Injection-production process for prolonging service life of coalbed methane production well group by injecting carbon dioxide

A technology of carbon dioxide and coalbed methane, which is applied in the field of injection and production technology, can solve the problems of gas production attenuation, short service life of coalbed methane production wells and production well groups, and short high production time, so as to achieve the extension of production increase, improve the long-term gas production effect, The effect of delaying the decay rate of gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

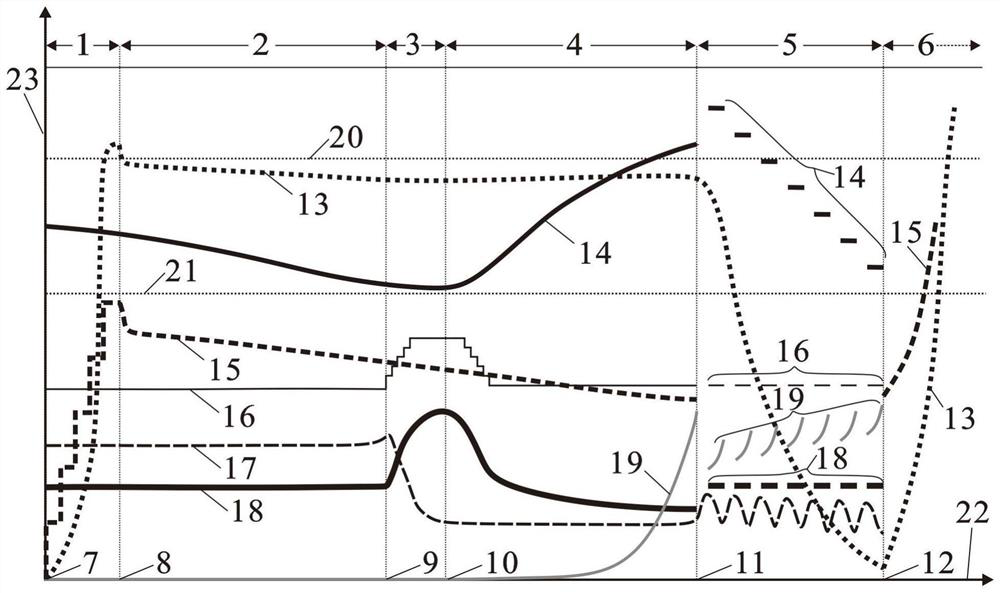

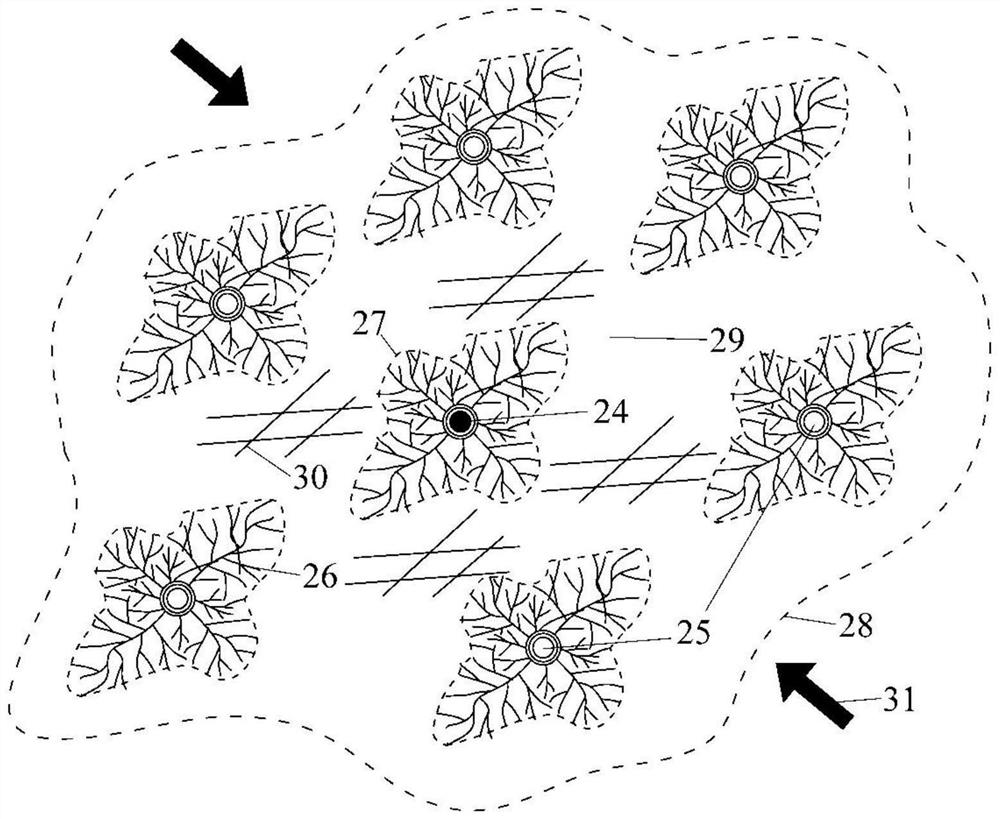

[0035] Embodiment 1: Injection-production process of the present invention: select the coalbed methane production well group that has been continuously produced for 4 to 6 years, and use the central well as CO 2 Injection wells, surrounding wells are gas production wells, using CO 2 to CH 4 The displacement and replacement effect of coalbed methane production wells can increase the daily gas production of gas production wells and prolong the service life of coalbed methane production well groups;

[0036] The injection-production process includes six stages: step-increased injection and pressure increase, pressure-limited injection displacement, gas drive water productivity suppression, gas production well stimulation, intermittent drainage, and gas production well site reclamation;

[0037] In the stage of stepped injection and pressure increase, the CO is rapidly increased by stepwise increasing the daily injection volume. 2 Injection well bottomhole pressure;

[0038] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com