Lamination material pressing method for solid electrolyte aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and solid electrolytes, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of foil prying, defective products, air bubbles, etc., and achieve the effect of great promotion value, practicability, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

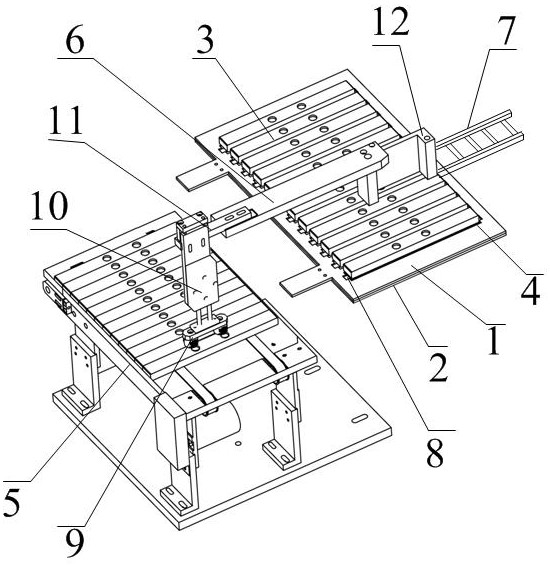

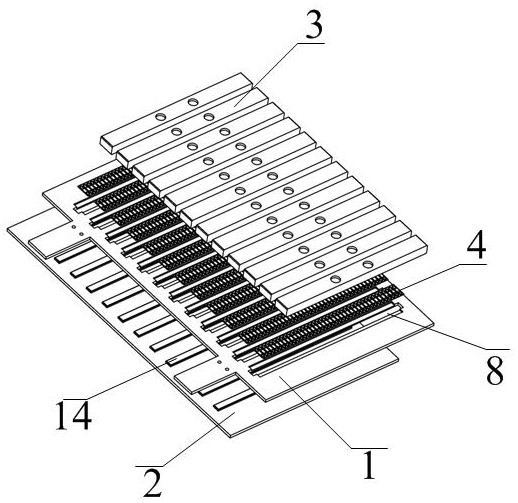

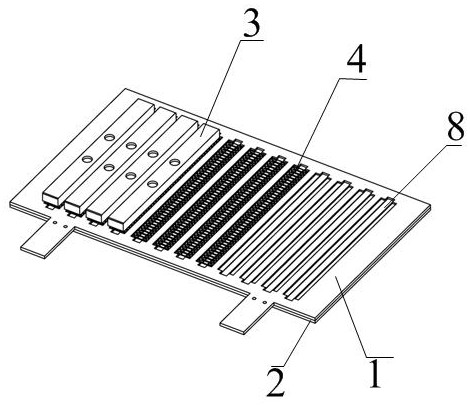

[0025] Embodiments of the present invention are described in further detail in conjunction with the accompanying drawings:

[0026] as attached Figure 1-Figure 9 As shown, a method for lamination and pressing of solid electrolyte aluminum electrolytic capacitors according to the present invention is characterized in that it includes a first tray 1, a second tray 2, a pressure block 3, a wire frame sheet 4, a conveyor table 5, Manipulator 6, sliding track 7; Hollow strip groove 8 is set in the middle of the first tray 1; The first tray 1 is tightly stacked on the top of the second tray 2; The wire frame sheet 4 is arranged on the second tray In a strip groove 8 in a tray 1; the manipulator 6 is composed of a clamp foot 9, a mechanical transmission 10, a bracket 11, and a sliding block 12; the wire frame sheet 4 is placed with a foil stack 13, and the foil One end of the sheet stack 13 is fixedly connected to the wire frame sheet 4 by cold welding, and the foil stacks 13 are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com