Fuel briquetting equipment for heat storage combustion

A technology of fuel briquetting and regenerative combustion, applied in the field of briquetting, can solve problems such as single function, and achieve the effects of improving work efficiency, improving practicability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

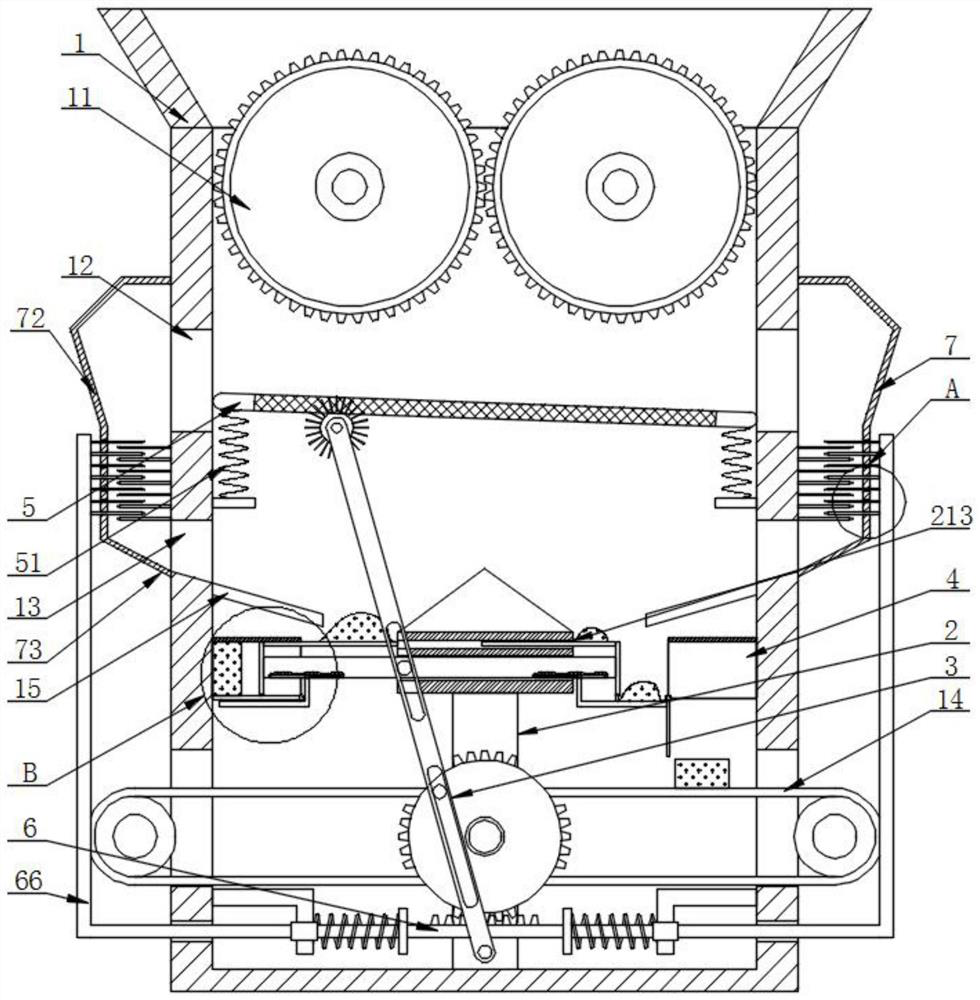

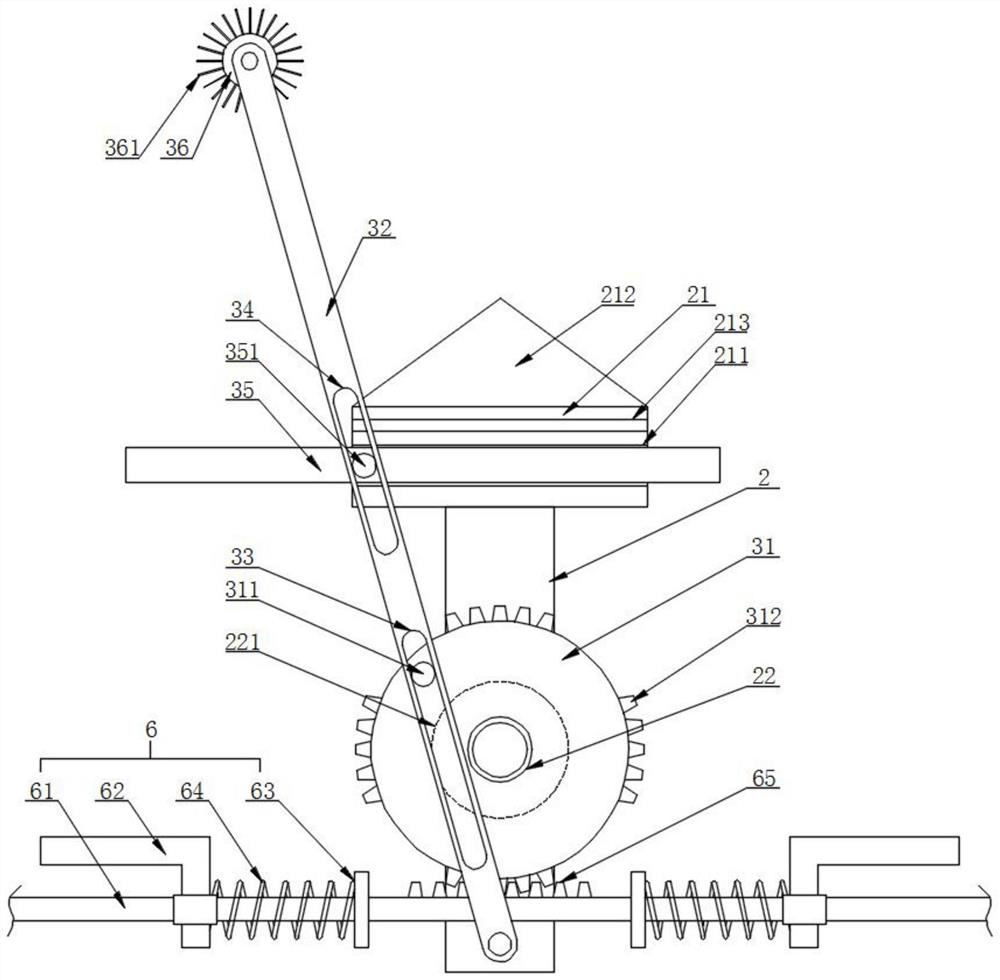

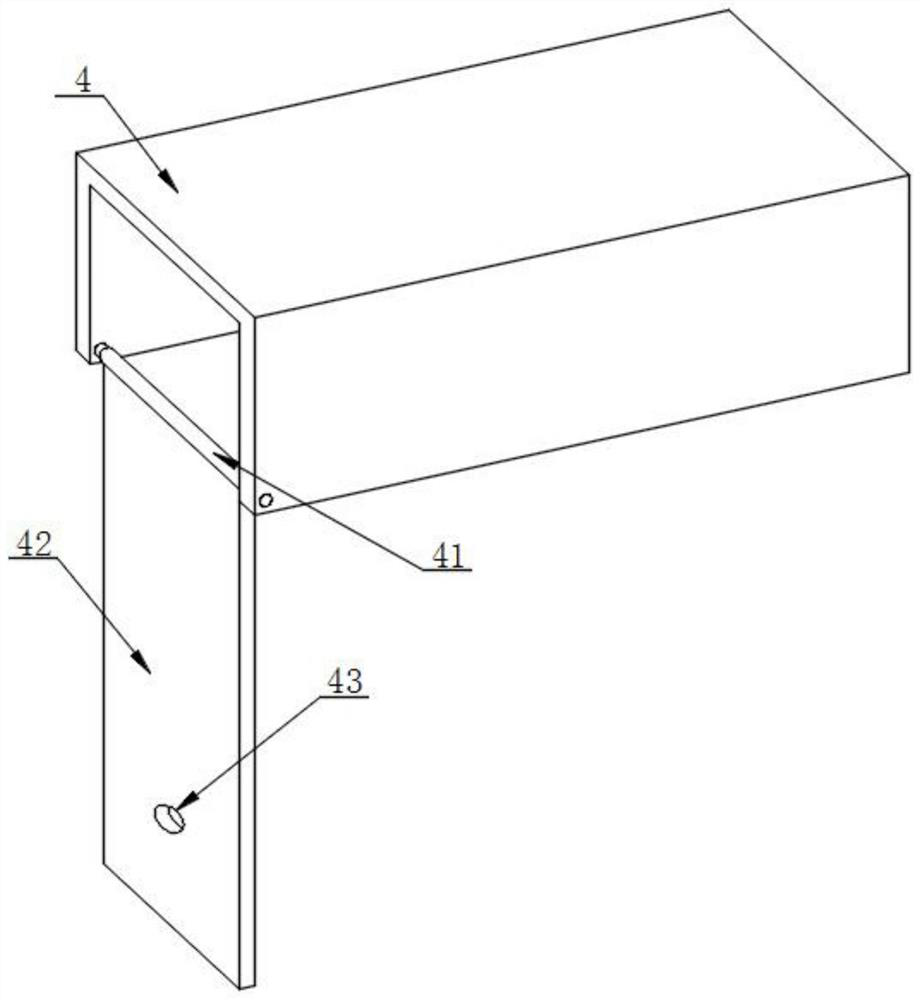

[0036] Refer to the attached Figure 1-6 , a fuel briquette equipment for regenerative combustion, comprising a box body 1, two crushing rollers 11 are installed in rotation between the two inner walls at the top of the inner cavity of the box body 1, and the two crushing rollers 11 are meshed and arranged, and the crushing rollers 11 Driven by an external motor, a filter screen 5 is provided below the two crushing rollers 11, a mold shell 4 is provided inside the box body 1, and a transmission device 14 is provided between the two inner walls at the bottom of the box body 1 for use For transporting the compressed fuel blocks to external collection and storage, two mold shells 4 are arranged symmetrically, and