Design method and device for medium-deep layer buried pipe heat pump heating system

A technology of heating system and design method, applied in hot water central heating system, heating system, geothermal energy and other directions, can solve the problems of difficult system design, low system efficiency, large floor space, etc., and achieve the effect of breaking through technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

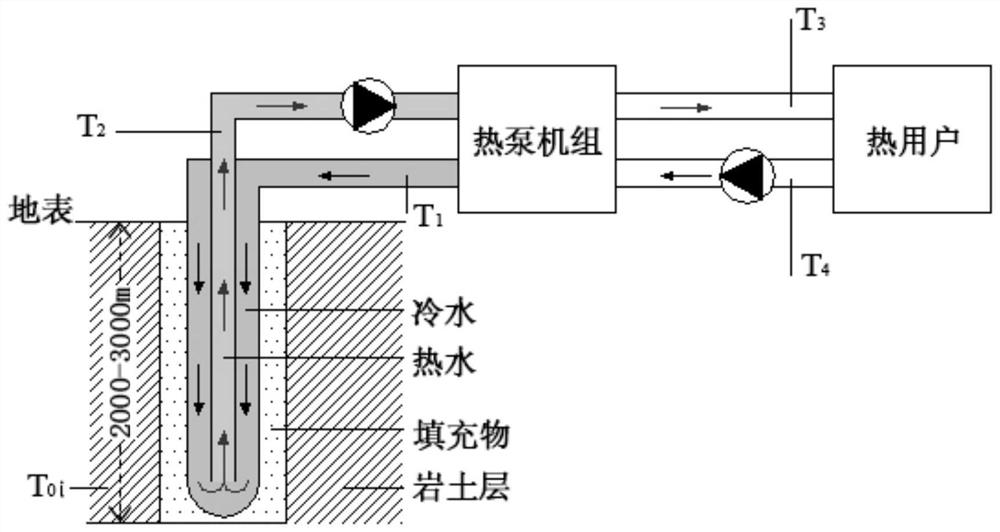

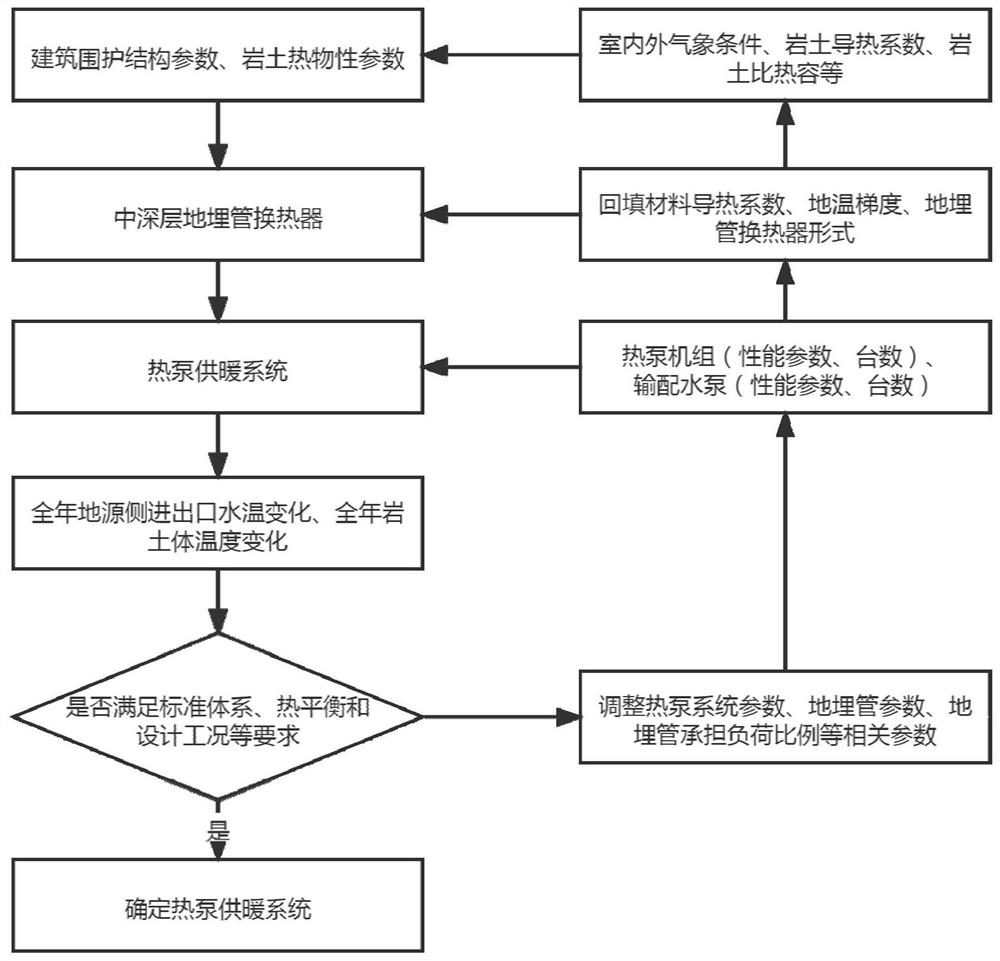

[0065] Implementation Mode 1. Refer to image 3 To illustrate this embodiment, this embodiment provides a design method for a mid-to-deep buried pipe heat pump heating system, and the method includes:

[0066] Building heating load steps for collecting building envelope parameters;

[0067] The geotechnical thermophysical property parameter step of collecting geotechnical thermophysical property parameter;

[0068] According to the collected building envelope parameters and geotechnical thermophysical parameters, the heat exchange steps of medium and deep buried pipes are output to the heat exchange results;

[0069] A step for determining a heat pump heating system based on an output result of the heat exchange step of the medium-deep buried pipe;

[0070] The heat exchange steps of the medium-deep buried pipe are specifically:

[0071] Processing the building envelope parameters and the geotechnical thermophysical property parameters through a heat transfer model;

[007...

Embodiment approach 2

[0083] Implementation mode two, refer to image 3 This embodiment is described. This embodiment is a further limitation of the design method for the mid-deep buried tube heat pump heating system provided in Embodiment 1. The method also includes:

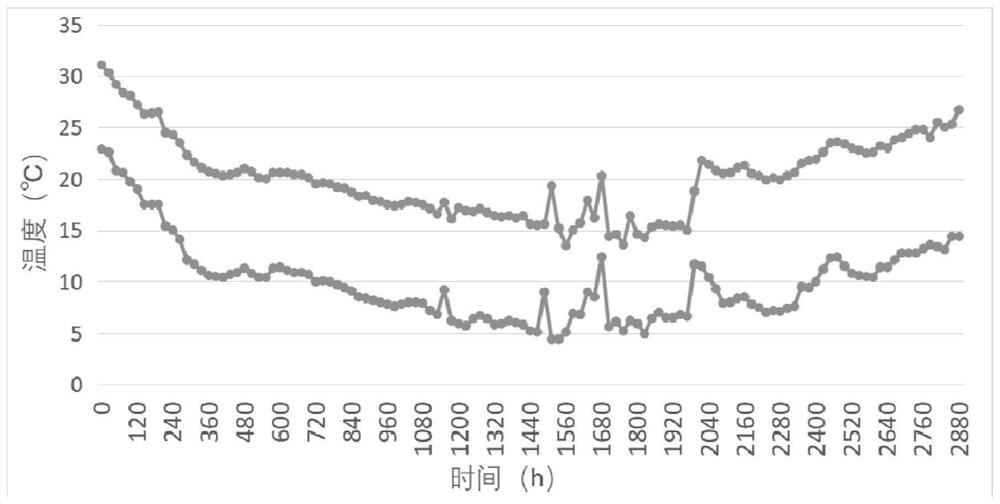

