Production system for film agent

A production system and film technology, applied in the field of film quality control, can solve problems such as poor tablet weight or thickness monitoring and affecting film yield, so as to improve efficiency, improve product quality, avoid control differences and The effect of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

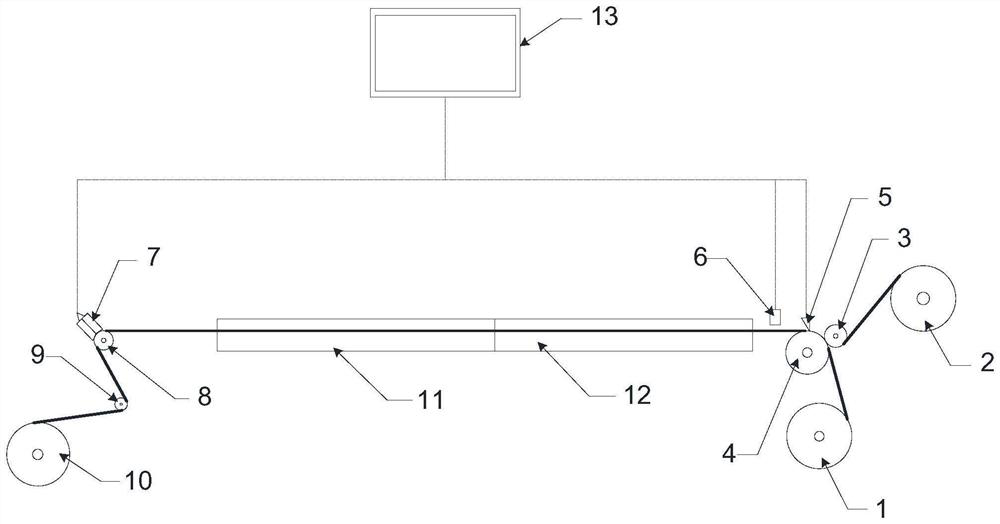

[0033] The invention provides a production system for film formulations, including a rolling wheel 14, a detector 6, a cutting knife 5, a reel 1 for qualified products, a drive wheel 3 for unqualified products and a rewinder 2 for unqualified products.

[0034] The rolling wheel I4 is used to convey the coated and dried medicinal film to the downstream process.

[0035] The detector 6 is arranged upstream of the rolling wheel I4 for detecting the thickness of the coated and dried drug film, and the detector 6 adopts an eddy current thickness measuring probe.

[0036] The cutting knife 5 is used to cut the film layer of the medicine film based on the detection result of the medicine film thickness, and the cutting knife 5 is arranged above the rolling wheel I4, and cooperates with the rolling wheel I4 to complete the cutting action.

[0037] The qualified product winding wheel 1 is used for winding and collecting the qualified medicine film passing through the rolling wheel I4,...

Embodiment 2

[0042] It is further improved on the basis of Example 1, and further includes a controller 13 , a coating blade 7 , a display, a film depositing roller 10 , a tensioning wheel 9 , a front heating device 11 and a rear heating device 12 .

[0043]The coating system for the film agent provided in this embodiment, along the conveying direction of the production line, successively set the film storage roller 10, the tension wheel 9, the roller II8, the front-end heating device 11, the rear-end heating device 12, and the roller I4 , Rewinding wheel 2 for qualified products, driving wheel 3 for unqualified products and rewinding wheel 2 for unqualified products. The cutting knife 5 is arranged above the rolling wheel I4, and the detector 6 is arranged above the medicine film between the rear-end heating device 12 and the rolling wheel I4.

[0044] The cutting knife is arranged on the moving part 1, and the cutting knife is driven by the moving part 1 to perform the cutting action.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com