the two mold shells 4 are fixedly installed on the inner wall of the box body 1, and the box body A riser 2 is fixedly installed at the bottom of the inner cavity of 1, and a swing mechanism 3 is arranged on one side of the riser 2, and the swing mechanism 3 cooperates w...

Embodiment 2

[0043] Refer to the attached Figure 1-6 , a kind of fuel briquetting equipment for regenerative combustion, comprising a box body 1, two crushing rollers 11 are installed in rotation between the two inner walls at the top of the inner cavity of the box body 1, and a filter is arranged below the two crushing rollers 11. Net 5, the inside of the box 1 is provided with a mold shell 4, a transmission device 14 is provided between the two inner walls at the bottom of the box 1, and the mold shell 4 is provided with two symmetrically distributed, and the two The mold shells 4 are all fixedly installed on the inner wall of the box body 1, and the bottom of the inner cavity of the box body 1 is fixedly equipped with a riser 2, and one side of the riser 2 is provided with a swing mechanism 3, and the swing mechanism 3 and The mold shell 4 cooperates to realize fuel briquetting, and symmetrically arranged crushing boxes 7 are fixedly installed on both outer sides of the box body 1 .

...

Embodiment 3

[0050] Refer to the attached Figure 1-6 , a kind of fuel briquetting equipment for regenerative combustion, comprising a box body 1, two crushing rollers 11 are installed in rotation between the two inner walls at the top of the inner cavity of the box body 1, and a filter is arranged below the two crushing rollers 11. Net 5, the inside of the box 1 is provided with a mold shell 4, a transmission device 14 is provided between the two inner walls at the bottom of the box 1, and the mold shell 4 is provided with two symmetrically distributed, and the two The mold shells 4 are all fixedly installed on the inner wall of the box body 1, and the bottom of the inner cavity of the box body 1 is fixedly equipped with a riser 2, and one side of the riser 2 is provided with a swing mechanism 3, and the swing mechanism 3 and The mold shell 4 cooperates to realize fuel briquetting, and symmetrically arranged crushing boxes 7 are fixedly installed on both outer sides of the box body 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com