Oral implant robot one-drill hole preparation operation method based on real-time temperature sensing

A technology of real-time temperature and operation method, applied in the field of non-disease treatment, can solve the problems of no temperature sensing function, excessive heat production, and the temperature of bone tissue in the cavity exceeds 47°C, which is conducive to collection and backfilling and reuse. The effect of reducing the risk of bone tissue burns and improving the efficiency of hole preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

[0041] refer to Figure 1 to Figure 9 , a method of drilling and preparing holes for an oral implant robot based on real-time temperature sensing, comprising the following steps:

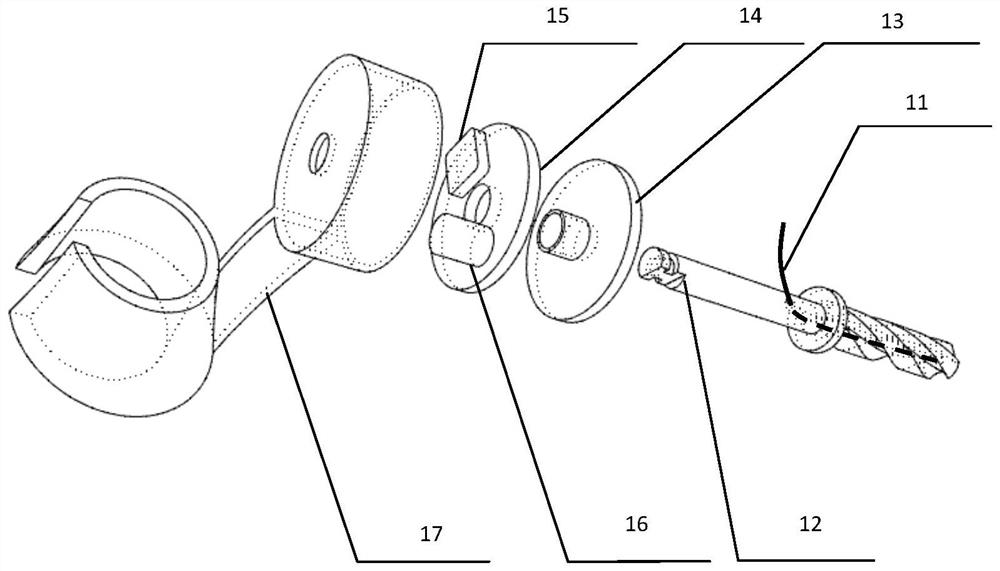

[0042] 1) Temperature sensing drill selection

[0043] Choose the diameter and length of the temperature-sensing drill according to the implant model in the implant plan. Temperature-sensing drills with different diameters will affect the heating rate of the heat source in the temperature field model;

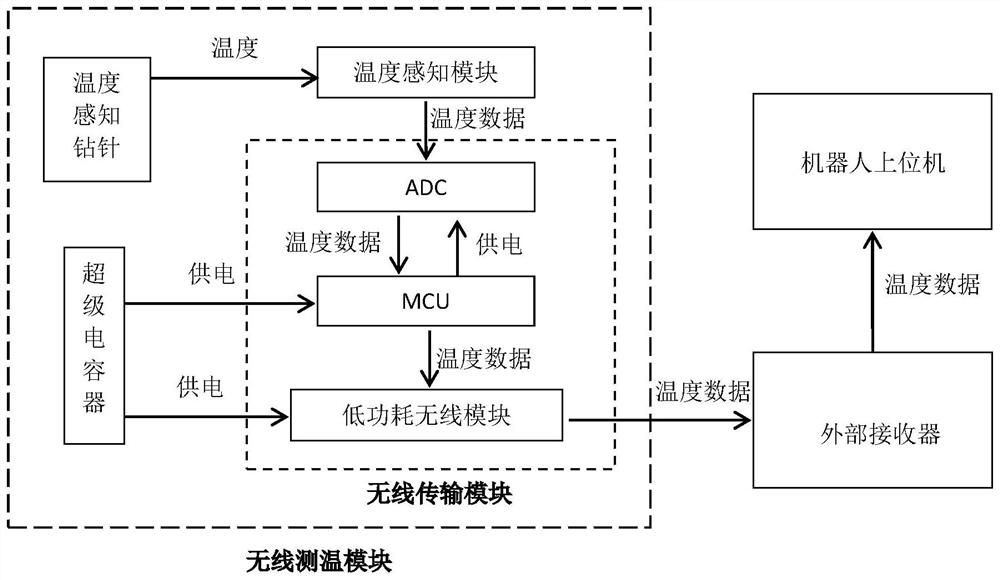

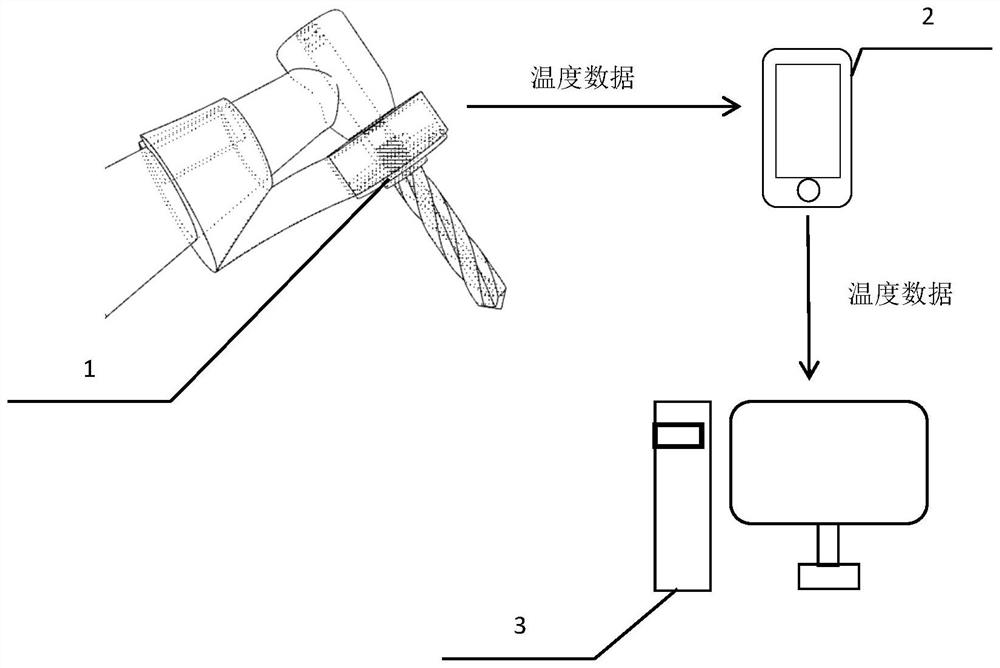

[0044] 2) Wireless temperature measurement module installation

[0045] Install the wireless temperature measurement module on the planting phone and check the stability of the connection;

[0046] 3) Wireless temperature measurement module transmission test

[0047] Power on the wireless temperature measurement module before preparing the hole, and at the same time start the planting mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com