Annular ultrasonic phased array detection device for PE pipeline welding seam detection

An ultrasonic phased array, weld inspection technology, applied in measuring devices, solids analysis using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, etc. Visually observe whether there are defects in the welded joints of the pipeline, so as to avoid overheating and water waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

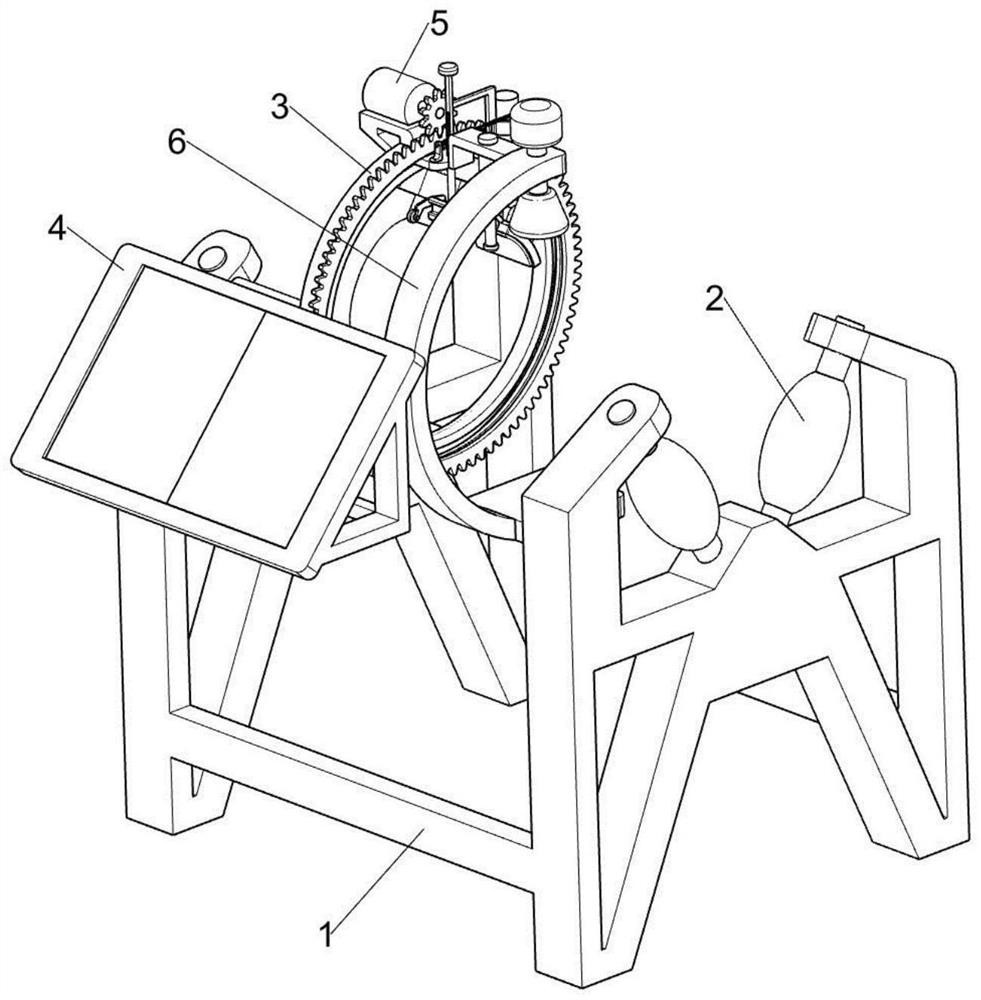

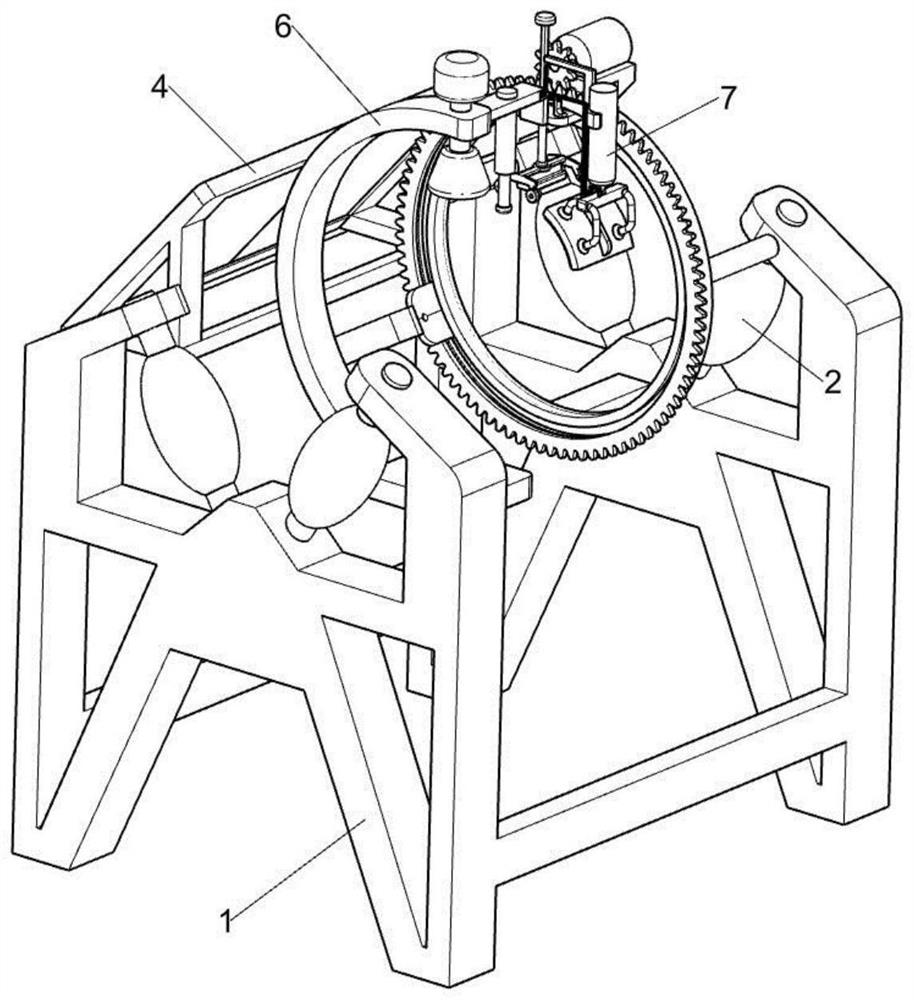

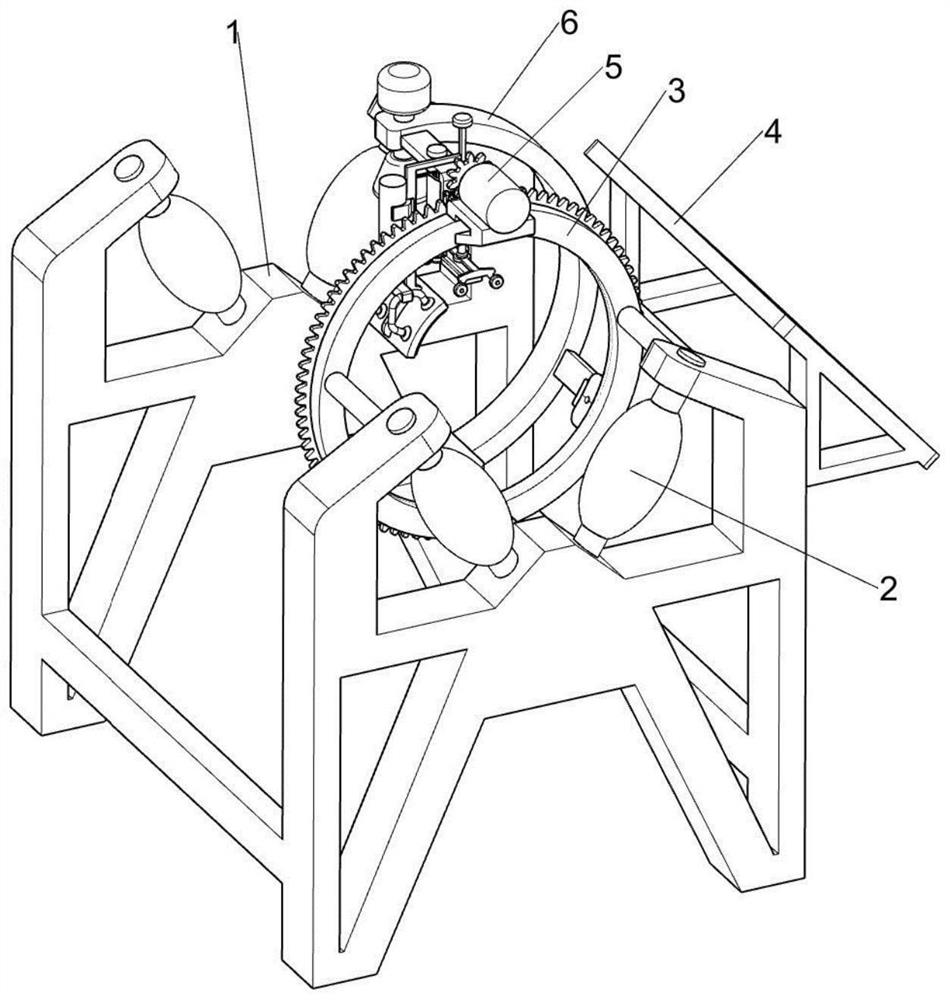

[0041] A circular ultrasonic phased array detection device for PE pipe weld detection, such as Figure 1-9As shown, it includes a base 1, a movable wheel 2, a fixed groove ring frame 3, a display 4, an annular ultrasonic phased array detection component 5 and an X-ray digital imaging detection component 6, and a pair of movable wheels 2 are symmetrically rotated on the base 1. , the rear of the base 1 is fixedly installed with a fixed groove ring frame 3, the display 4 is fixedly installed on the left side of the base 1, the display 4 is used to display real-time detection two-dimensional images, and the annular ultrasonic phased array detection