Efficient design optimization method and system for super-large variable turbomachinery and application

A turbomachinery and optimization method technology, applied in design optimization/simulation, computer-aided design, special data processing applications, etc., can solve problems such as failure of Euler distance, inability to guide point addition, increase in time complexity, etc., to achieve dimensionality reduction , Maintain effective utilization and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

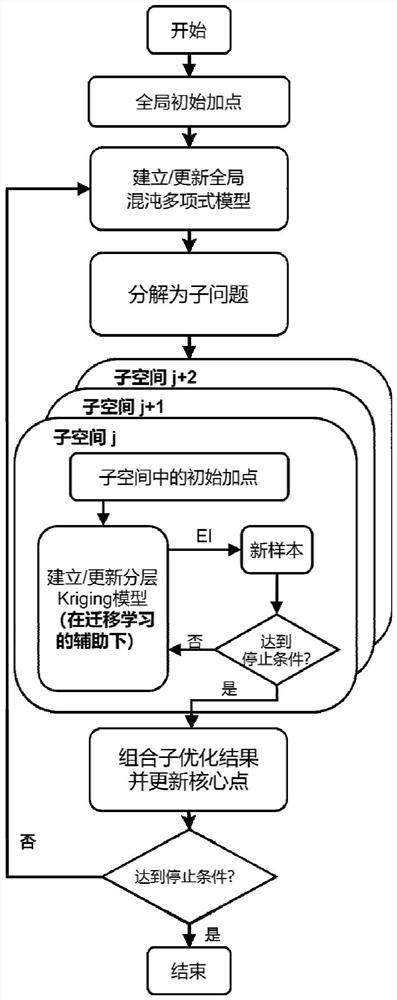

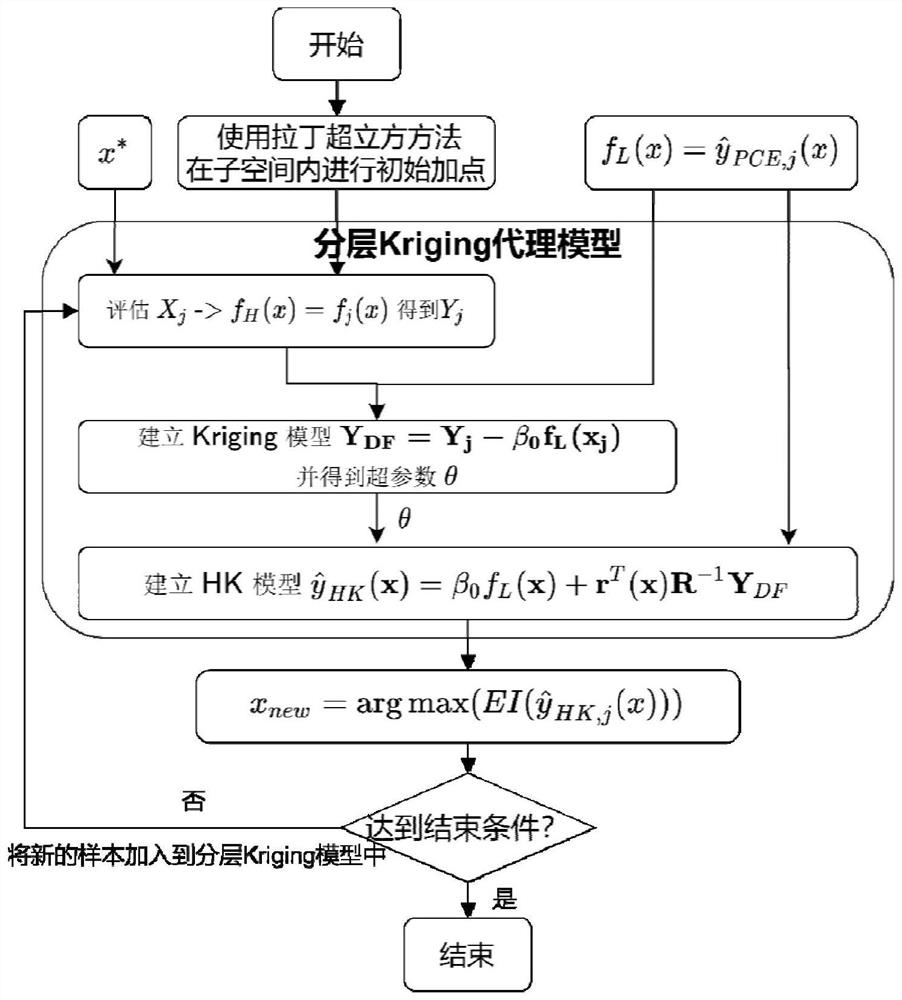

[0050] Such as figure 1 As shown, this embodiment provides a method for optimizing the efficient design of a super large variable turbomachinery and applies it to the optimization design of the compressor blade shape, specifically including the following steps:

[0051] 1. Establishment of design space

[0052] In this embodiment, the most widely used NASA ROTOR37 compressor blade model is selected as the design object. The blade is designed and tested by Reid and Moore of NASA Glenn Center. Five sections are cut from the three-dimensional blade object as the characteristic section of the shape, and five control points are selected on the suction surface of each section to adjust the shape of the suction surface curve. At the same time, three design parameters are selected to adjust the bending, twisting and sweeping state of the three-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com