Separator for battery and method for producing same

A separator and battery technology, which is applied in the field of battery separator and its manufacturing, can solve the problems of polyolefin porous membrane rupture, etc., and achieve the effects of less water, heat shrinkage inhibition, and low rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

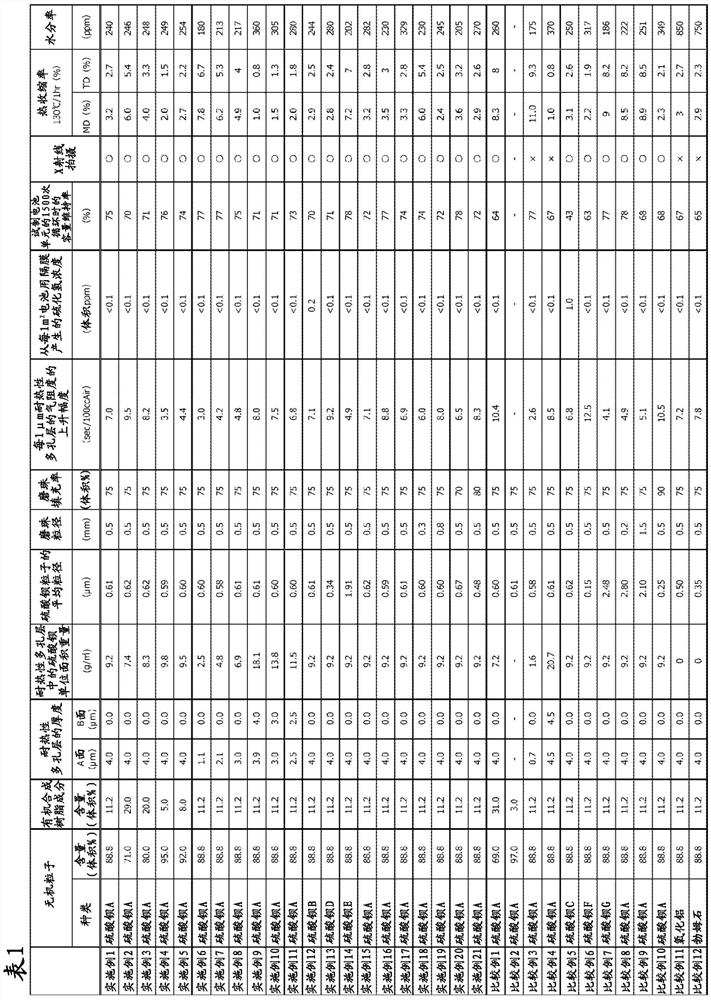

Examples

Embodiment 1

[0216] [Production of battery separator]

[0217] 1 part by weight of sodium carboxymethylcellulose was added to 100 parts by weight of water, and stirred at 600 rpm for 120 minutes with a three-in-one motor (manufactured by Toki Sangyo Co., Ltd.) equipped with dispersing blades. Furthermore, 1.14 parts by weight of the above-mentioned barium sulfate A was added with stirring to 100 parts by weight of water, followed by further stirring for 60 minutes to obtain a liquid mixture.

[0218] For the obtained mixed solution, using a bead mill disperser (Pico Mill PCM-LR manufactured by Asada Iron Works Co., Ltd.) and zirconia grinding beads (TORAYCERAM φ0.5 mm manufactured by Toray Co., Ltd.) with a grinding bead particle size of 0.5 mm, in Dispersion mixing was performed twice under the conditions of a bead filling rate of 75% by volume, a peripheral velocity of 10m / sec, and a flow velocity of 16kg / hr to obtain a masterbatch liquid.

[0219] 3.5 parts by weight of an acrylic resi...

Embodiment 2

[0223] The total of the barium sulfate particles and the organic synthetic resin components in the heat-resistant porous layer is set as 100% by volume, the barium sulfate particles are 71.0% by volume, and the organic synthetic resin components are 29.0% by volume (dispersant: 5.8% by volume, adhesive agent: 23.2 volume %), barium sulfate particles contained in the heat-resistant porous layer is 7.4g / m 2 , except that, it carried out similarly to Example 1, and obtained the separator for batteries.

Embodiment 3

[0225] The total of the barium sulfate particles and the organic synthetic resin component in the heat-resistant porous layer is set as 100% by volume, the barium sulfate particle is 80.0% by volume, and the organic synthetic resin component is 20.0% by volume (dispersant: 4.0% by volume, adhesive agent: 16.0% by volume), the barium sulfate particles contained in the heat-resistant porous layer are 8.3g / m 2 , except that, it carried out similarly to Example 1, and obtained the separator for batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com