Gaussian beam shaping device

A Gaussian beam and shaping device technology, which is applied in optics, optical components, instruments, etc., can solve the problems affecting the shaping effect, real focus energy concentration, induced sparks, etc., and achieve the effect of improving the shaping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

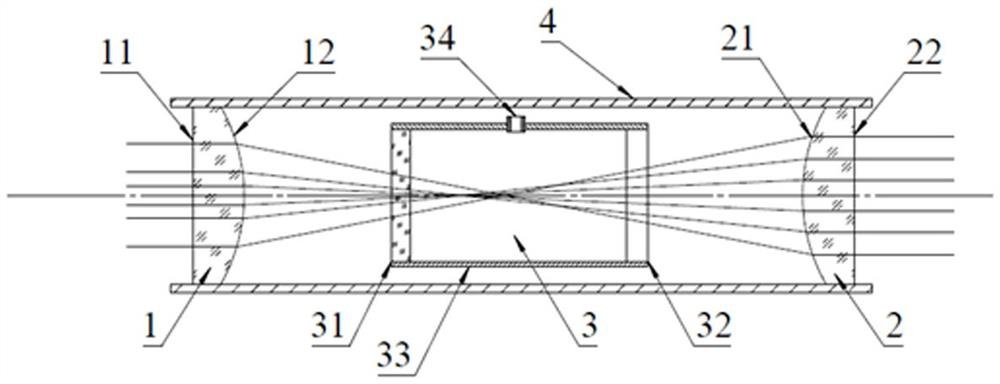

[0046] A shaping device for a Gaussian beam, comprising such as figure 1 As shown, the first lens 1, the second lens 2, the vacuum assembly 3, and the casing 4. The housing 4 supports the installation of the first lens 1 , the second lens 2 and the vacuum assembly 3 , and is installed inside the housing 4 . Light beams from different directions are gathered at the focal point by utilizing the positive focal length of the first lens 1 to perform preliminary compression shaping. Then it diverges at the focal point, and through the action of the second lens 2, the divergent light beam becomes a uniform parallel light beam to realize flattening of the Gaussian beam. Wherein the Gaussian beam is condensed in the vacuum component 3 after being shaped by the first lens 1 . Since the interior of the vacuum component is in a vacuum state, even if the heat gathers at the real focus, because there is no air and a medium for ionization, the formation of electric sparks is eliminated, an...

Embodiment 2

[0048] On the basis of embodiment 1, the vacuum assembly includes such as figure 1 As shown, the first high-permeability component 31 , the second high-permeability component 32 , the cavity 33 , and the exhaust valve 34 . The pumping valve 34 is used to evacuate the inside of the vacuum assembly, and the first high-transmittance component 31 is used for the Gaussian beam to enter the vacuum assembly 3, while preventing light from being reflected when passing through the first high-transparency component 31, thereby forming stray light. Affects the quality of the reshaped Gaussian beam. The second high-transparency component 32 is used for the Gaussian beam to leave the vacuum assembly 3 , and its function is the same as that of the first high-transparency component. The cavity 33 is used for assembling the first high-permeability component 31 , the second high-permeability component 32 and the exhaust valve 34 . Wherein, as long as the exhaust valve is not installed on the ...

Embodiment 3

[0051] On the basis of Embodiment 1, the first lens 1 and the second lens 2 adopt an aspherical structure. Such as figure 1 As shown, the first lens 1 has a first flat surface 11 and a first convex surface 12 , and the second lens 2 has a second convex surface 21 and a second flat surface 22 . In the actual production process, the first lens 1 and the second lens 2 only need to have a positive focal length. Only the above-mentioned setting method is easier to process and more convenient to operate, and it does not rule out that the first lens 1 and the second lens 2 have other shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com