Continuous kettle type 2, 6-methyl ethyl phenyl-methylenimine production device and method

A technology of methyl ethyl phenyl and methyl ethyl aniline, which is applied in the field of 2,6-methyl ethyl phenyl-methyl imine production equipment, can solve the problem of easy leakage of reaction waste gas and waste water, harm to the environment and staff, and unstable product quality and other problems, to achieve the effect of improving resource utilization, reducing material and energy loss, and improving absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

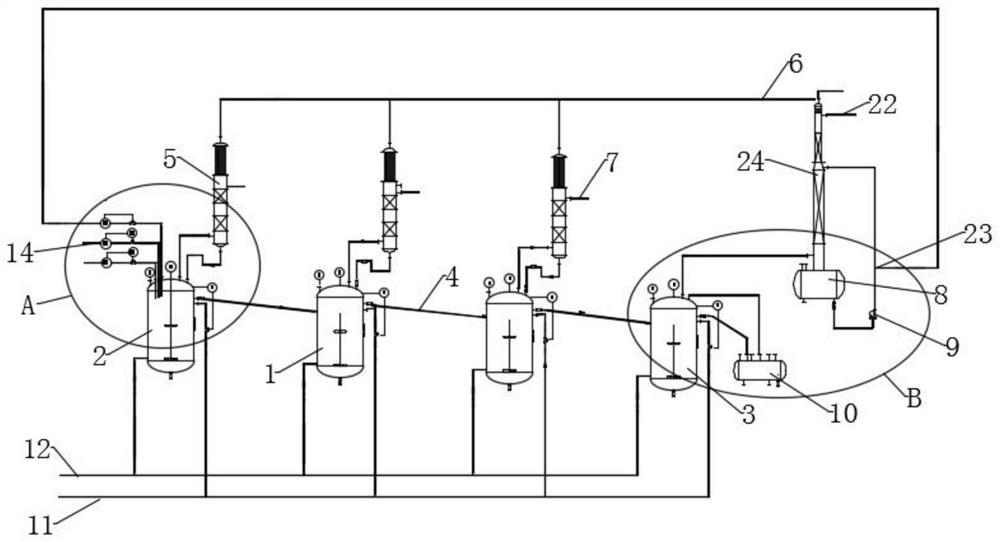

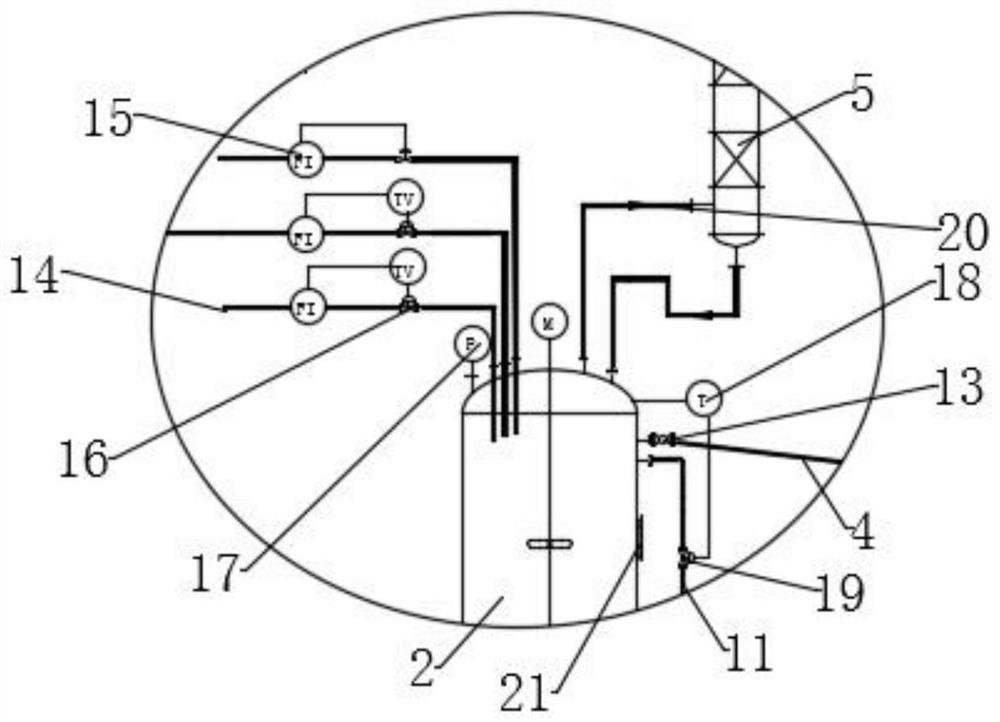

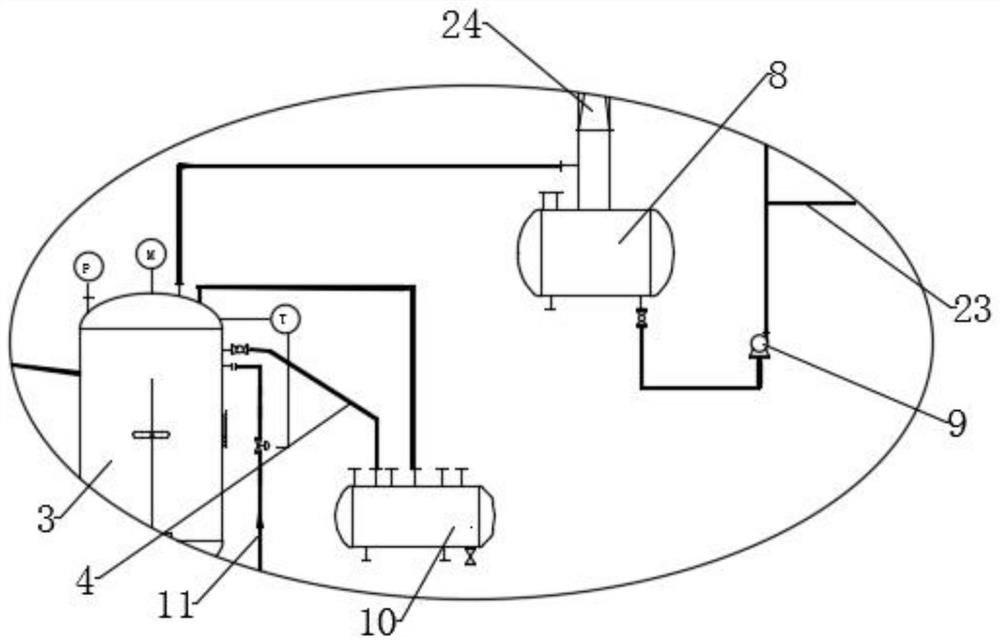

[0025] Example: such as Figure 1 to Figure 3 As shown, the present invention provides a continuous tank type 2,6-methylethylphenyl-methanimine production device, comprising a plurality of reactors 1, and the plurality of reactors 1 are connected in series through the overflow pipeline 4, and the first in series The reactor 1 at the end is set as the feed tank 2, the reactor 1 at the end of the series is set as the discharge tank 3, the feed tank 2 is fixedly connected with a plurality of feed pipes 14, and the discharge tank 3 is connected to the receiving tank through the overflow pipeline 4 10. The bottoms of multiple reaction kettles 1 are fixedly connected to the condensed water pipe 12, the inner cavity of the reaction kettle 1 is fixedly connected to the steam pipe 11, and the top gas phase area of the reaction kettle 1 at the front of the discharge kettle 3 is connected through a gas phase balance pipe 20 The bottom side of the purification tower 5 and the gas phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com