Intelligent roof snow removal system and method for pressure-bearing building

A technology for construction and snow melting, which is applied to buildings, building structures, roofs, etc., can solve the problems of easy occurrence of snow accumulation, icing, excessive energy consumption, and sealing failure of pressure-bearing houses, so as to improve the efficiency of snow melting and improve the overall structure. Streamlined, elevated temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

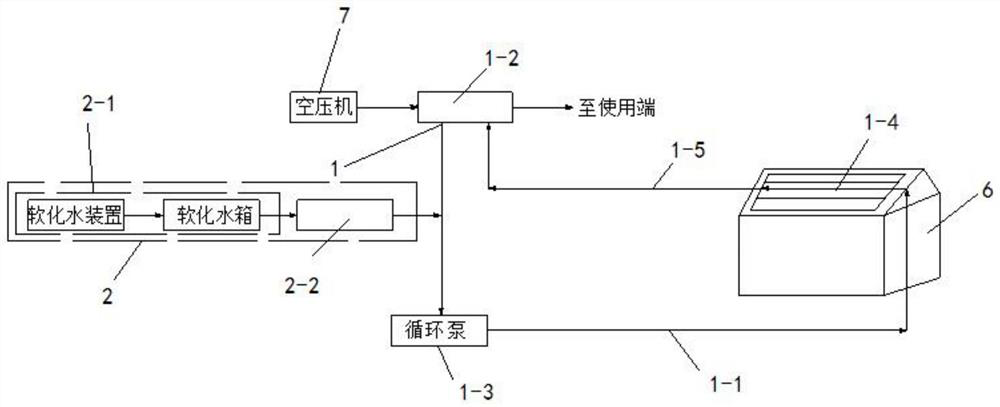

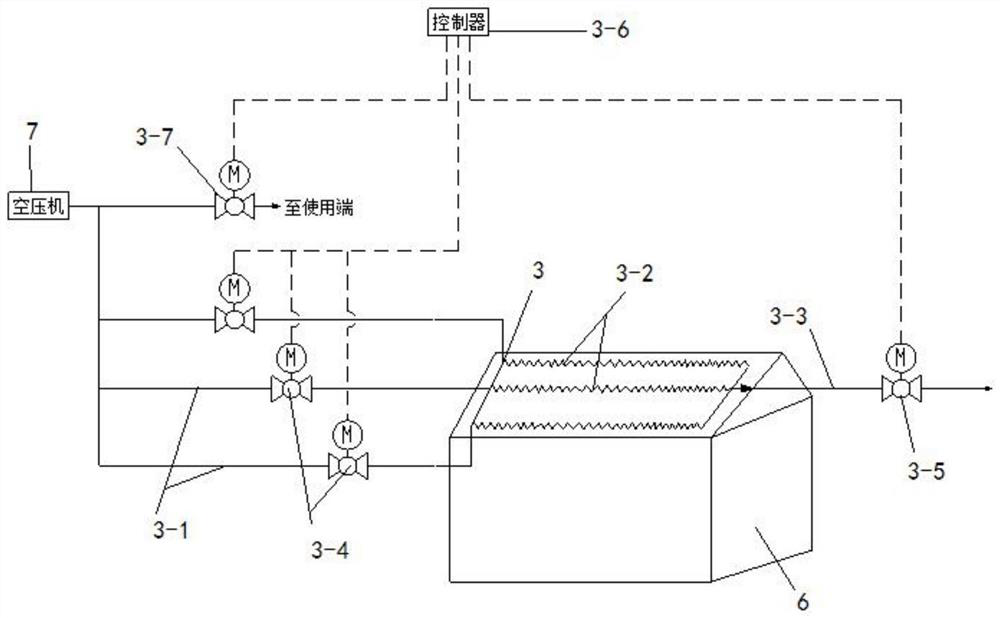

[0035] see figure 1 , an intelligent roof snow removal system for pressurized buildings, including a waste heat snow melting component 1 and a third high temperature medium supply device 2, specifically:

[0036] The waste heat snow melting assembly 1 includes pipeline A (labeled 1-1), heat exchanger 1-2, circulation pump 1-3, snow melting pipeline 1-4 and pipeline B (labeled 1-5); pressure-bearing building 6 The equipped air compressor 7 and heat exchanger 1-2 are arranged in sequence, and the heat exchanger 1-2 is used to cool the first high-temperature medium in the air compressor and transport it to the use end; the circulation pump 1-3, the pipeline B. The snowmelting pipeline 1-4 and the pipeline A form a medium circulation system in sequence, and the snowmelting pipeline 1-4 is arranged on the roof of the pressure-bearing building; the low-temperature medium in the pipeline A can be combined with the first high-temperature medium in the heat exchanger 1-2 Carry out hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com