Trunk whitewashing drip-proof device

A technique of white-painting the trunk and anti-drip technology, which is applied to the device for coating liquid on the surface, spraying device, coating, etc., which can solve the problems that crops cannot fully absorb, reduce effectiveness, and nutrient loss, and solve the problem of soil fertility decline Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

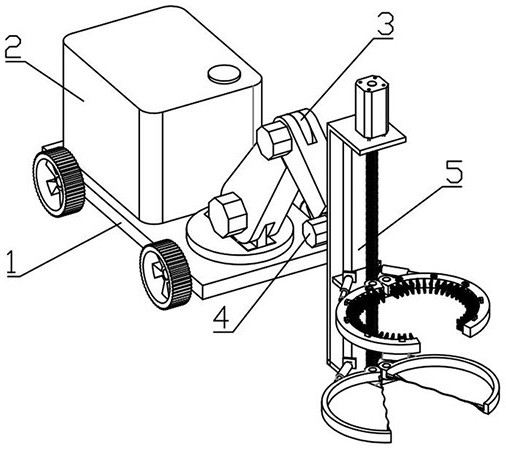

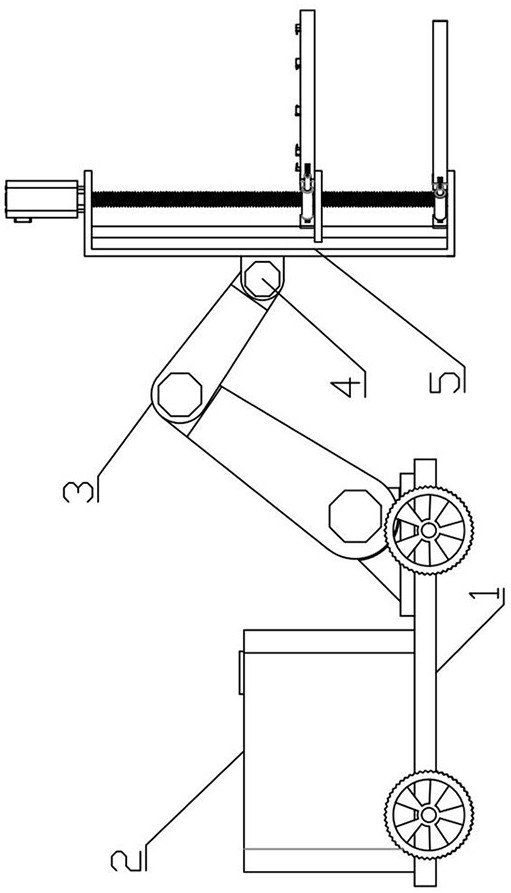

[0032] Such as figure 1 with 2 Shown is a schematic diagram of the overall structure of the present invention, the base of the trunk whitening anti-drip device is a car body 1, the left side of the car body 1 is fixed with a storage box 2 for storing whitening agent, and the right side is rotatably provided with a Mechanical arm 3, the end of mechanical arm 3 is connected with 5 shafts of anti-drip mechanism 5 by first electric shaft 4.

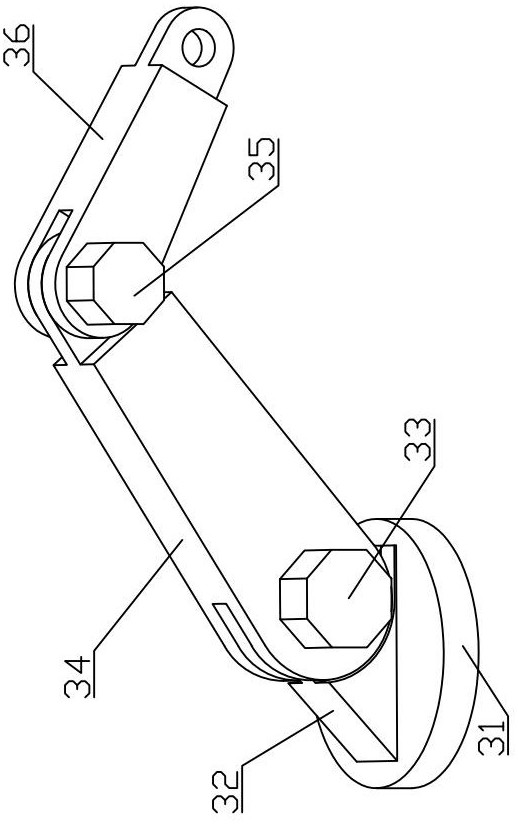

[0033] Such as image 3 Shown is a schematic diagram of the structure of the mechanical arm 3. The mechanical arm 3 is composed of a base 31, a large arm 34 and a small arm 36. The base 31 is rotatably connected to the vehicle body 1. A rib 32 is fixedly arranged on the base 31. One end of the large arm 34 is The second electric shaft 33 is axially connected to the rib 32, the other end is axially connected to one end of the small arm 36 through the third electric shaft 35, and the other end of the small arm 36 is axially connected to the a...

Embodiment 2

[0041] In this embodiment, other components except the anti-drip unit 542 are the same as those described in Embodiment 1. Anti-drip assembly 54 such as Figure 10 As shown, the anti-drip assembly 54 includes two semi-circular anti-drip units 542 arranged horizontally opposite each other. One end of the anti-drip unit 542 is connected to the frame bottom plate 541 through a second rotating shaft 543, and the outside of the anti-drip unit 542 is connected to The frame bottom plate 541 is fixedly connected, and the control of the second telescopic rod 544 can control the anti-drip unit 542 to open and merge. Such as Figure 11 Shown is a schematic structural diagram of the anti-drip unit 542. The anti-drip unit 542 includes a semi-circular second outer frame 5421, and a high-pressure air nozzle 5425 is evenly fixed inside the second outer frame 5421, and the high-pressure air nozzle 5425 faces the center of the circle.

[0042] In this embodiment, the working principle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com