Low-GI buckwheat fine dried noodles and preparation method thereof

A buckwheat and dried noodle technology, which is applied in dough forming and cutting equipment, dough extruder, food science and other directions, can solve the difficulty in industrialized production of buckwheat noodle with high addition of tartary buckwheat, which is easy to break in rolling, poor in noodle formability and poor in noodle formability. and other problems, to achieve the effect of controlling blood sugar rise rate, strong taste, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A buckwheat vermicelli produced by a twin-screw extruder, comprising the following parts by weight: 30 parts of buckwheat flour, 60 parts of wheat enriched powder, 5 parts of tremella powder, 3 parts of mulberry leaf extract, 2 parts of Artemisia annua powder .

[0028] A kind of method utilizing twin-screw extruder to produce buckwheat vermicelli, specifically comprises the steps:

[0029] Step 1: Raw material ratio: Select the corresponding raw materials according to the product formula.

[0030] Step 2: batching: materials are prepared according to the requirements of parts by weight.

[0031] Step 3: 60 parts of the mixture and 40 parts of industrial water are mixed at a high speed to obtain wet flour.

[0032] Step 4: Heating the three barrels of the twin-screw extruder. The first zone is 95°C, the second zone is 105°C, and the third zone is 70°C.

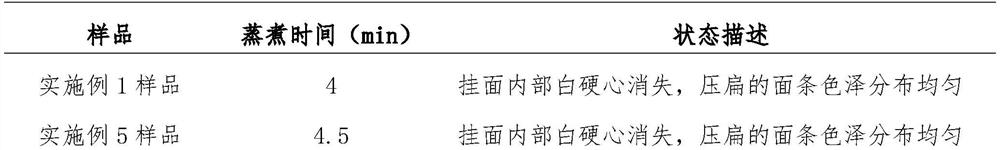

[0033] Step 5: Use a screw feeder to transport the wet flour prepared in Step 3 to an extruder for extrusion and ...

Embodiment 2

[0038] A buckwheat vermicelli produced by a twin-screw extruder, comprising the following parts by weight: 50 parts of buckwheat flour, 40 parts of wheat enriched powder, 3 parts of white fungus powder, 1 part of mulberry leaf extract, 6 parts of Artemisia annua powder .

[0039] A kind of method utilizing twin-screw extruder to produce buckwheat vermicelli, specifically comprises the steps:

[0040] Step 1: Raw material ratio: Select the corresponding raw materials according to the product formula.

[0041] Step 2: batching: materials are prepared according to the requirements of parts by weight.

[0042] Step 3: Perform high-speed mixing according to 70 parts of the mixture and 30 parts of industrial water to prepare wet flour.

[0043] Step 4: Heating the three barrels of the twin-screw extruder. The first zone is 95°C, the second zone is 105°C, and the third zone is 70°C.

[0044] Step 5: Use a screw feeder to transport the wet flour prepared in Step 3 to an extruder f...

Embodiment 3

[0049] A buckwheat vermicelli produced by a twin-screw extruder, comprising the following parts by weight: 70 parts of buckwheat flour, 20 parts of wheat enriched powder, 1 part of white fungus powder, 5 parts of mulberry leaf extract, 4 parts of Artemisia annua powder .

[0050] A kind of method utilizing twin-screw extruder to produce buckwheat vermicelli, specifically comprises the steps:

[0051] Step 1: Raw material ratio: Select the corresponding raw materials according to the product formula.

[0052] Step 2: batching: materials are prepared according to the requirements of parts by weight.

[0053] Step 3: Mix 80 parts of the mixture and 20 parts of industrial water at high speed to prepare wet flour.

[0054] Step 4: Heating the three barrels of the twin-screw extruder. The first zone is 95°C, the second zone is 105°C, and the third zone is 70°C.

[0055] Step 5: Use a screw feeder to transport the wet flour prepared in Step 3 to an extruder for extrusion and reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com