[0084] The water temperature collection step of collecting the water temperature change at the inlet and outlet of the ground source side;

[0085] A temperature collection step for collecting temperature changes of rock and soil mass;

[0086] According to the collected water temperature changes at the inlet and outlet of the ground source side and the temperature changes of the rock and soil mass, the judgment steps of judging whether the requirements of the standard system, heat balance and design conditions are met;

[0087] When the judging result output by the judging module is unsatisfactory, the step of adjusting the parameters in the system is adjusted.

[0088] The benefit of this embodiment is that: the steps of judgmen...

Embodiment approach 3

[0089] Embodiment 3. This embodiment is a further limitation of the design method for the mid-deep buried pipe heat pump heating system provided in Embodiment 1. The initial temperature expression equation of the initial ground temperature in the formation at any depth is:

[0090]

[0091] Among them, t (z) represents the initial temperature of formation at any depth, t a Indicates the surface temperature in °C, q g Indicates the heat flow of the earth, the unit is W / m 2 , h a Indicates the convective heat transfer coefficient between the air and the surface, in W / (m 2 K), k j Indicates the heat transfer coefficient of rock and soil, H j Indicates the coordinates of the bottom of layer j, k m Indicates the heat transfer coefficient of rock and soil, in W / (m 2 K), z represents any depth of rock and soil mass;

[0092] According to the assumption of the heat transfer model, it is considered that the initial temperature distribution is uniform in the radial direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com