Array substrate, manufacturing method of array substrate and display panel

A technology of an array substrate and a manufacturing method, which is applied in the field of display, can solve the problems of affecting the display quality of AMOLED display panels, unstable luminance of light-emitting devices, and poor stability, so as to increase the holding time of gate potential, improve display quality, The effect of drive current stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

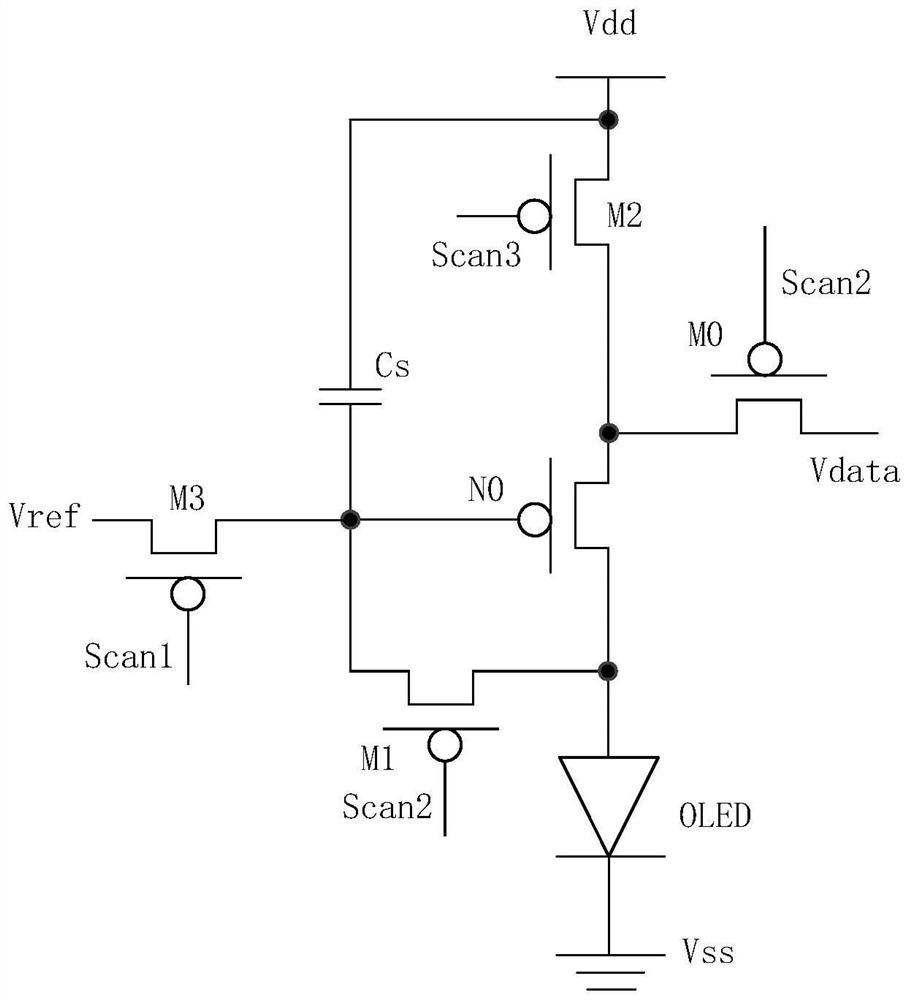

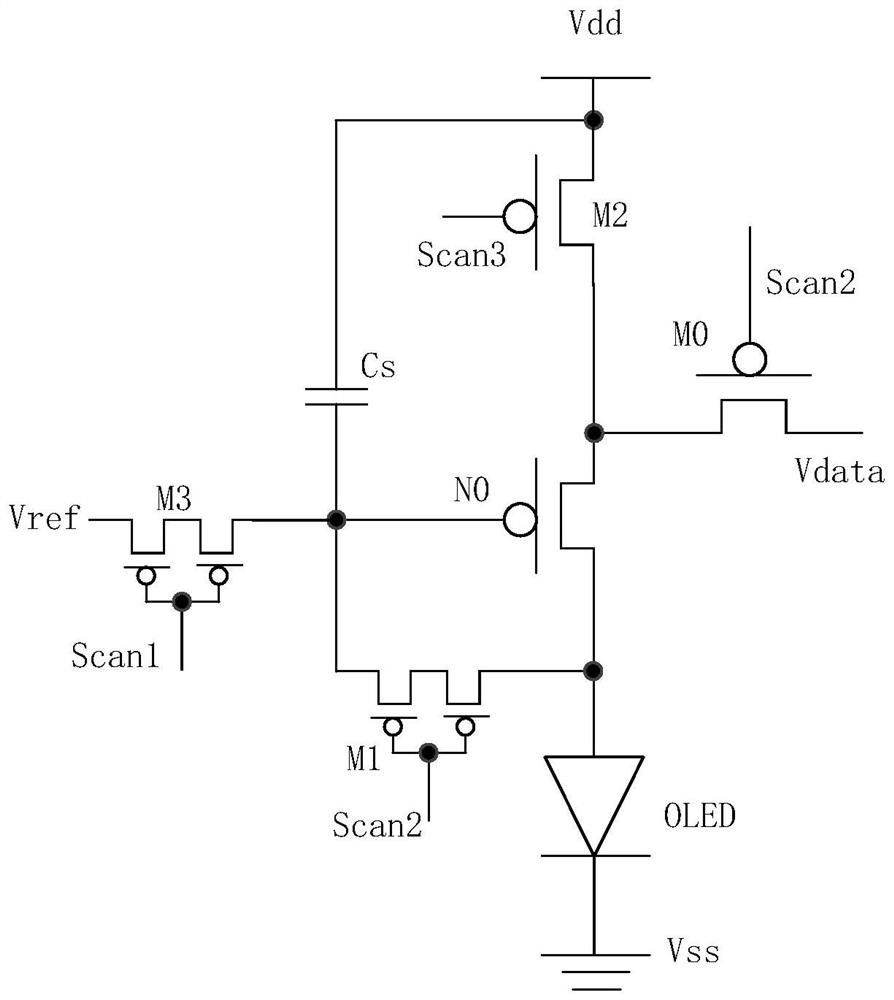

[0047] figure 1 A schematic structural diagram of a pixel driving circuit provided in the prior art. Such as figure 1As shown, the pixel driving circuit includes a switching transistor M0, a compensation transistor M1, a light emission control transistor M2, an initialization transistor M3, a driving transistor N0 and a storage capacitor Cs. The gate of the initialization transistor M3 is connected to the first scan line Scan1 to receive the first scan signal, the source is connected to the initialization signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com