Forced cooling room refrigerating unit and control method thereof

A control method and unit technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high compressor failure rate, poor unit stability, high energy consumption of refrigeration units, etc., to reduce the failure rate and reduce compression. The effect of reducing machine load and reducing overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

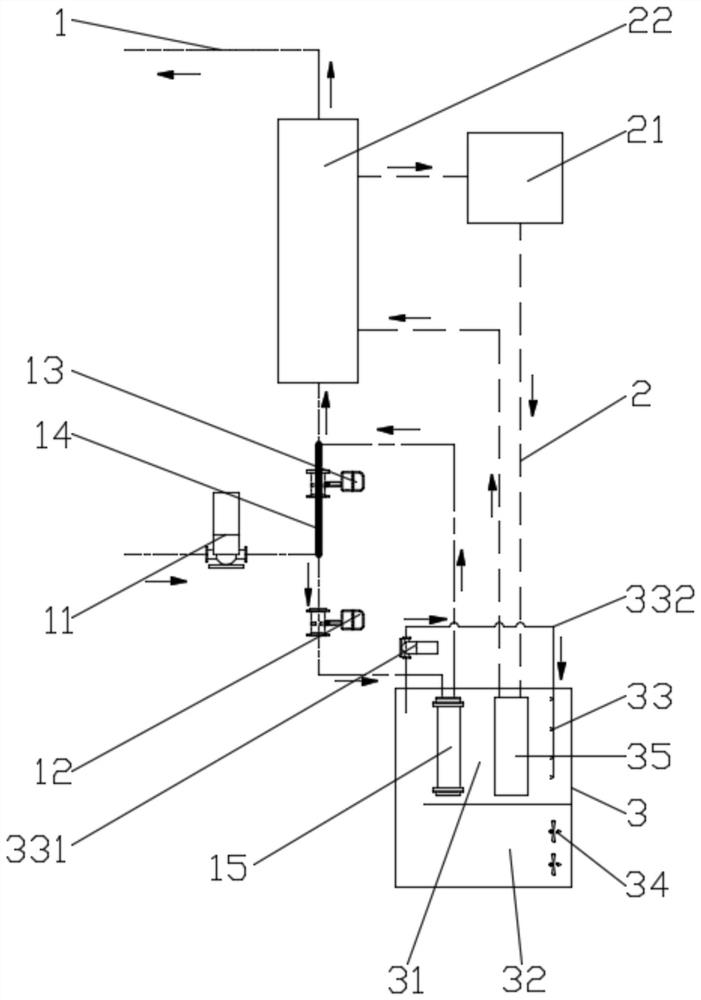

[0033] Such as figure 1A forced cooling evaporative refrigeration unit shown includes a compressor refrigeration device and a natural cooling device. The compressor refrigeration device includes a compressor 21, an evaporator 22, a refrigerant pipeline 2 and a water pipeline 1. The compressor 21 and evaporator 22 are set on the refrigerant pipeline 2, and the expansion valve, liquid storage tank, oil separator, etc. are also installed on the refrigerant pipeline 2; the water pipeline 1 includes a first water outlet and a first inlet The water outlet, the first water outlet is connected to the user end that needs to be cooled, the water pipeline 1 passes through the evaporator 22, and the water pipeline 1 is provided with a chilled water pump 11; chilled water flows in the water pipeline 1, Refrigerant flows in the refrigerant pipeline 2 . The process of evaporative cooling and cooling is as follows: the refrigerant is compressed by the compressor 21, from low-temperature and ...

Embodiment 2

[0043] An operation mode of a forced cooling evaporative cooling unit: including a manual mode and an automatic mode.

[0044] In this embodiment, the manual mode refers to manually selecting the refrigeration mode of the unit according to the needs of the user. In the shutdown state, the user can select compressor cooling or natural cooling cooling through the HMI human-machine interface. Compressor refrigeration then opens mechanical refrigeration valve 13, closes natural cooling valve 12, adopts natural cooling then opens natural cooling valve 12, closes mechanical refrigeration valve 13. Detect the position of the valve after waiting for 60 seconds for the valve to switch, and if it is abnormal, it will stop and send an alarm. With this manual switching function, customers can switch according to their needs. For example, the low temperature in winter is set to natural cooling mode, and the high temperature in summer is set to compressor cooling.

[0045] In this embodim...

Embodiment 3

[0050] In the method for controlling the unit in the forced cooling room, the unit also includes a control system for controlling the operation of the unit, and the steps are as follows:

[0051] In compressor refrigeration mode; the control method of the unit, the steps are as follows:

[0052] Step 1: The unit opens the mechanical refrigeration valve 13 and closes the natural cooling valve 12, so that the chilled water flows through the natural cooling pipe 15 first and then through the evaporator 22.

[0053] Step 2: Turn on the chilled water pump 11 to circulate the chilled water in the water pipeline 1 through the set pump cycle time, and the water flow switch on the chilled side detects the water flow signal and feeds it back to the control system.

[0054] Step 3: Determine whether to turn on the cooling water pump 331 according to the return temperature of the chilled water.

[0055] Step 4: According to the temperature of the cooling water in the water tower 3, deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com