Textile fabric efficient printing and dyeing device

A high-efficiency technology for textile fabrics, applied in the field of high-efficiency printing and dyeing devices for textile fabrics, can solve problems such as surface defects of printing and dyeing fabrics, and achieve the effects of high work efficiency, economical work cost, and avoiding waste of resources and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

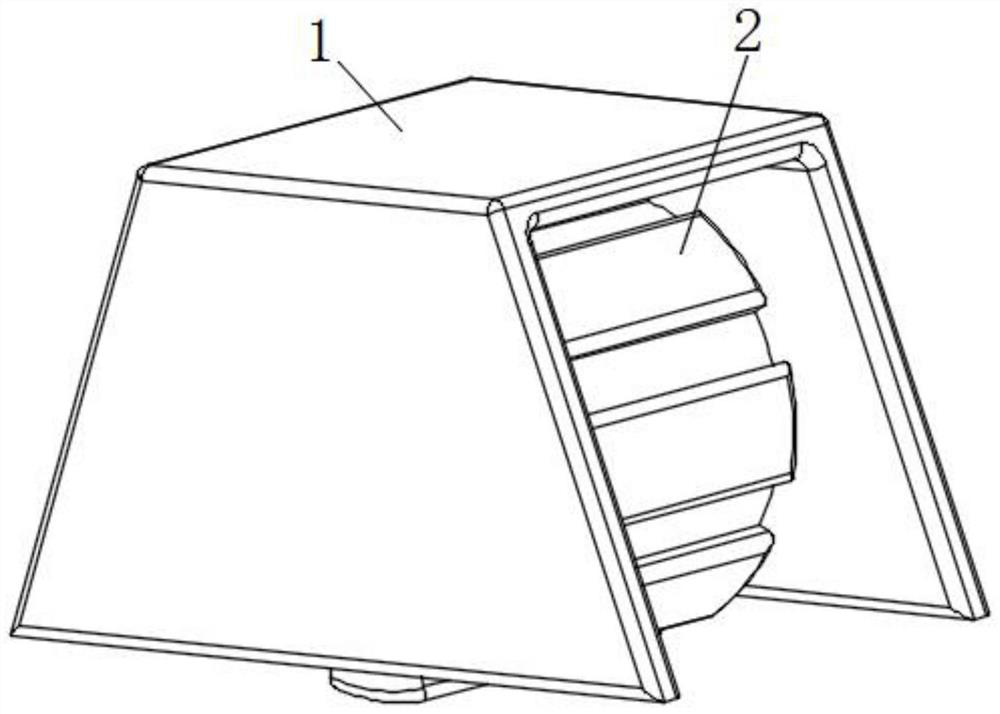

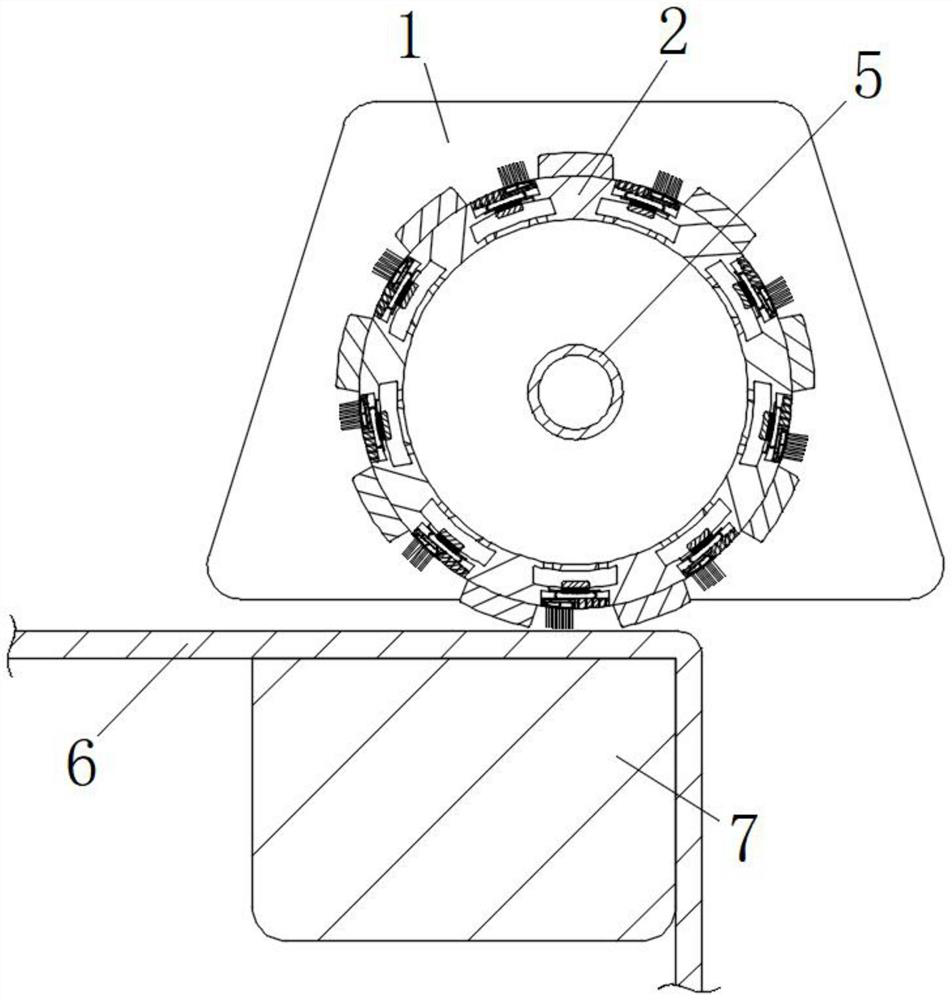

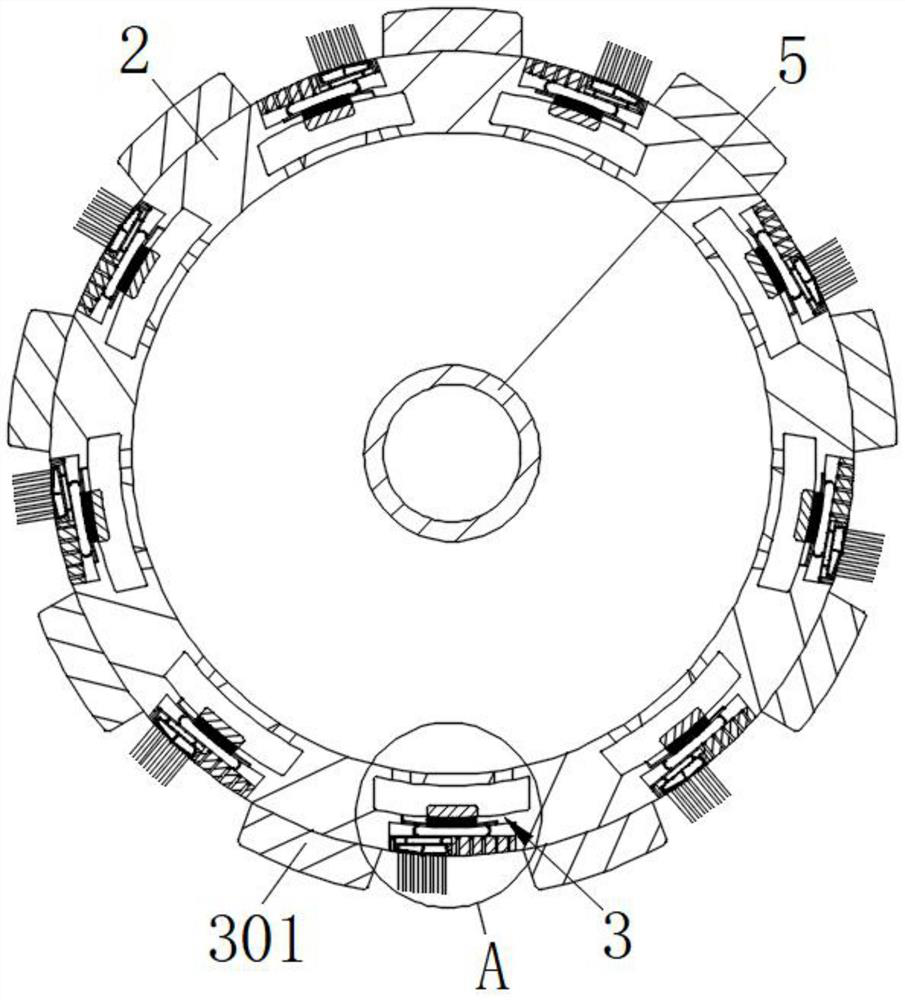

[0024] see Figure 1-6 , the present invention provides a technical solution: a high-efficiency printing and dyeing device for textile fabrics, including a frame body 1, a motor is fixedly connected to the front of the inner wall of the frame body 1, a drum 2 is fixedly connected to one end of the motor through a rotating shaft, and a hollow rod is fixedly connected to the back of the drum 2 5. The inside of the hollow rod 5 communicates with the inside of the drum 2. One end of the hollow rod 5 is fixedly connected to a hot air pump, and the back of the hot air pump is fixedly connected to the back of the inner wall of the frame body 1. The bottom of the drum 2 is in contact with the cloth 6, and the bottom of the cloth 6 is in contact with a placement table 7 , the inside of the cylinder 2 is provided with a printing and dyeing dust removal and cleaning mechanism 3;

[0025] The printing and dyeing dust removal and cleaning mechanism 3 includes a printing and dyeing plate 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com