Method and system for reducing adhesive strength and associated pull-out stress

A technology of bonding strength and stress, applied in the direction of bonding methods, adhesives, material gluing, etc., can solve problems such as reducing part warping, low modulus, lack of absorbing stress, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

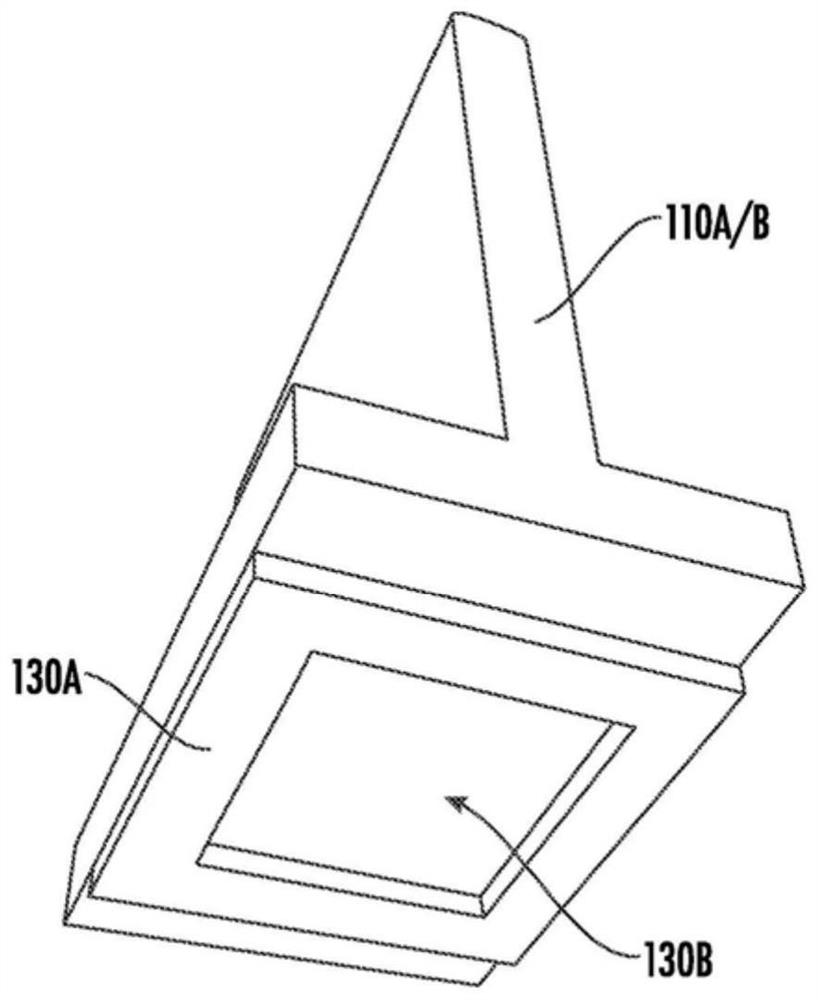

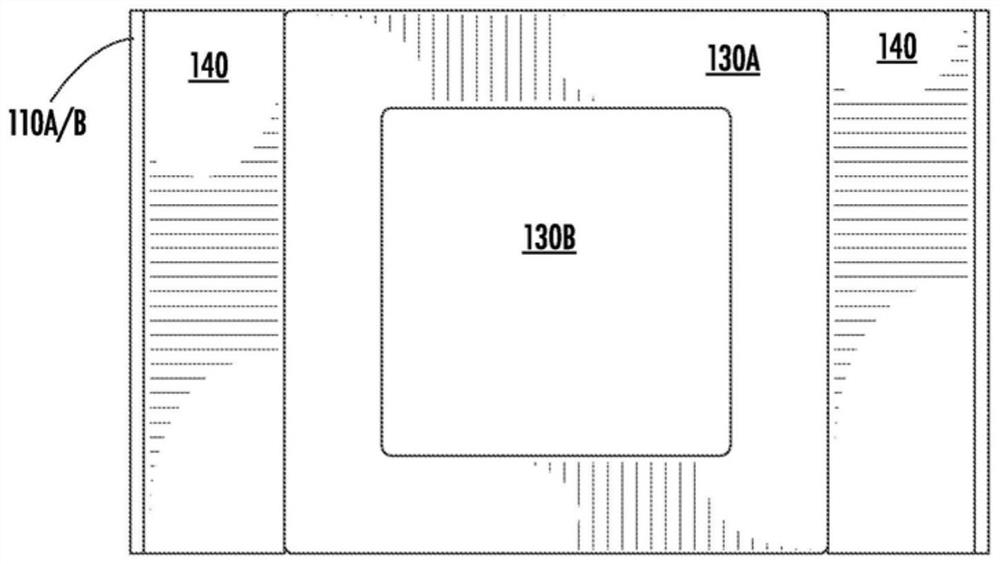

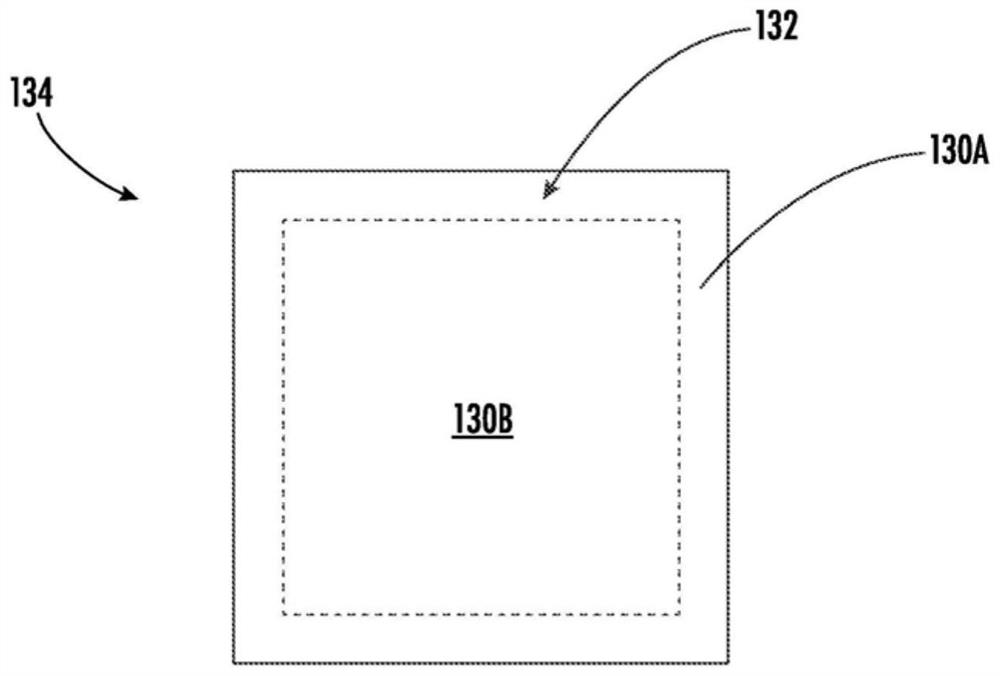

[0083]In a first exemplary embodiment disclosed herein, there is provided a method for forming an adhesive bond between at least two substrates that reduces the amount of pull required to separate the substrates when the substrates are separated from each other. Stress relief (eg, defined as force of removal divided by bonded surface area). The method includes adhesively bonding a plurality of substrates on bonding regions where a first bonding region has a first adhesive different from a second adhesive applied on a second bonding region. The bonding agent, the bonding strength of the second adhesive in the second bonding area is lower than the bonding strength of the first adhesive in the first bonding area. As used herein, bond strength is related (e.g., directly related) to the pull-off force required to separate adhesively bonded substrates, which means that it takes less time to separate substrates bonded with an adhesive of low bond strength. An adhesive with increased...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com