line used in the operation method of the multi-robot flexible production line for integral additive manufacturing of the present invention includes: a matrix printing robot and a wire printing robot that are hung upside down on a two-degree-of-freedom gantry column, and an embedded robot arranged on the embedded column And a stage for placing printed products, wherein the specific structural connection relationship refers to the invention application with the publication number: CN112936230A. The operation method of the multi-robot flexible production line oriented to the overall additive manufacturing of the present invention can realize the substrate printing of the to-be-printed product, the wire printing and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com