component 5 is arranged on the fixed groove ring frame 3, the annular ultrasonic phased array detection component 5 is provided with an X-ray digital imaging detection component 6, and the X-ray digital imaging detection component 6 is used to perform digital imaging detection on the hot-melt joint by using X-ray rays.

[0042] The ann...

Embodiment 2

[0047] On the basis of Example 1, such as Figure 9-11 As shown, it also includes a weld humidification assembly 7, the weld humidification assembly 7 is arranged on the lifting groove rod 56, the weld seam humidification assembly 7 is used to cool down the welded joint of the pipeline, and the weld seam humidification assembly 7 includes a fixed L-shaped rod 71. Fixed arc plate 72, fixed card slot 74, fixed water storage tank 75, water distribution tank 76, first water distribution pipe 77 and second water distribution pipe 78, and a fixed L-shaped rod 71 is fixedly connected to the top of the lifting groove rod 56, and the fixed L-shaped rod 71 is fixed. The bottom of the shaped bar 71 is welded with a fixed arc plate 72, and the top of both sides of the fixed L-shaped bar 71 is fixedly connected with a fixed card slot 74, and the two fixed card slots 74 are connected with a fixed water storage cylinder 75 for water storage in a common ferrule type. The lower side of the fix...

Embodiment 3

[0050] On the basis of Example 2, such as Figure 10-12 As shown, it also includes a humidification restriction assembly 8, which is arranged on the top surface of the water distribution tank 76, and the humidification restriction assembly 8 is used to control the outflow of water in the fixed water storage cylinder 75, and the humidification restriction assembly 8 includes a fixed rack 81, curved rod 82, rotating shaft 83, rotating gear 84, fixed groove block 85, driving lever 86, tension spring 87 and disc valve 88, fixed tooth bar 81 is fixedly connected on the fixed semi-arc frame 61, and water distribution tank 76 top The surface is fixedly connected with a curved rod 82 for support, and the bottom of the fixed water storage cylinder 75 is connected with a rotating shaft 83 in a rotational manner. The rotating shaft 83 is fixedly connected with a rotating gear 84. 83 is fixedly connected with a fixed groove block 85, and the fixed groove block 85 is provided with slots in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com