Graphite copper bush processing device

A processing device and copper sleeve technology, applied in the field of graphite, can solve the problems of long time-consuming, uneven coating, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

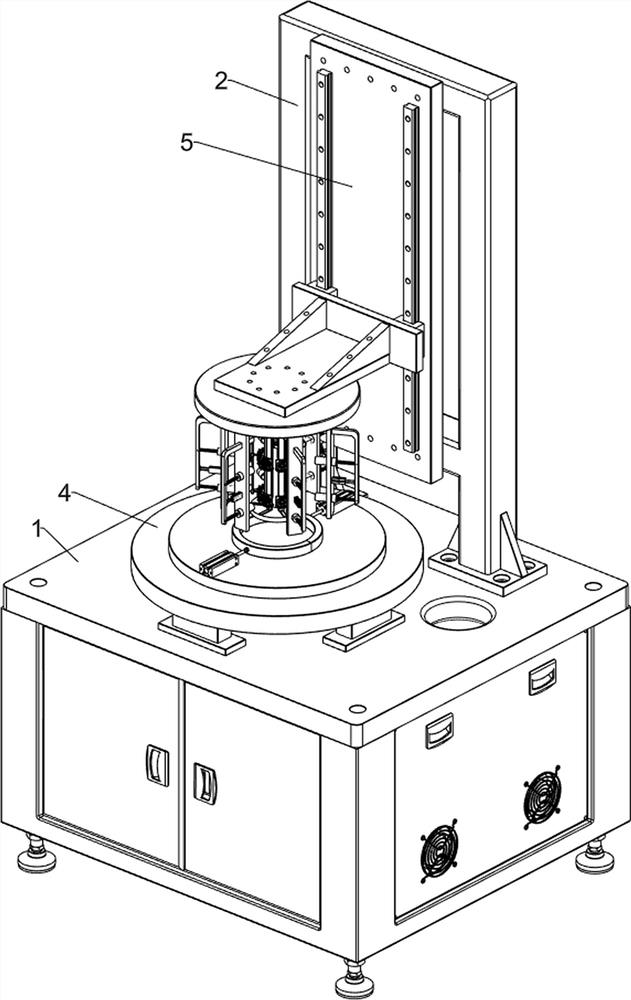

[0032] A graphite copper sleeve processing device, such as Figure 1-9As shown, it includes a frame 1, a support frame 2, a rotating system 4 and an inlaid gluing system 5; the upper side of the frame 1 is connected with a support frame 2; the upper side of the frame 1 is connected with a rotating system 4, and the rotating system 4 is located in the support The front side of the frame 2; the front side of the support frame 2 is connected with an inlay coating system 5.

[0033] When in use, first place a graphite copper sleeve processing device at the required position, place the frame 1 in a stable position, first manually put cylindrical graphite into the mosaic coating system 5, and then put the graphite to be treated The copper sleeve 3 is placed on the rotating system 4, the inlay coating system 5 is controlled to descend, and then the rotating system 4 is controlled to rotate the graphite to the required angle, so that the cylindrical graphite can smoothly enter the gro...

