Shallow-buried drip irrigation corn straw returning method

A technology of corn stalks and shallow burial, which is applied in the direction of soil preparation methods, applications, agricultural machinery and implements, etc., and can solve the problems of residues, poor seedling quality, affecting seeding quality and seedling emergence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

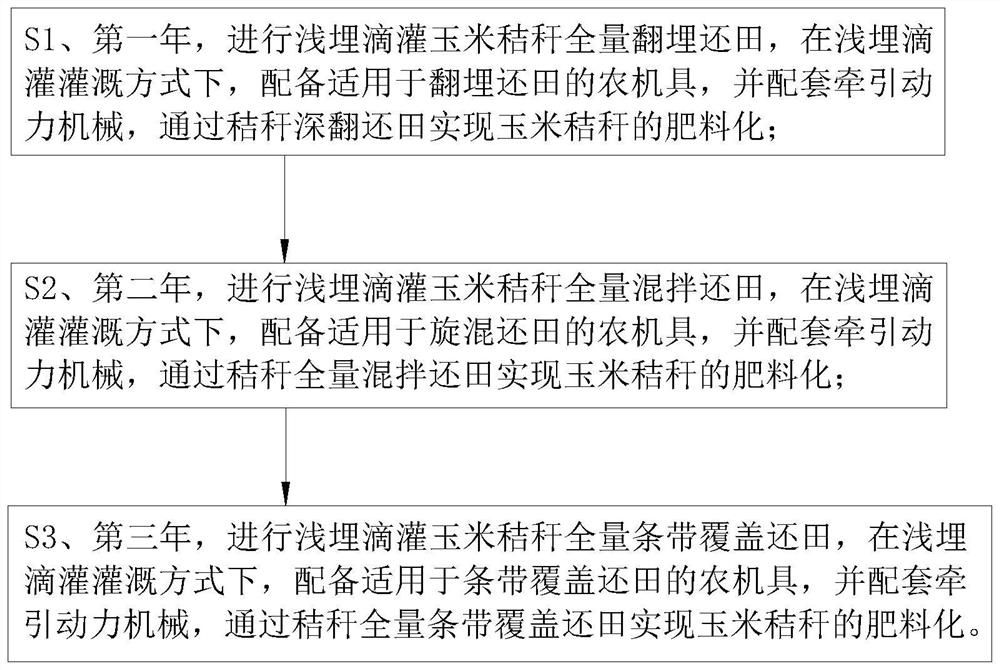

[0026] The first year: Shallow burial and drip irrigation of corn stalks fully buried and returned to the field technology model

[0027] In response to the warm and dry climate in Inner Mongolia Autonomous Region, insufficient surface water resources, large biomass of corn stalks, low crushing degree of straw, slow decomposition of straw returning to the field, and the fact that returning straw to the field is not conducive to sowing and emergence, and the occurrence of serious pests and weeds is serious. Under the shallow-buried drip irrigation method, optimize and improve corn harvesters, straw returning machines, hydraulic tilting plows, hydraulic harrows and other related agricultural machinery and equipment, and support traction power machinery, and realize the fertilizer application of corn straw through deep plowing and returning of straw to the field. The large amount of corn stalks, low utilization rate, and environmental pollution caused by straw incineration can ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com