Method for detecting amplitude of ultrasonic cutting tool

A technology of ultrasonic cutting and cutting tools, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of inability to obtain amplitude, poor timeliness, etc., to achieve easy calculation, less calculation process, and good timeliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

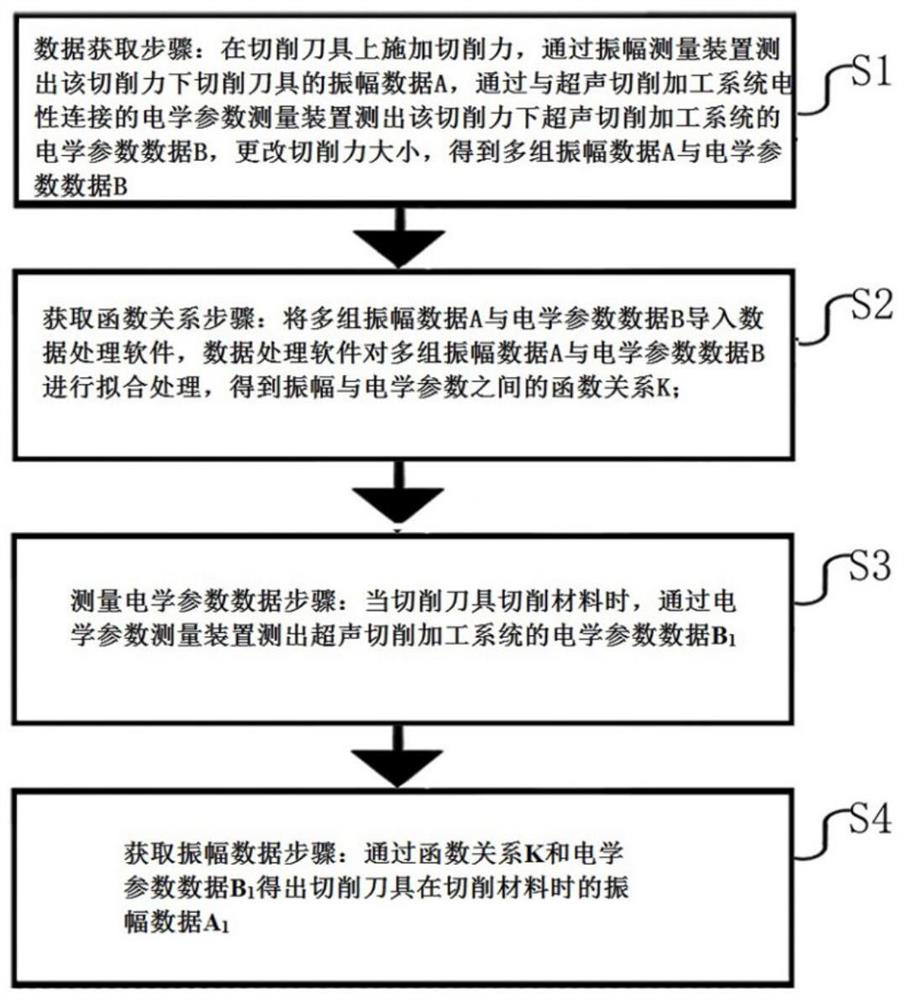

[0041] Example 1, such as figure 1 As shown, a method for detecting the amplitude of an ultrasonic cutting tool includes the following steps:

[0042] S1. Data acquisition step: apply cutting force on the cutting tool, measure the amplitude data A of the cutting tool under the cutting force through the amplitude measuring device, and measure the cutting force through the electrical parameter measuring device electrically connected with the ultrasonic cutting processing system Download the electrical parameter data B of the ultrasonic cutting processing system, change the cutting force, and obtain multiple sets of amplitude data A and electrical parameter data B;

[0043] S2. The step of obtaining the functional relationship: import multiple sets of amplitude data A and electrical parameter data B into the data processing software, and the data processing software performs fitting processing on multiple sets of amplitude data A and electrical parameter data B to obtain the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com