Oil pump quality detection system

A detection system and oil pump technology, applied in pump testing, measuring devices, mechanical equipment, etc., can solve problems affecting the structural performance of pump oil, achieve the effect of fast and accurate placement, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

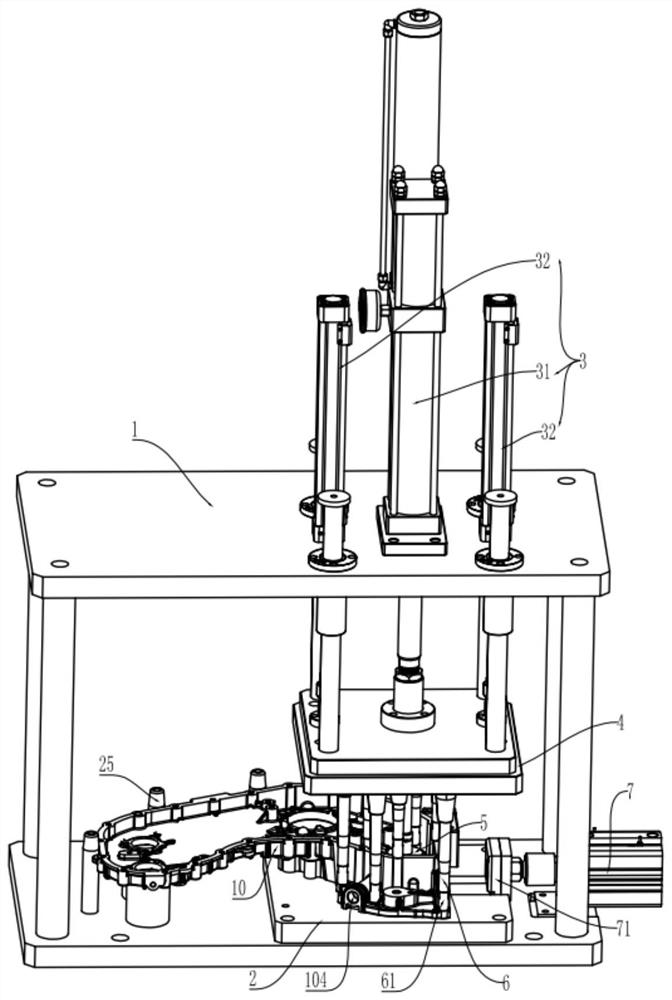

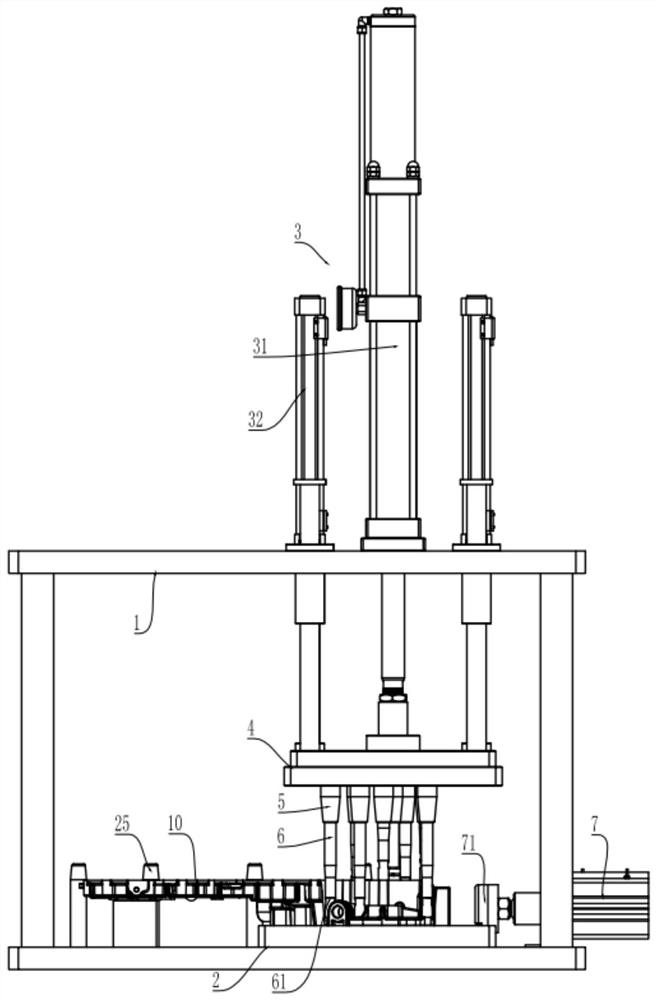

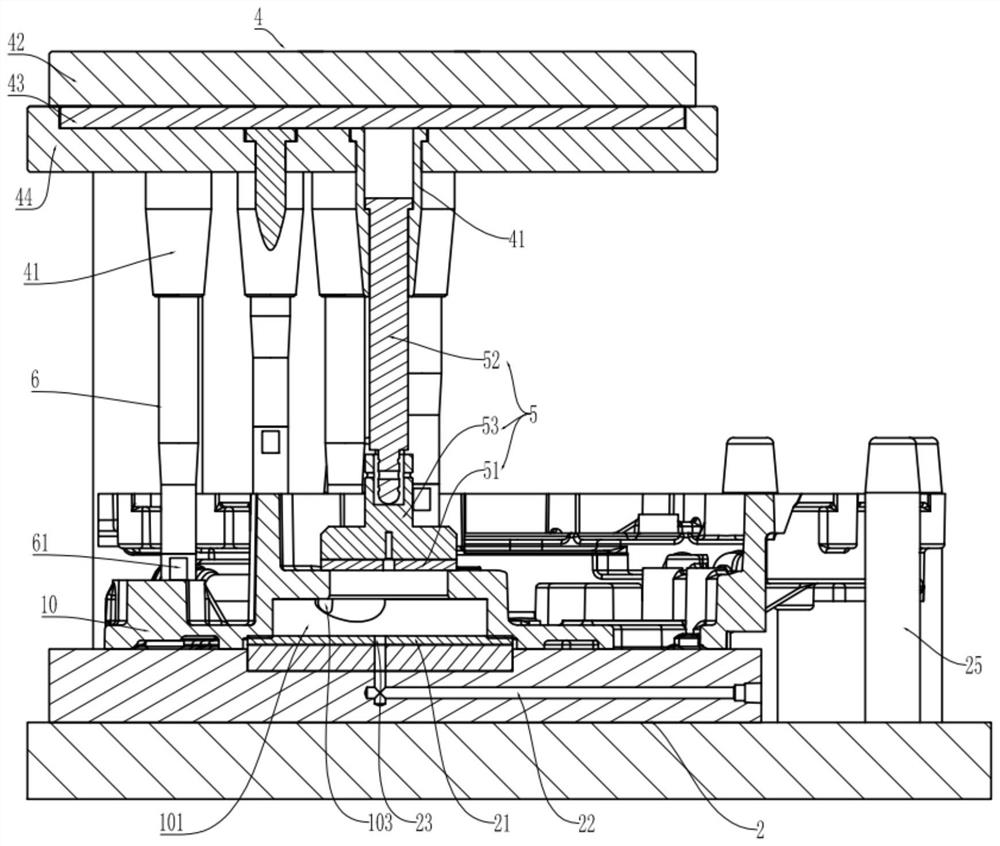

[0044] Embodiment one is basically as attached Figure 1 to Figure 7 As shown, an oil pump quality inspection system includes a pressure test device and a height difference detection device. The pressure test device is located in the previous process of the height difference detection device. Pressure valve opening pressure test, the height difference detection device is used to check the height difference between the end surface of the inner rotor 20 and the end surface of the pump oil chamber 101 after the oil pump structure of the inner rotor 20 and the outer rotor 30 is installed on the pump oil chamber 101 of the pump body , and the height difference between the end surface of the outer rotor 30 and the end surface of the pump oil chamber 101 is detected.

[0045] Pressure testing device, frame 1, test bench 2, pressing mechanism, air pressure adjustment module, pressure sensor and control module, the pressing mechanism includes a driver 3, a pressing plate 4, a pressing ...

Embodiment 2

[0064] Embodiment 2 On the basis of Embodiment 1, the height detection device is embodied, combining Figure 8 to Figure 11 , the height difference detection device comprises a workbench 8, a displacement sensor 40, a controller and a mobile device 9 that drives the displacement sensor 40 to move in space, and the displacement sensor 40 is connected to the output end of the mobile device 9, and the displacement sensor 40 and the mobile device 9 are all connected to the mobile device 9. The controller is connected, the controller is used to control the mover 9 to drive the displacement sensor 40 to move in space, the controller is used to store the height data collected by the displacement sensor 40, and the controller is connected to a second display.

[0065] The mover 9 adopts a three-dimensional mobile module, and the three-dimensional mobile module is used for the displacement sensor 40 to realize the movement of the X-axis, Y-axis and Z-axis. In this embodiment, the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com