Electrolytic bacterial corrosion prevention system and method

A technology for bacterial corrosion and power generation devices, applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, mining wastewater treatment, etc., can solve problems such as increased use costs, reduce costs, avoid environmental pollution, reduce Effects of Bacterial Corrosion Risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

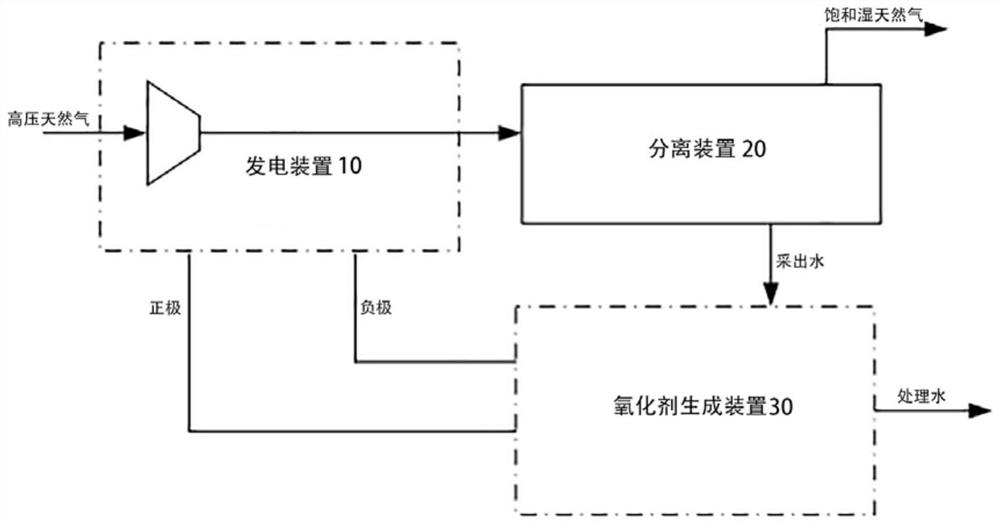

[0027] figure 1 It is a structural schematic diagram of the electrolytic anti-bacterial corrosion system of the embodiment of the present application. Combine below figure 1 The electrolytic anti-bacterial corrosion system of the present invention is described in detail.

[0028] Such as figure 1 As mentioned above, the electrolytic anti-bacterial corrosion system at least includes: a power generation device 10 , a separation device 20 and an oxidant generating device 30 . The power generation device 10 is used to access the natural gas produced from the underground reservoir, and use the output pressure energy of the natural gas to generate electricity. The separation device 20 is connected with the power generation device 10, and is used to obtain the natural gas passing through the power generation device 10, and separate it to obtain produced water. The oxidant generating device 30 is respectively connected with the power generating device 10 and the separating device ...

Embodiment 2

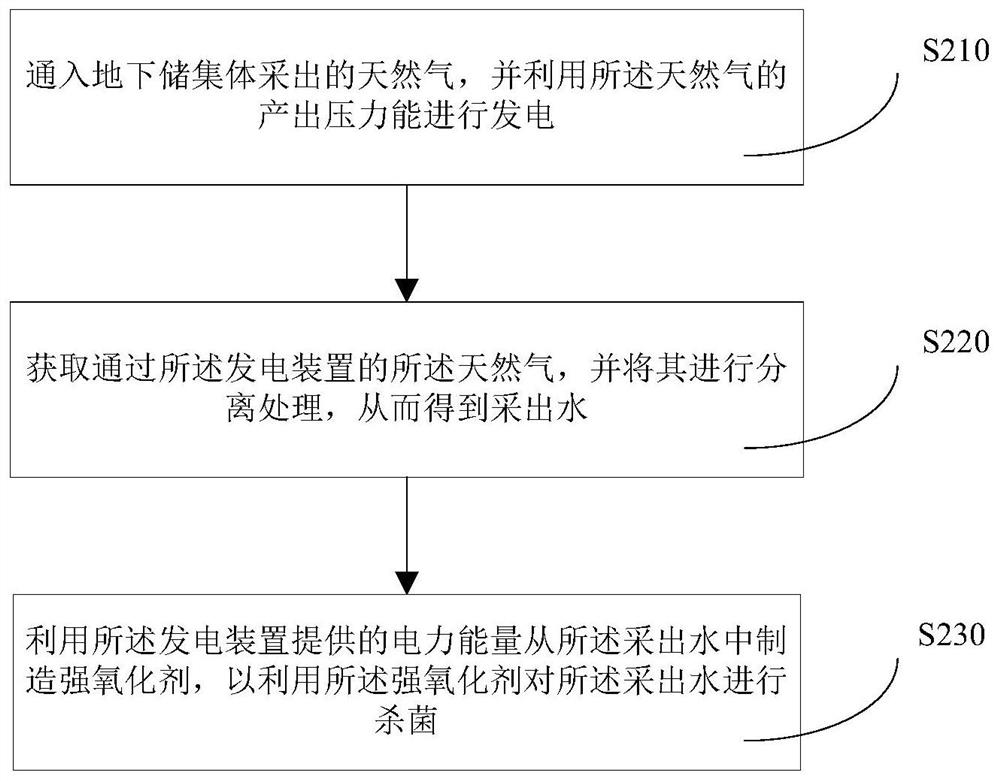

[0039] On the other hand, based on the above-mentioned electrolytic anti-bacterial corrosion system, the embodiment of the present invention also proposes an electrolytic anti-bacterial corrosion method, which utilizes the above-mentioned electrolytic anti-bacterial corrosion system to effectively realize the bacterial anti-corrosion function of the oil and gas field ground gathering and transportation system. figure 2 It is a method step diagram of the electrolytic anti-bacterial corrosion system of the embodiment of the present application. Such as figure 2 As shown, the electrolytic anti-bacterial corrosion system of the present invention includes the following steps: Step S210 feeds the natural gas extracted from the underground reservoir to the power generation device 10, and the power generation device 10 utilizes the output pressure energy of the extracted natural gas to generate electricity; Step S220 The separation device 20 obtains the natural gas passing through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com