Embodiment 2

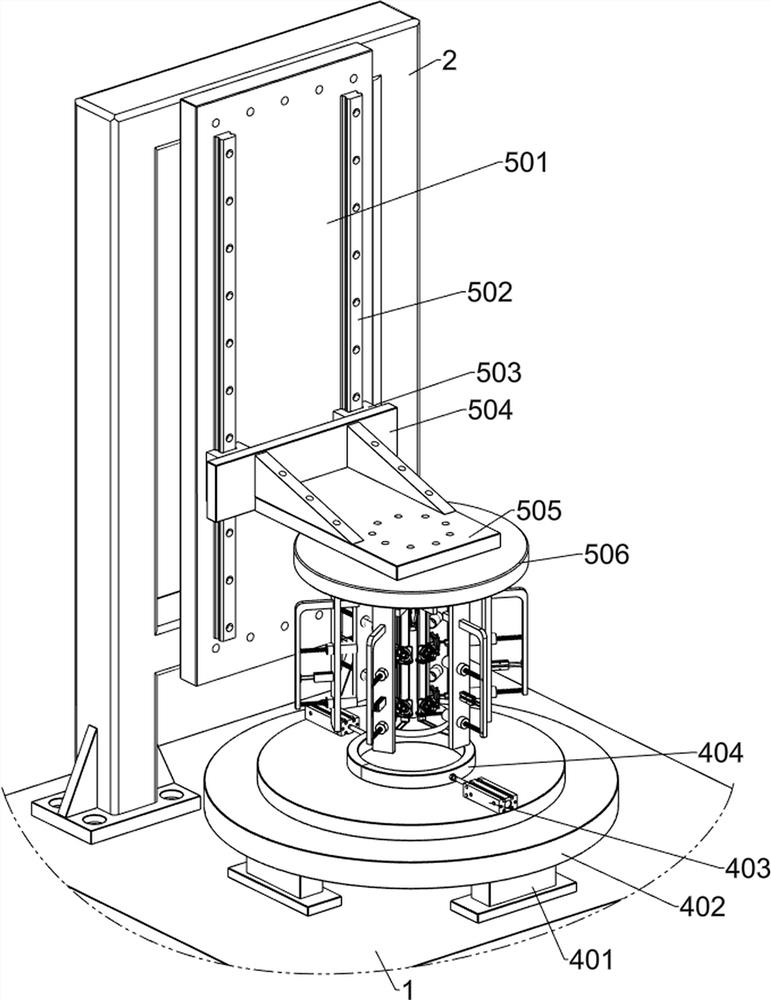

[0035] On the basis of Example 1, as Figure 1-9 As shown, the rotating system 4 includes a base 401, an electric turntable 402, a first electric push rod 403 and an arc-shaped clamping block 404; four bases 401 are fixedly connected to the upper side of the frame 1, and the four bases 401 are located in the support frame 2. Front; the upper sides of the four bases 401 are fixed with an electric turntable 402; the upper front and the upper rear of the electric turntable 402 are bolted with a first electric push rod 403; the two first electric push rods 403 pass through the telescopic part An arc-shaped clamping block 404 is fixed to each, and two arc-shaped clamping blocks 404 are used to clamp the graphite copper sleeve 3 to be processed.

[0036] The arc-shaped clamping block 404 is adapted to the degree of curvature of the outer surface of the graphite copper sleeve 3 to be processed, and is used for clamping the graphite copper sleeve 3 to be processed.

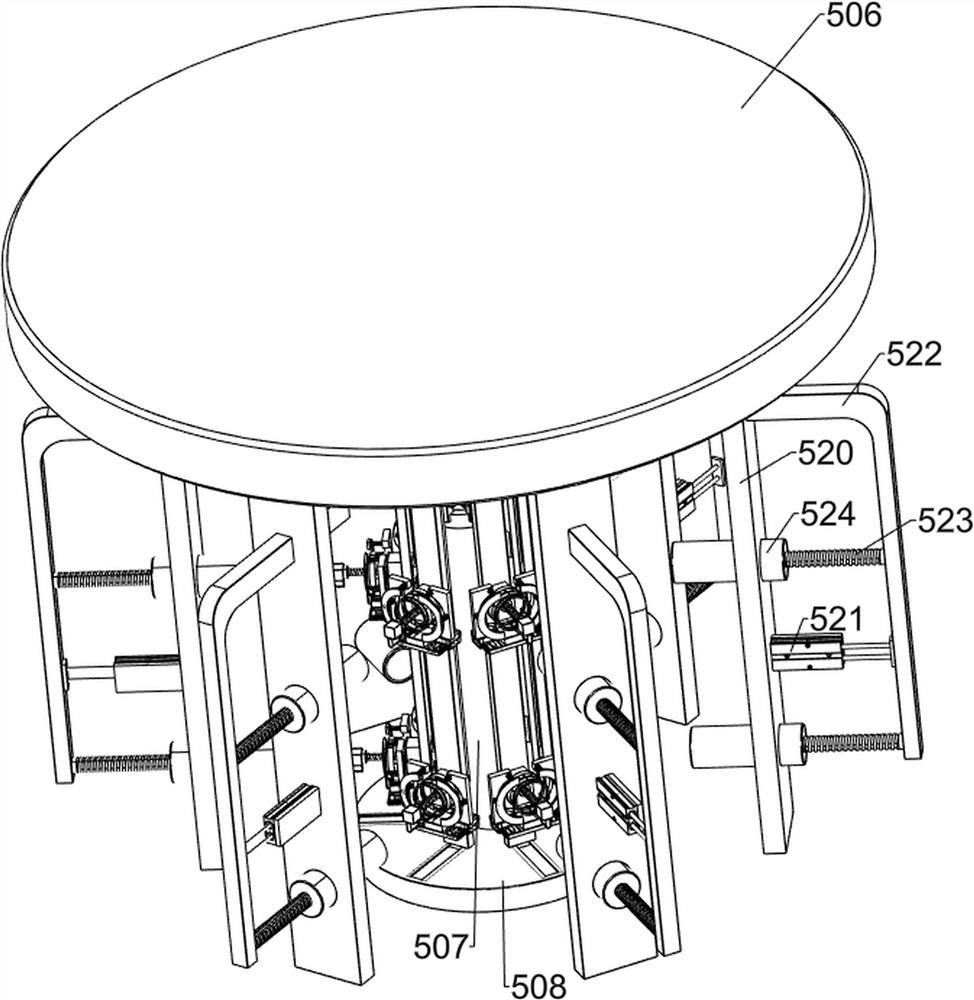

[0037] The inlay...

Embodiment 3

[0041] On the basis of Example 2, as Figure 10-12 As shown, it also includes a glue removal system 6; the inlaid glue application system 5 is connected with twelve glue removal systems 6, and the twelve glue removal systems 6 are divided into two layers, and the upper and lower layers have six glue removal systems 6, which are in the form of etc. The distance from the annular array is distributed; the glue removal system 6 in front of the upper layer includes a fixed block 601, a first spring column 602, a circular ring 603, a second mounting plate 604, a second electric slide rail 605, a second electric slider 606, Two fixed plates 607, chute block 608, sliding column 609, arc plate 610, second spring column 611, arc scraper 612 and collection box 613; the outer surface of the sliding seat 517 is fixed with a fixed block 601; the fixed block 601 The front side is fixed with six first spring columns 602, and the six first spring columns 602 are distributed in an equidistant a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com