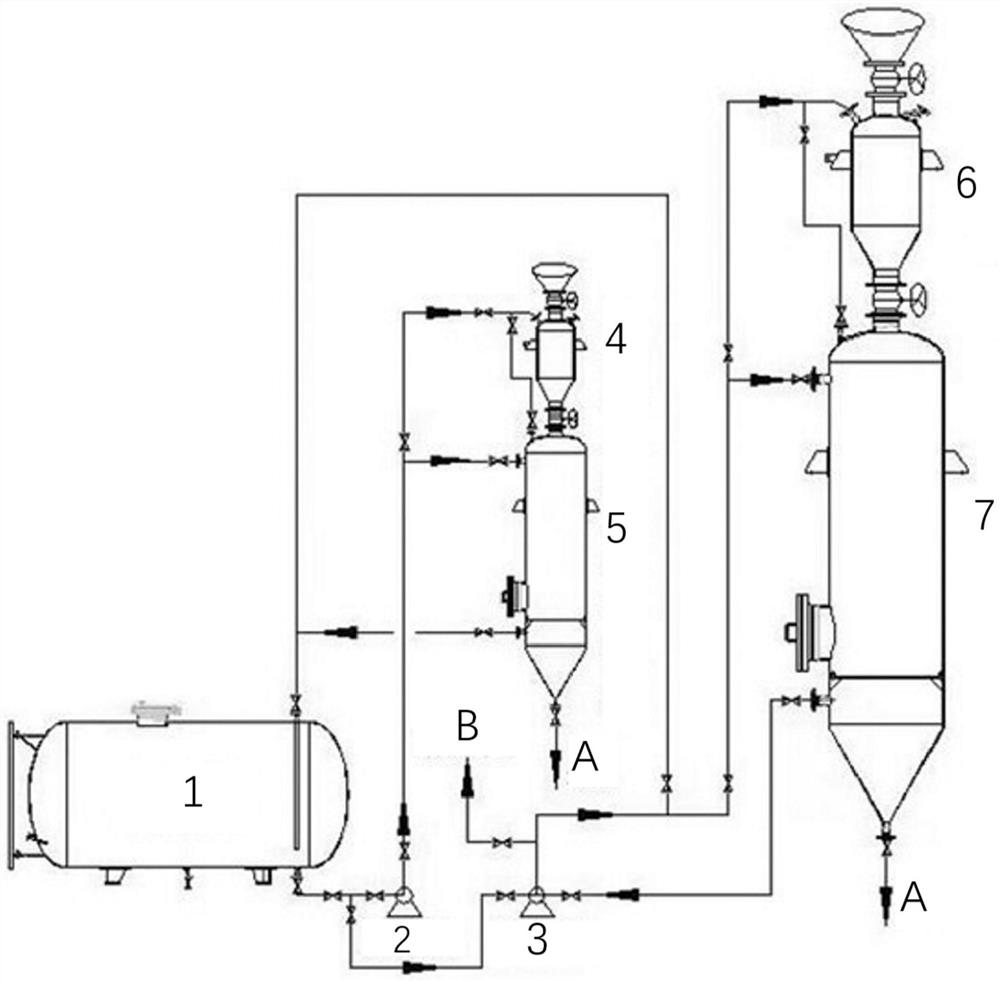

Device and method for removing moisture in liquid chloromethane through multi-stage drying

A technology for drying and drying of methyl chloride, which is applied in the field of devices for multi-stage drying to remove moisture in liquid methyl chloride, which can solve the problems of not giving the impurity removal method and achieve the effect of prolonging the replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) 18.0m of methyl chloride to be dried 3 (0.1% water content, 98.97% purity) into the methyl chloride storage tank;

[0045] (2) Turn on the 1# circulation pump subsequently, and the methyl chloride will be 3 The amount per hour is injected into the upper part of the first-stage circulating drying bed, and the temperature of the first-stage circulating drying bed is controlled at 32.5°C. The methyl chloride is dried by the anhydrous calcium chloride in the circulating drying bed and then returned to the methyl chloride storage tank. Circulate between the primary circulating drying bed and the methyl chloride storage tank, and return the methyl chloride to the methyl chloride tank after 80.0 minutes of circulating drying (water content is 0.07%, purity 99.45%);

[0046] (3) Turn on the 2# circulation pump, and use 25.0m of methyl chloride 3 The amount per hour is injected into the upper part of the secondary circulating drying bed, and the temperature of the secondar...

Embodiment 2

[0048] (1) 18m of methyl chloride to be dried 3 (0.12% water content, 98.95% purity) into the methyl chloride storage tank;

[0049] (2) Turn on the 1# circulation pump subsequently, and the methyl chloride is 3 The amount per hour is injected into the upper part of the first-stage circulating drying bed, and the temperature of the first-stage circulating drying bed is controlled at 33.2°C. The methyl chloride is dried by the anhydrous calcium chloride in the circulating drying bed and then returned to the methyl chloride storage tank. Circulate between the primary circulating drying bed and the methyl chloride storage tank, and return the methyl chloride to the methyl chloride tank after circulating and drying for 85 minutes (water content is 0.06%, purity 99.46%);

[0050] (3) Turn on the 2# circulating pump, and use 25m of methyl chloride 3 The amount per hour is injected into the upper part of the secondary circulating drying bed, and the temperature of the secondary cir...

Embodiment 3

[0052] (1) 18m of methyl chloride to be dried 3 (0.15% water content, 98.93% purity) into the methyl chloride storage tank;

[0053] (2) Turn on the 1# circulation pump subsequently, and the methyl chloride is 30m 3 The amount per hour is put into the upper part of the primary circulating drying bed, and the temperature of the primary circulating drying bed is controlled at 30°C. The methyl chloride is dried by the anhydrous calcium chloride in the circulating drying bed and then returned to the methyl chloride storage tank. Circulate between the primary circulating drying bed and the methyl chloride storage tank, and return the methyl chloride to the methyl chloride tank after circulating and drying for 60 minutes (the water content is 0.08%, the purity is 99.43%);

[0054] (3) Turn on the 2# circulating pump, and use 25m of methyl chloride 3 The amount per hour is injected into the upper part of the secondary circulating drying bed, and the temperature of the secondary cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com