Carbonitriding heat treatment equipment and method based on computer simulation

A heat treatment equipment, carbonitriding technology, applied in coatings, instruments, analytical materials, etc., can solve the problems of large sensor reading error, sensor erosion, easy damage to the sensor, etc., to protect the sensor, reduce erosion, and reduce leakage. the effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

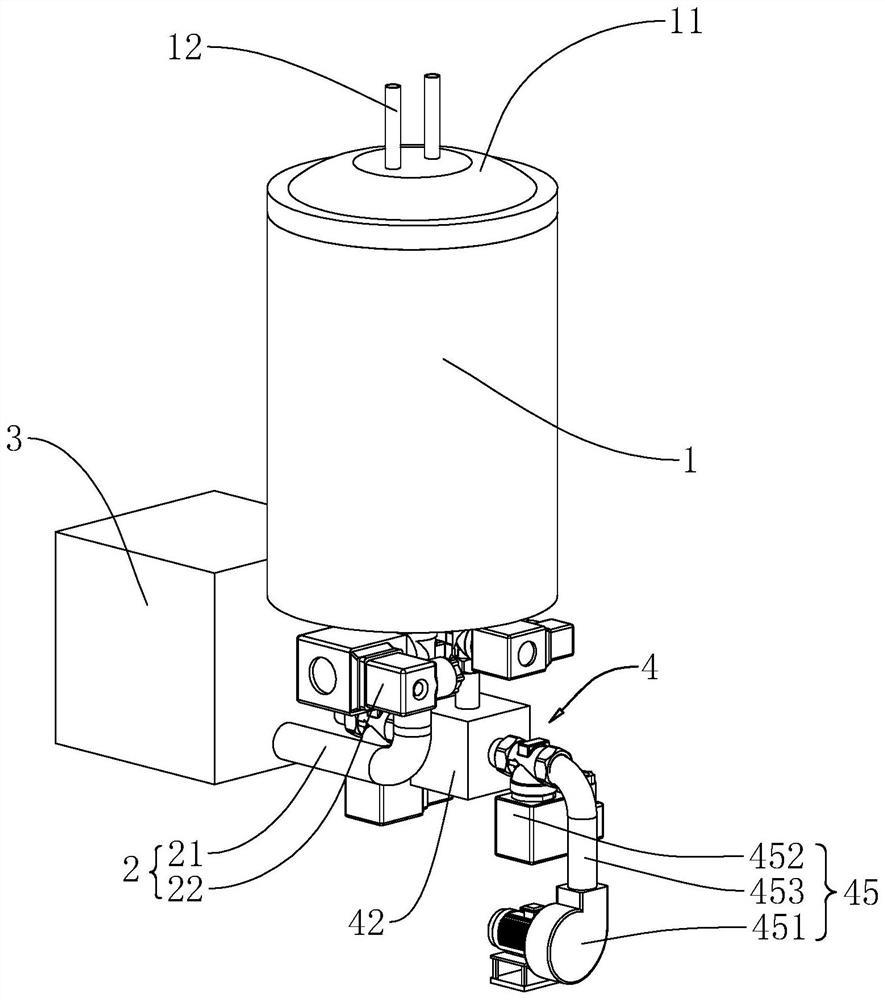

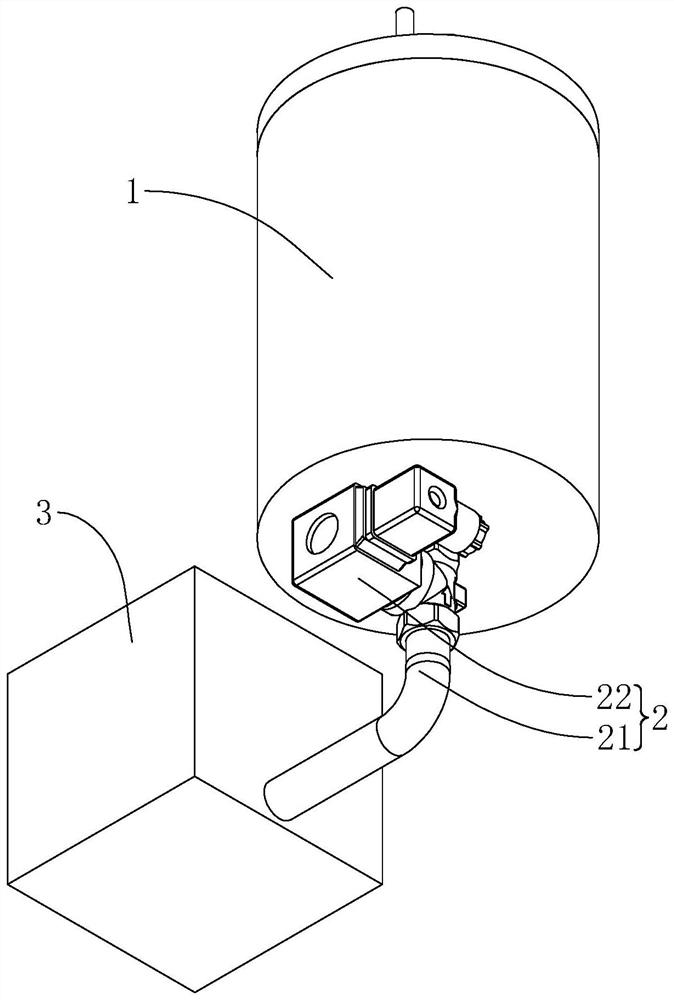

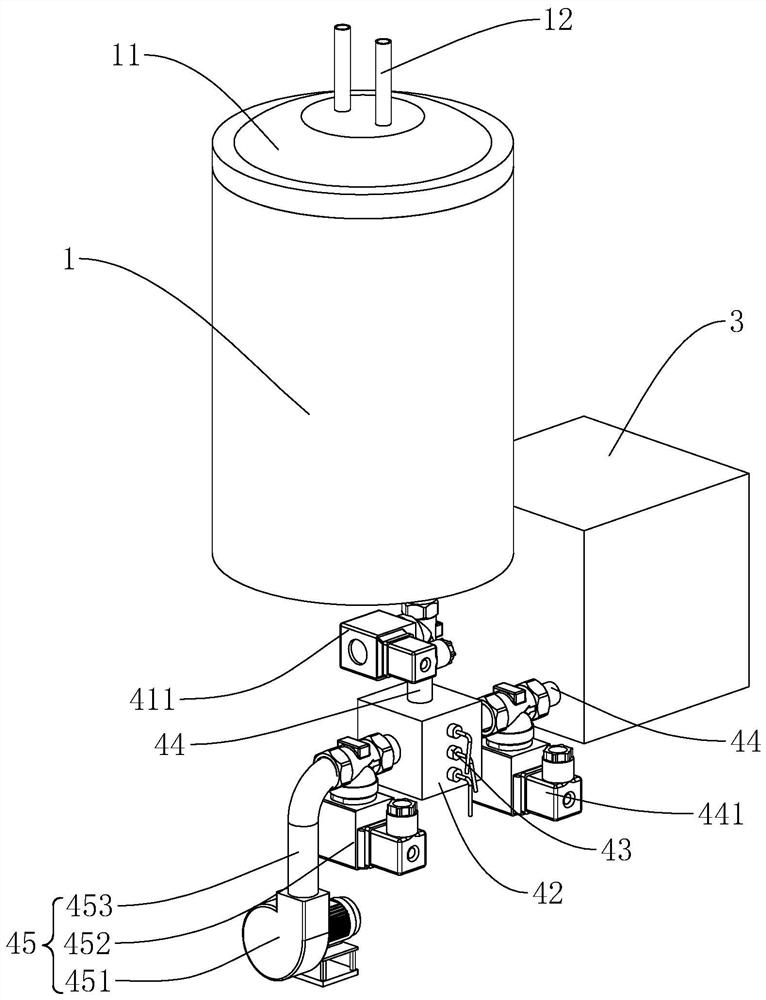

[0038] The following is attached Figure 1-3 The application is described in further detail.

[0039] The embodiment of the present application discloses a carbonitriding heat treatment equipment based on computer simulation. refer to figure 1 , comprising a furnace body 1, the furnace body 1 is used to hold workpieces, a cover body 11 is detachably connected to the furnace body 1, the cover body 11 is detachably connected to the furnace body 1, and the cover body 11 is set on the furnace body 1, thereby Make the inner cavity of the furnace body 1 form a sealed environment. The cover body 11 is provided with a plurality of feed pipes 12, the feed pipes 12 run through the cover body 11 and are fixedly connected to the cover body 11, the user can charge methanol, carbon monoxide, nitrogen or ammonia gas into the furnace through the feed pipes 12 In the body 1, the furnace body 1 can heat the workpiece and cause the carbonitriding reaction to occur on the surface of the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com