Method for detecting printing carbon line defects of humidity sensor

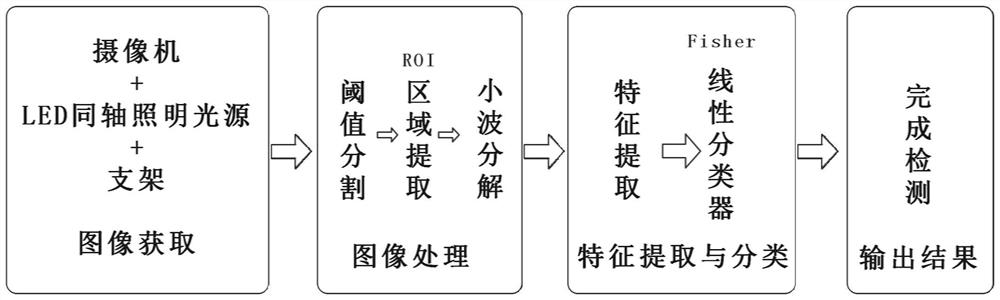

A technology of humidity sensor and detection method, which is applied in neural learning methods, instruments, image analysis, etc., can solve the problems of low detection accuracy and good product rate, time-consuming, low efficiency, etc., to reduce detection running time and improve detection efficiency , the effect of simplifying the algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

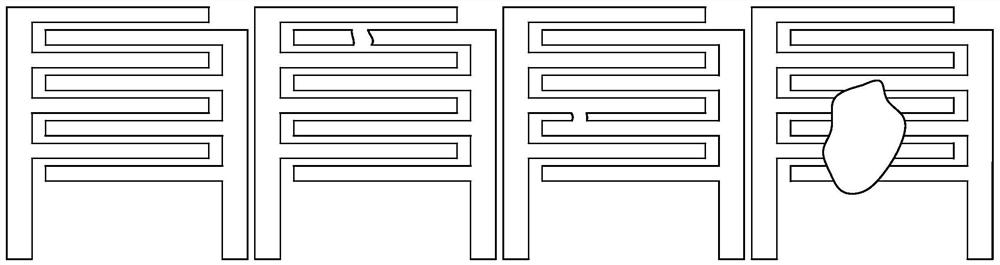

[0113] Humidity Sensor Printed Carbon Line Defect Detection Classification: In this embodiment, 720 images of printed carbon lines on ceramic substrates are selected for training and testing, some of which are images captured by cameras, and the other part is generated based on collected samples and specific environment simulations , Classify the images of carbon wire defects printed on ceramic substrates through the BP neural network, and use 480 sample images as training samples to extract features to train the BP neural network, among which 480 sample images are short circuit, open circuit, large area short circuit, normal The samples are all 180, and the remaining 240 are test samples for testing the classifier, which can be obtained as Figure 16 The test results shown.

[0114]Humidity sensor missing corner defect detection classification: In this embodiment, 60 images are used for missing corner detection, which are divided into two groups, of which 20 missing corner im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com